Blog

Recent Posts

Copperhill Technologies and Their J1939 Gateways

Posted by on

Copperhill Technologies is a company known for providing high-quality, reliable networking solutions for industrial and transportation applications. Among its range of offerings, their J1939 gateways stand out as key components for connecting devices that use the SAE J1939 protocol, a standard that is integral to modern heavy-duty vehicles and industrial machinery.

Copperhill Technologies is a company known for providing high-quality, reliable networking solutions for industrial and transportation applications. Among its range of offerings, their J1939 gateways stand out as key components for connecting devices that use the SAE J1939 protocol, a standard that is integral to modern heavy-duty vehicles and industrial machinery.

Understanding SAE J1939

The SAE J1939 protocol is a set of standards used for communication between electronic control units (ECUs) in heavy-duty vehicles, such as trucks, buses, and construction equipment. It is based on the Controller Area Network (CAN) bus, which allows for real-time communication between different devices within a vehicle or machine. J1939 enables the exchange of crucial data, including engine parameters, speed, fuel consumption, diagnostic information, and more.

This protocol is widely used in the automotive and transportation industries due to its robustness and reliability in harsh environments, making it ideal for large vehicles and machinery. However, despite its widespread use, integrating devices that communicate via J1939 with other industrial networks or systems can pose significant challenges. This is where Copperhill Technologies' J1939 gateways come into play.

Copperhill Technologies' J1939 Gateways

Copperhill Technologies offers a range of J1939 gateways designed to simplify the integration of J1939-enabled devices with other networks and systems. These gateways serve as intermediaries between J1939-based systems and other communication protocols, such as Modbus, Ethernet/IP, or CANopen. This allows businesses and organizations to bridge different communication standards, enabling seamless data exchange between devices and systems that might otherwise be incompatible.

The J1939 gateways provided by Copperhill Technologies are designed with several features in mind:

- Protocol Conversion: The gateways can convert J1939 messages to other protocols and vice versa, facilitating integration with other devices and systems that use different communication standards. This is particularly useful for applications where J1939-based vehicles need to interface with enterprise-level systems or other networked devices.

- Data Monitoring and Diagnostics: These gateways provide robust monitoring capabilities, allowing users to track the performance of J1939-enabled devices in real time. Additionally, they can collect diagnostic information, helping with preventive maintenance and troubleshooting by providing insights into the health and performance of the systems.

- Scalability and Flexibility: Copperhill Technologies' gateways are designed to scale according to the needs of different industries. Whether for small fleets or large-scale industrial machinery networks, the gateways can handle a range of data loads and network configurations, ensuring that they can adapt to evolving requirements.

- Real-Time Communication: The gateways are built for real-time data exchange, ensuring that crucial information is transmitted quickly and reliably. This is essential for applications in industries where real-time monitoring of systems and components is critical, such as in fleet management, diagnostics, and control systems.

- Customization Options: Copperhill Technologies offers customization services, allowing the J1939 gateways to be tailored to the specific needs of clients. This includes the configuration of communication parameters, the addition of custom functionality, and the adaptation to unique system requirements.

Applications of J1939 Gateways

The J1939 gateways from Copperhill Technologies have a wide range of applications, particularly in industries that rely heavily on vehicles and machinery. Some notable areas of use include:

- Fleet Management: For companies managing large fleets of trucks, buses, or construction vehicles, Copperhill's J1939 gateways allow for centralized data monitoring, helping to track vehicle performance, fuel efficiency, and maintenance needs. This can improve fleet management, reduce downtime, and enhance operational efficiency.

- Industrial Automation: In industries where heavy machinery operates, such as manufacturing or mining, the gateways enable seamless communication between J1939-enabled machines and industrial control systems. This enhances the ability to monitor machine health, integrate with other automation equipment, and improve overall productivity.

- Telematics and IoT: J1939 gateways are also used in telematics and Internet of Things (IoT) applications, where vehicles and machines are part of a larger network of connected devices. By integrating J1939 systems with broader networks, organizations can collect and analyze data remotely, allowing for more informed decision-making and predictive maintenance.

Conclusion

Copperhill Technologies' J1939 gateways play a critical role in enabling the interoperability of J1939-enabled devices with other networks and systems, enhancing communication and data exchange across a range of industries. With features such as protocol conversion, real-time communication, and scalable solutions, these gateways are essential tools for organizations that need to connect vehicles, machinery, and control systems. As industries continue to evolve, Copperhill Technologies' J1939 gateways provide the flexibility and reliability needed to support the growing demand for integrated, data-driven solutions in industrial and transportation applications. More Information...

SAE J1939 Starter Kit and Network Simulator

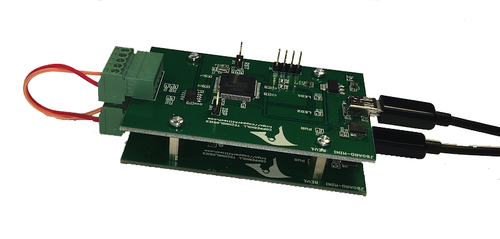

Our JCOM.J1939 Starter Kit and Network Simulator was designed to allow experienced engineers and beginners to experiment with SAE J1939 data communication without needing to connect to a real-world J1939 network, i.e., a diesel engine.

To establish a network, you need at least two nodes. This applies especially to CAN/J1939, where the CAN controller will shut down after transmitting data without receiving a response. Therefore, our jCOM.J1939 Starter Kit and Network Simulator consist of two J1939 nodes: our jCOM.J1939.USB, an SAE J1939 ECU Simulator Board with USB Port. More Information...

Improvements to our JCOM1939 Monitor & Simulation Software for Windows

Our SAE J1939 gateways are steadily gaining popularity, so we developed a dedicated website that focuses on the associated JCOM1939 Monitor Software for Windows. Since July of this year, we have added new features, some small and some significant improvements. With version 3.50.00, we have ceased support for older gateways, specifically those sold before 2022. The processors in [...]

JCOM1939 Monitor Pro - SAE J1939 Data Monitoring, Recording

Our SAE J1939 to USB/Bluetooth gateway and the SAE J1939 Starter Kit are designed to work seamlessly with our JCOM1939 Monitor Pro Software for Windows, a free download. This combination is key to ensuring your purchased product's optimal performance and overall satisfaction. For your convenience, we have meticulously crafted a dedicated website. This one-stop hub houses [...]

Diesel Engine Fluid (DEF) Sensor Simulator - Background Info

Before Reading, Please Consider! The DEF Sensor Simulator is not a ready-made product. It was developed by a group of automotive engineers as a concept to bypass faulty DEF sensors. It consists of a list of components with an associated control code, and you will need to assemble the simulator yourself. These engineers selected a component offered [...]

SAE J1939 250k/500k Baudrate Converter with Arduino Due

The introduction of 500 Kbps (see SAE J1939/14) as an alternative to 250 Kbps, required clarifications on how to solve problems that come with incorporating devices supporting different baud rate settings in the same network. One solution comes with automatic baud rate detection. The SAE J1939/16 document outlines the methods used to detect the baud rate [...]

SAE J1939: Simulation of Analog and Digital Signals with the JCOM1939 Monitor Software

The JCOM1939 Monitor Software is ideal for monitoring, recording, analyzing, and simulating SAE J1939 data traffic. The system works in combination with our SAE J1939 gateways. This comprehensive and easy-to-use, easy-to-understand Windows software displays not only SAE J1939 data traffic but also scans the network, simulates an ECU (incl. full node address negotiation features), and responds [...]

A New Generation of SAE J1939 Gateway, ECU Simulator, and Starter Kit

Like many other businesses, we have to deal with the global shortage of electronic components. For instance, the NXP LPC 17xx processors we used for our SAE J1939 gateways and the starter kit are not available at this time. Even worse, there is no reliable information if/when production resumes. This situation forced us to rethink [...]

SAE J1939 Data Recorder - Programming And Data Retrieval

The following is an update on our activities regarding our development of an SAE J1939 data recorder. The development affects two of our devices, the SAE J1939 Gateway Module With USB Port, RTC, MicroSD Memory Card and the SAE J1939 Gateway And Data Logger With Real-Time Clock. Both gateways are supported by our free-of-charge jCOM1939 Monitor, an SAE J1939 [...]

Classical CAN, CAN FD, And LIN Kit Simulates Devices And Networks For SAE J1939, NMEA 2000, CANopen

Warwick Control Technologies has released a development kit that enables users to simulate Classical CAN, CAN FD, and LIN devices and networks. It also supports the simulation of SAE J1939, NMEA 2000, and CANopen devices and networks. The kit comes with the Kvaser Hybrid Pro two-channel interface to test Classical CAN, CAN FD, and LIN systems through [...]

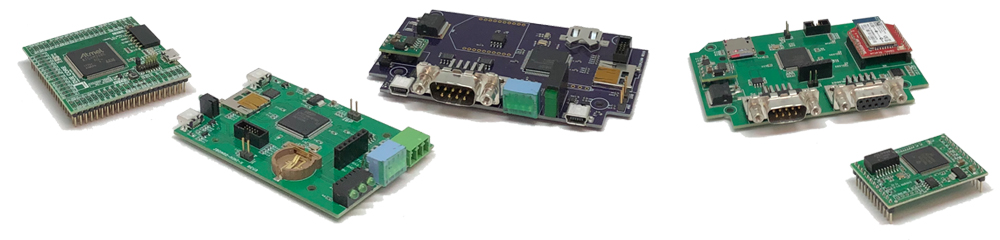

SAE J1939 Data Traffic Simulation, Monitoring And Data Logging Devices

Copperhill Technologies offers various SAE J1939 data traffic simulation and monitoring devices that also support data logging. All of these devices are based on industrial-strength hardware, operating under an extended temperature range of -40 to +85 Celsius and making them suitable for operation within offroad vehicles and lab test conditions. The JCOM series of SAE J1939 [...]

Loading... Please wait...

Loading... Please wait...