Blog

Recent Posts

Embedded Systems Development for NMEA 2000

Posted by on

Embedded systems development for the NMEA 2000 (National Marine Electronics Association) protocol presents unique challenges and opportunities in the field of marine electronics. NMEA 2000 is a standardized communication protocol designed to enable robust and reliable data exchange among marine instruments and devices. This essay explores the fundamental aspects of developing embedded systems for NMEA 2000, including its architecture, design considerations, challenges, and applications.

Embedded systems development for the NMEA 2000 (National Marine Electronics Association) protocol presents unique challenges and opportunities in the field of marine electronics. NMEA 2000 is a standardized communication protocol designed to enable robust and reliable data exchange among marine instruments and devices. This essay explores the fundamental aspects of developing embedded systems for NMEA 2000, including its architecture, design considerations, challenges, and applications.

Overview of NMEA 2000

NMEA 2000 is a Controller Area Network (CAN)-based protocol optimized for the marine environment. It supports high-speed data transfer and ensures interoperability among various devices, such as GPS receivers, autopilots, depth sounders, and engine monitors. The protocol defines standardized message formats called Parameter Group Numbers (PGNs), which encapsulate specific types of data.

NMEA 2000's architecture relies on a bus topology, where multiple nodes connect to a single backbone cable. This simplifies wiring and reduces the weight of cabling compared to older systems like NMEA 0183. With its 250 kbps data rate and multi-transmitter capability, NMEA 2000 provides a robust framework for integrating a wide range of marine devices.

Key Components of Embedded Systems for NMEA 2000

- Microcontrollers and Processors: At the heart of any embedded system is the microcontroller, which manages communication, processing, and control. NMEA 2000-compatible systems often use microcontrollers with built-in CAN controllers, such as the STM32 or Microchip PIC series.

- CAN Transceiver: A CAN transceiver translates signals between the CAN bus and the microcontroller. It ensures proper electrical signaling and robust communication over the NMEA 2000 network.

- Firmware: The firmware implements the NMEA 2000 protocol stack, including CAN message handling, PGN parsing, and data exchange logic. It ensures compatibility with the protocol’s specifications.

- Connectors and Cabling: NMEA 2000 requires specific connectors and cabling to meet marine standards for reliability and durability under harsh conditions.

Design Considerations

- Compliance with Standards: Developing NMEA 2000 devices mandates strict adherence to NMEA’s protocol specifications, including electrical, mechanical, and software requirements.

- Power Efficiency: Embedded systems in marine environments often operate on limited power sources. Efficient power management is crucial to ensure device reliability and longevity.

- Environmental Durability: Marine systems must withstand extreme conditions, including high humidity, saltwater exposure, and temperature fluctuations. Hardware design should incorporate waterproofing, corrosion resistance, and rugged enclosures.

- Interoperability: NMEA 2000 aims to enable seamless communication between devices from different manufacturers. Testing for compatibility is essential to ensure proper functionality within diverse system configurations.

- Real-Time Performance: Marine applications demand real-time data processing for critical functions such as navigation and engine monitoring. Embedded systems must prioritize low latency and high reliability.

Challenges in NMEA 2000 Development

- Licensing and Certification: NMEA 2000 development requires certification and licensing from the National Marine Electronics Association, which involves rigorous testing and compliance checks.

- Complex Protocol Implementation: Implementing the NMEA 2000 stack, including PGN handling and network management, requires a deep understanding of the protocol.

- Debugging and Diagnostics: Diagnosing issues on a CAN-based network can be challenging due to its distributed nature. Developers often rely on specialized tools like CAN analyzers and protocol simulators.

- Resource Constraints: Embedded systems operate under strict resource constraints, including limited memory and processing power, necessitating efficient code optimization.

Applications of NMEA 2000 Embedded Systems

- Navigation Systems: GPS receivers and chartplotters use NMEA 2000 to share location and route data with other onboard devices.

- Engine Monitoring: NMEA 2000 enables real-time monitoring of engine parameters such as RPM, temperature, and fuel consumption, facilitating predictive maintenance.

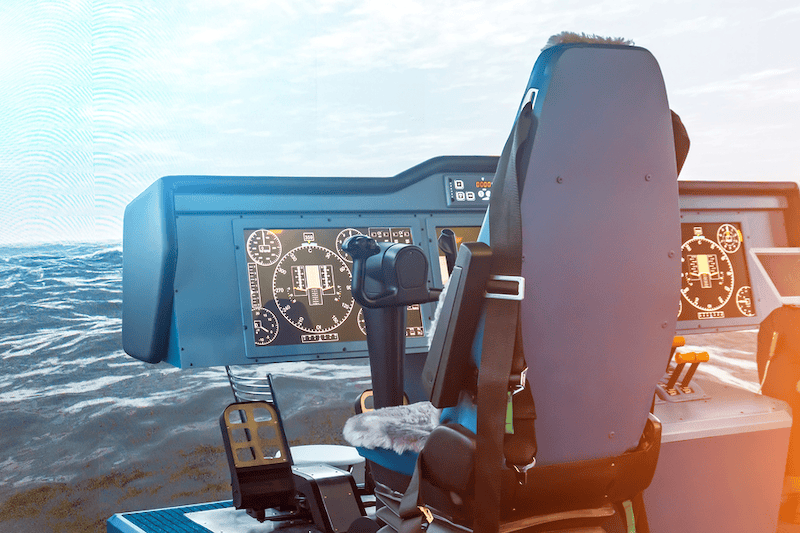

- Autopilot Systems: Autopilot devices use NMEA 2000 to receive heading and navigation data, enabling precise vessel control.

- Environmental Sensors: Weather stations and depth sounders use the protocol to provide critical data for safe navigation and decision-making.

- Entertainment and Lighting: NMEA 2000 integration extends to non-critical systems, such as audio-visual equipment and lighting, enhancing onboard comfort and convenience.

Future Prospects

As marine technology continues to evolve, the role of NMEA 2000 in embedded systems development will expand. Emerging trends such as the Internet of Things (IoT) and machine learning offer opportunities for enhancing data analytics, automation, and remote monitoring in marine systems. Furthermore, advancements in hardware and software tools will simplify the development process, making NMEA 2000 accessible to a broader range of developers.

In conclusion, embedded systems development for NMEA 2000 is a dynamic and technically demanding field. By addressing its unique challenges and leveraging its robust framework, developers can create innovative solutions that enhance the safety, efficiency, and enjoyment of marine activities.

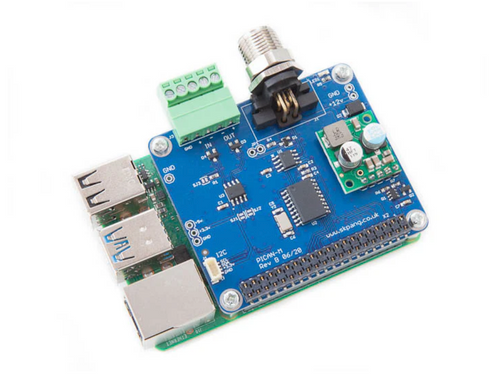

PICAN-M - NMEA 0183 & NMEA 2000 HAT For Raspberry Pi

PICAN-M - NMEA 0183 & NMEA 2000 HAT For Raspberry Pi

The PICAN-M (M = Marine) is a Raspberry Pi HAT with NMEA 0183 and NMEA 2000 connections. The NMEA 0183 (RS422) port is accessible via a 5-way screw terminal.

The NMEA 2000 port is accessible via a Micro-C connector.

Please be aware that this board cannot be powered via the NMEA 2000 connection because it lacks an onboard power supply. However, a version with a power supply (SMPS) is available.

JCOM1939 Monitor Software - A Critical SAE J1939 Diagnostic and Analysis Tool

The JCOM1939 Monitor Software is a specialized tool designed to interface with and monitor data on the SAE J1939 communication network. SAE J1939 is a standardized protocol commonly used in heavy-duty vehicles, agriculture equipment, and industrial machinery for onboard diagnostics and data communication. This essay explores the features, applications, and significance of JCOM1939 Monitor Software in [...]

Improvements to our JCOM1939 Monitor & Simulation Software for Windows

Our SAE J1939 gateways are steadily gaining popularity, so we developed a dedicated website that focuses on the associated JCOM1939 Monitor Software for Windows. Since July of this year, we have added new features, some small and some significant improvements. With version 3.50.00, we have ceased support for older gateways, specifically those sold before 2022. The processors in [...]

Diesel Diagnostic Scan Tool for J1587/J1708, J1939 Trucks

The KZYEE KC601 scanner module is the newest portable heavy-duty vehicle code reader. It can quickly and efficiently read DTCs in the truck's electrical control system, diagnose the fault location, and find the cause of the fault. It is beneficial for all auto repair shops to read and clear fault codes and read live data. The scanner [...]

SAE J1939 and OBD2 Heavy Duty Truck Scanner and Diagnostics

DPF Force Regen & Reset for Cummins Caterpillar Engine -- Reset and clean your DPF professionally, quickly, and efficiently to ensure your engine runs smoothly and meets emissions standards. This all-in-one solution saves you money on maintenance costs. The Inspection Record feature records all DPF inspections to help track and manage maintenance schedules. Full System Diesel [...]

Turn Your Smartphone into a Heavy-Duty Diagnostics Tool

Turn your smartphone into a user-friendly HD diagnostic tool. Download and sync via Bluetooth to the free Diesel Decoder smartphone app to view vital diagnostic and trip data. When your rig throws a fault code, the Diesel Decoder is your reliable companion. It removes the guesswork, guiding you to either clear the codes and continue your journey [...]

Display for Off-Road Vehicle Engines with J1939 interface

The EngineMonitorPlus is a display and control device with a CAN Bus interface designed specifically for use in off-road vehicle engines. It supports the most common messages (PGN, Parameter Group Number) of the SAE J1939 standard. Furthermore, it provides a simple configuration of displayed parameters, errors (DM1), and service messages, allowing the user to configure and [...]

Diesel Engine Fluid (DEF) Sensor Simulator - Background Info

Before Reading, Please Consider! The DEF Sensor Simulator is not a ready-made product. It was developed by a group of automotive engineers as a concept to bypass faulty DEF sensors. It consists of a list of components with an associated control code, and you will need to assemble the simulator yourself. These engineers selected a component offered [...]

SAE J1939 Data Traffic Generator For Diesel Engine Network Simulation

I am writing this post to respond to multiple inquiries from newcomers to the SAE J1939 technology. Most questions are like, "Can your device simulate any PGN, for instance, engine speed in rpm?" or "Can your device simulate a 2014 Tonka Flex diesel engine?" The short answer is yes, but things are a bit more [...]

Vehicle Computer Architectures Help Improving Diesel Engine Performance And Lifetime Costs

Engineers are leaving no stone unturned in their unceasing drive to improve fuel economy, leveraging electronics, monitoring airflow, and using data from outside the vehicle. Computer architectures are being revised to simplify controls and decrease sensor counts, helping keep costs in line. Computers continuously monitor and control the engine, transmission, after-treatment systems, and more. Powerful devices [...]

Loading... Please wait...

Loading... Please wait...