Blog

Recent Posts

Understanding SAE J1939 and Telematics

Posted by on

SAE J1939 is a high-level communications protocol standard widely used in the commercial vehicle industry. Developed by the Society of Automotive Engineers (SAE), it is primarily utilized for communication and diagnostics among vehicle components and systems, including engines, transmissions, and braking systems. When integrated with telematics, SAE J1939 unlocks new possibilities for vehicle monitoring, diagnostics, and fleet management.

SAE J1939 is a high-level communications protocol standard widely used in the commercial vehicle industry. Developed by the Society of Automotive Engineers (SAE), it is primarily utilized for communication and diagnostics among vehicle components and systems, including engines, transmissions, and braking systems. When integrated with telematics, SAE J1939 unlocks new possibilities for vehicle monitoring, diagnostics, and fleet management.

The SAE J1939 Protocol

SAE J1939 is based on the Controller Area Network (CAN) protocol and operates on a robust, multi-master, and message-oriented framework. It defines a structured methodology for transmitting data in vehicular networks, ensuring compatibility and interoperability between various Electronic Control Units (ECUs). The protocol specifies:

- Parameter Group Numbers (PGNs): These identify specific data or messages, such as engine speed, fuel consumption, or fault codes.

- Data Length Codes (DLCs): These indicate the size of the data payload.

- Source Addresses (SAs): These identify the origin of the data message.

- Broadcast and Addressable Communication: Messages can be sent to all nodes (broadcast) or a specific device (point-to-point).

With its real-time capabilities, SAE J1939 is a cornerstone for diagnostics and vehicle data acquisition in heavy-duty and off-road applications.

What is Telematics?

Telematics is the intersection of telecommunications and informatics, enabling the collection, transmission, and analysis of data from vehicles. Telematics systems use wireless communication technologies, GPS, and cloud-based analytics to provide actionable insights. Common features of telematics include:

- Vehicle Tracking: Real-time location monitoring using GPS.

- Fleet Management: Optimizing routes, fuel usage, and maintenance schedules.

- Remote Diagnostics: Accessing vehicle performance data and identifying issues before they escalate.

- Driver Behavior Analysis: Monitoring speed, braking patterns, and other driving habits to improve safety.

The Integration of SAE J1939 and Telematics

The combination of SAE J1939 and telematics creates a powerful platform for enhanced vehicle management. By leveraging the standardized communication framework of SAE J1939, telematics systems can extract and transmit detailed vehicle data to centralized platforms for analysis and decision-making. Key benefits include:

- Enhanced Diagnostics: Telematics systems can decode fault codes and performance metrics from J1939 messages, enabling predictive maintenance and minimizing downtime.

- Improved Fleet Efficiency: Real-time data on fuel consumption and engine performance allows fleet managers to optimize operations.

- Regulatory Compliance: Telematics systems, using J1939 data, can ensure compliance with emissions standards and electronic logging requirements.

- Safety Monitoring: Integration with J1939 data streams provides insights into critical safety systems like braking performance and stability controls.

Use Cases in Industry

SAE J1939 and telematics find applications across various industries:

- Trucking and Logistics: Monitoring fuel efficiency, ensuring regulatory compliance, and optimizing routes.

- Construction Equipment: Real-time tracking of machinery usage and performance.

- Agriculture: Precision farming with advanced monitoring of tractors and harvesters.

- Public Transportation: Enhancing fleet safety, scheduling, and maintenance.

Challenges and Future Directions

While the integration of SAE J1939 and telematics offers substantial advantages, it comes with challenges:

- Data Security: Ensuring the security of transmitted data to prevent unauthorized access or cyberattacks.

- Complexity in Implementation: Standardizing and integrating telematics systems across diverse vehicle types and manufacturers.

- Scalability: Managing the growing volume of data from expanding fleets.

Future developments aim to address these challenges by improving encryption protocols, enhancing interoperability standards, and leveraging artificial intelligence for predictive analytics.

Conclusion

SAE J1939 and telematics represent the convergence of automotive engineering and modern data technologies. Their integration not only enhances vehicle performance and fleet management but also paves the way for smarter, more connected transportation systems. As advancements in telematics and communication protocols continue, the potential for innovation in the automotive and transportation sectors remains vast.

SAE J1939 Starter Kit and Network Simulator

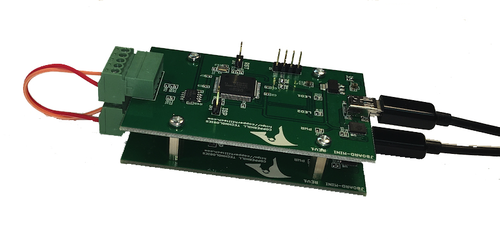

Our JCOM.J1939 Starter Kit and Network Simulator was designed to allow experienced engineers and beginners to experiment with SAE J1939 data communication without needing to connect to a real-world J1939 network, i.e., a diesel engine.

To establish a network, you need at least two nodes. This applies especially to CAN/J1939, where the CAN controller will shut down after transmitting data without receiving a response. Therefore, our jCOM.J1939 Starter Kit and Network Simulator consist of two J1939 nodes: our jCOM.J1939.USB, an SAE J1939 ECU Simulator Board with USB Port. More Information...

Copperhill Technologies and Their J1939 Gateways

Copperhill Technologies is a company known for providing high-quality, reliable networking solutions for industrial and transportation applications. Among its range of offerings, their J1939 gateways stand out as key components for connecting devices that use the SAE J1939 protocol, a standard that is integral to modern heavy-duty vehicles and industrial machinery.Understanding SAE J1939 The SAE J1939 [...]

JCOM1939 Monitor Software - A Critical SAE J1939 Diagnostic and Analysis Tool

The JCOM1939 Monitor Software is a specialized tool designed to interface with and monitor data on the SAE J1939 communication network. SAE J1939 is a standardized protocol commonly used in heavy-duty vehicles, agriculture equipment, and industrial machinery for onboard diagnostics and data communication. This essay explores the features, applications, and significance of JCOM1939 Monitor Software in [...]

Mining Machinery Telematics - Fuel Monitoring, Diagnostics

Powerful engines of mining machinery consume large amounts of fuel and are subjected to high loads and wear, directly affecting fuel expenses, maintenance, and repairs. Technoton's solution for mining machinery allows monitoring of fuel consumption and engine runtime in different load modes. This helps to understand machine usage and assess wear and tear for timely maintenance [...]

Know OBD2 Before You Start That Development Project

We at Copperhill Technologies offer a variety of CAN (Controller Area Network) devices for developing automotive and industrial embedded systems. In that capacity, we receive frequent inquiries regarding OBD2 (Onboard Diagnostics). OBD2, or Onboard Diagnostics Second Generation, is a vehicle diagnosis system found in modern cars and trucks. The OBD2 system collects data from sensors and [...]

Contactless CAN Bus, SAE J1939, OBD-II, SAE J1708 Reader

CAN (J1939) and J1708 networks transport multiple valuable information for telematics of vehicles and stationary objects, such as engine parameters, ABS, EPS, diagnostic codes (DTC), and much more. Crocodile contactless readers are used in telematics systems to gather data from digital buses without breaking the insulation of wires and electrical contacts and without sending active requests [...]

Selection Criteria and Requirements for a Telematics Gateway

The March 2023 issue of the CAN Newsletter, a CiA (CAN-in-Automation) online publication, posted an article on the selection criteria and requirements for a Telematics gateway. With cars evolving towards network technologies, OEMs (Original Equipment Manufacturers) require telematics solutions that boost seamless communication within and outside the vehicle. The device should be cloud-enabled, connectable to servers for real-time [...]

Telematics Gateway for Real-Time SAE J1939 or ISOBUS Data Monitoring

The CANUp telematics gateway by Technoton measures the operational parameters of vehicles and equipment and reports their performance. The core feature of the CANUp gateway includes the utilization of edge/fog computing methods, which detect 10,000+ possible parameters of vehicle or equipment operation and send generated operation reports to a web-based telematics server and directly to a user via [...]

Data Acquisition from Heavy Duty Vehicles Using SAE J1939 CAN Bus

Modern vehicles have electronic control units (ECUs) to control various subsystems such as the engine, brakes, steering, air conditioning, and infotainment. These ECUs (or ‘controllers’) are networked to convey information and output measured and calculated data to each other.This in-vehicle network is a data goldmine for improved maintenance, measuring vehicle performance and its subsystems, fleet [...]

SAE J1708 To SAE J1939 Gateway for Vehicle Telematics and Fleet Management

The MasterCAN V-Gate module reads messages from an SAE J1587 and SAE J1939 network, filters and merges the data into single SAE J1939 messages, and transfers the processed data via the output CAN Bus interface. The converter is suitable for vehicles and machinery equipped with SAE J1708 (SAE J1587) networks. The device input signals may be:PGNs (Parameter Group Numbers) according [...]

Loading... Please wait...

Loading... Please wait...