Blog

Recent Posts

Comparing SAE J1939 Baud Rates: Evaluating 250k vs. 500k for Modern Vehicle Networks

Posted by on

For years, SAE J1939 has been synonymous with heavy-duty vehicle networking, and 250k baud has been the de facto standard. But as vehicles grow more connected and data-intensive—think emissions controls, advanced diagnostics, telematics, and electrification—the question arises: is 250k still enough?

For years, SAE J1939 has been synonymous with heavy-duty vehicle networking, and 250k baud has been the de facto standard. But as vehicles grow more connected and data-intensive—think emissions controls, advanced diagnostics, telematics, and electrification—the question arises: is 250k still enough?

The recent discussion around adding a 500k baud rate to the J1939 standard aims to answer that very question.

The Case for 500k Baud

At 250k baud, J1939 provides reliability and robustness in noisy environments, which is why it has been trusted in trucking, agriculture, and construction for decades. However, as electronic control units (ECUs) multiply and applications demand faster updates, bandwidth pressure becomes a real bottleneck.

Moving to 500k baud essentially doubles the available bandwidth, reducing latency and allowing more messages per second without overloading the bus. This makes it particularly relevant for modern vehicles where real-time data exchange is becoming mission-critical.

Connectors and Hardware Updates

A faster baud rate isn’t just about firmware updates—it also affects the physical layer. Newer 9-pin Deutsch connectors (sometimes referred to as “Type II”) have been introduced to help distinguish 500k-capable systems from legacy 250k installations. These connectors ensure proper compatibility while reducing the risk of mismatched connections in mixed environments.

Consequences for System Design

Adopting 500k baud brings both opportunities and challenges:

-

Performance Gains: Higher throughput for diagnostics, control, and logging.

-

Backward Compatibility: Many systems will need dual-support (250k and 500k), especially during transition phases.

-

Tooling and Testing: Diagnostic tools, CAN gateways, and sniffers must be updated to handle both rates.

-

Standards Alignment: Engineers will need to consider how 500k interacts with higher-speed CAN FD and Ethernet-based standards already emerging in the industry.

Neutral Ground: 250k vs. 500k

| Feature | 250k Baud (Traditional) | 500k Baud (New Option) |

|---|---|---|

| Bandwidth | Baseline | ~2x higher |

| Latency | Moderate | Lower |

| Reliability | Proven in harsh environments | Still robust, but less field history |

| Compatibility | Universal | Requires updated connectors & tools |

Conclusion

The move to 500k baud doesn’t replace 250k—it complements it. Legacy systems will continue to operate at 250k, but 500k gives engineers more flexibility to design for the future without abandoning the rugged reliability J1939 is known for.

If you’re interested in a deeper technical dive into the necessity, connectors, and consequences of adding 500k baud, check out our full report.

For more details, see our post SAE J1939 Baud Rate Options: A Technical Comparison of 250k and 500k...

SAE J1939 Starter Kit And Network Simulator

SAE J1939 Starter Kit And Network Simulator

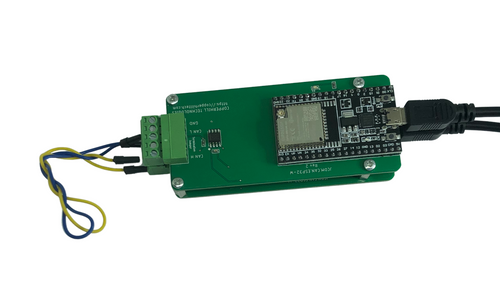

Our JCOM.J1939 Starter Kit and Network Simulator is built for both seasoned engineers and beginners who want to explore SAE J1939 data communication without relying on a real-world vehicle network such as a diesel engine.

To create a functioning network, you always need at least two nodes. This requirement is particularly important with CAN/J1939, where a single CAN controller will shut down if it transmits data but receives no response.

That’s why our Starter Kit includes two fully functional J1939 nodes. At its core is the JCOM.J1939.USB, an SAE J1939 ECU Simulator Board with a USB interface. Together, these nodes provide a self-contained test environment where you can send, receive, and analyze J1939 messages, experiment with network traffic, and develop applications — all without connecting to an actual engine or vehicle system. More information...

CAN Bus and SAE J1939: A Beginner’s Guide to Network Design

If you’ve ever worked with industrial machines or diesel engines, chances are you’ve heard of CAN bus and SAE J1939. These two go hand-in-hand when it comes to reliable, real-time communication between control units. Let’s break down the essentials of how these networks are designed and why they matter. What Is CAN Bus? CAN (Controller Area Network) [...]

Bridging the Gap: J1708 to J1939 Gateways for Diesel Engine Retrofits

Upgrading older diesel vehicles to support modern digital dashboards and telematics systems often requires translating legacy communication protocols. Specifically, many older heavy-duty vehicles use SAE J1708 with the J1587 data protocol, while newer systems rely on SAE J1939 over CAN bus. Bridging these two standards is essential when retrofitting dashboards, ECUs, or fleet monitoring devices. Fortunately, [...]

Understanding SAE J1939: A Comprehensive Guide to Monitoring, Simulation, and Development

In the realm of heavy-duty vehicles and industrial equipment, communication between electronic control units (ECUs) is essential. To achieve this, standardized protocols are used to ensure that data is transmitted accurately and efficiently. Among these standards, SAE J1939 stands out as a dominant communication protocol, particularly in sectors like commercial trucks, agricultural machinery, and construction [...]

Farmers Are Hacking Their Tractors Because of a Right to Repair Ban

For decades, American farmers have been at the mercy of agricultural equipment manufacturers, who have locked down their tractors with proprietary software, restricting repair options and forcing owners to seek expensive, manufacturer-approved service providers. In response, a growing number of farmers are resorting to hacking their own tractors, using underground software tools and firmware modifications [...]

SAE J1939 Technology for Agricultural Applications

The rapid advancement of technology in the agricultural sector has led to the integration of sophisticated systems to enhance efficiency, productivity, and sustainability. One such innovation is the use of the SAE J1939 protocol, a communication standard widely utilized in the field of commercial vehicles and machinery. In agricultural applications, this protocol plays a pivotal [...]

Understanding SAE J1939 and Telematics

SAE J1939 is a high-level communications protocol standard widely used in the commercial vehicle industry. Developed by the Society of Automotive Engineers (SAE), it is primarily utilized for communication and diagnostics among vehicle components and systems, including engines, transmissions, and braking systems. When integrated with telematics, SAE J1939 unlocks new possibilities for vehicle monitoring, diagnostics, [...]

Copperhill Technologies and Their J1939 Gateways

Copperhill Technologies is a company known for providing high-quality, reliable networking solutions for industrial and transportation applications. Among its range of offerings, their J1939 gateways stand out as key components for connecting devices that use the SAE J1939 protocol, a standard that is integral to modern heavy-duty vehicles and industrial machinery.Understanding SAE J1939 The SAE J1939 [...]

JCOM1939 Monitor Software - A Critical SAE J1939 Diagnostic and Analysis Tool

The JCOM1939 Monitor Software is a specialized tool designed to interface with and monitor data on the SAE J1939 communication network. SAE J1939 is a standardized protocol commonly used in heavy-duty vehicles, agriculture equipment, and industrial machinery for onboard diagnostics and data communication. This essay explores the features, applications, and significance of JCOM1939 Monitor Software in [...]

Improvements to our JCOM1939 Monitor & Simulation Software for Windows

Our SAE J1939 gateways are steadily gaining popularity, so we developed a dedicated website that focuses on the associated JCOM1939 Monitor Software for Windows. Since July of this year, we have added new features, some small and some significant improvements. With version 3.50.00, we have ceased support for older gateways, specifically those sold before 2022. The processors in [...]

Loading... Please wait...

Loading... Please wait...