Blog

Recent Posts

CANFDuino: Upgrading the Hardware to 24 VDC Power Supply

Posted by on

Today, we are addressing a frequently asked question since the product's launch: 'Is it possible to power CANFDuino off of 12 or 24 V power?'. Our previous response, 'Yes, using the prototyping space to add a regulator', while accurate, may not have been as helpful as we intended. To provide a more practical solution, we have prepared a straightforward, step-by-step guide that will walk you through the modification needed to power the CANFDuino off of 12-24 V without relying on the USB connection as the primary power source.

A voltage regulator, a key component in our CANFDuino modification, is a device that maintains a constant voltage level. It does this by adjusting the current flow in the circuit in response to changes in voltage, and in simple terms, can be thought of as a 'voltage converter.' Voltage regulators can be either linear or switching devices, where switching devices are typically more efficient but may require more components, and linear devices are simpler but less efficient, as they require efficient heat dissipation when running under heavy load.

To simplify things, we will utilize a linear regulator to convert our 12-24 V input into a steady 5 V power source for our CANFDuino. We have chosen the LM7805 regulator for this task due to its long-standing reliability, affordability, and availability in various packaging options.

Note: The following modification worked for us based on our specific parts and setup. Your setup may differ, so there is a risk of failure, including potentially damaging the processor, when making any modifications.

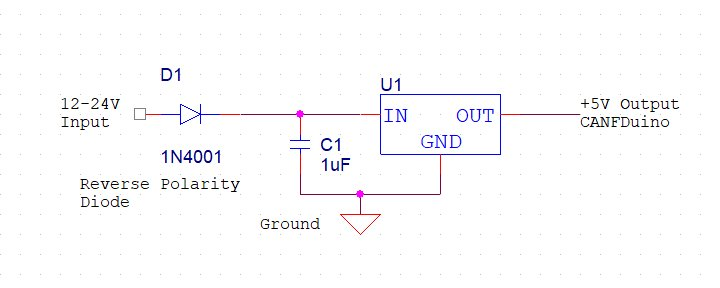

Step 1: Design Circuit

The LM7805 regulator typically requires only 1-2 additional components. These are usually input and output capacitors, stabilizing the incoming voltage and reducing any high-frequency interference that could affect the semiconductors relying on the 5V power supply.

The diagram above displays the circuit to be integrated into the CANFDuino. It includes a regulator, an input capacitor, and a blocking diode. The blocking diode is crucial as it safeguards the board from damage caused by reverse polarity. It prevents any harm from occurring if the black and red wires are unintentionally switched. We have all made this mistake at some point, so it's valuable information to include. We have decided not to include an output capacitor since the CANFDuino already has one on the 5V input side of the built-in 3.3V regulator.

Step 2: Buy & Build

Let's begin with a simple step: Visit Mouser and select the components that suit your needs and comfortably fit into your prototyping space. The CANFDuino supports SMT and through-hole components, so we used a combination of both for this circuit, as these components were available.

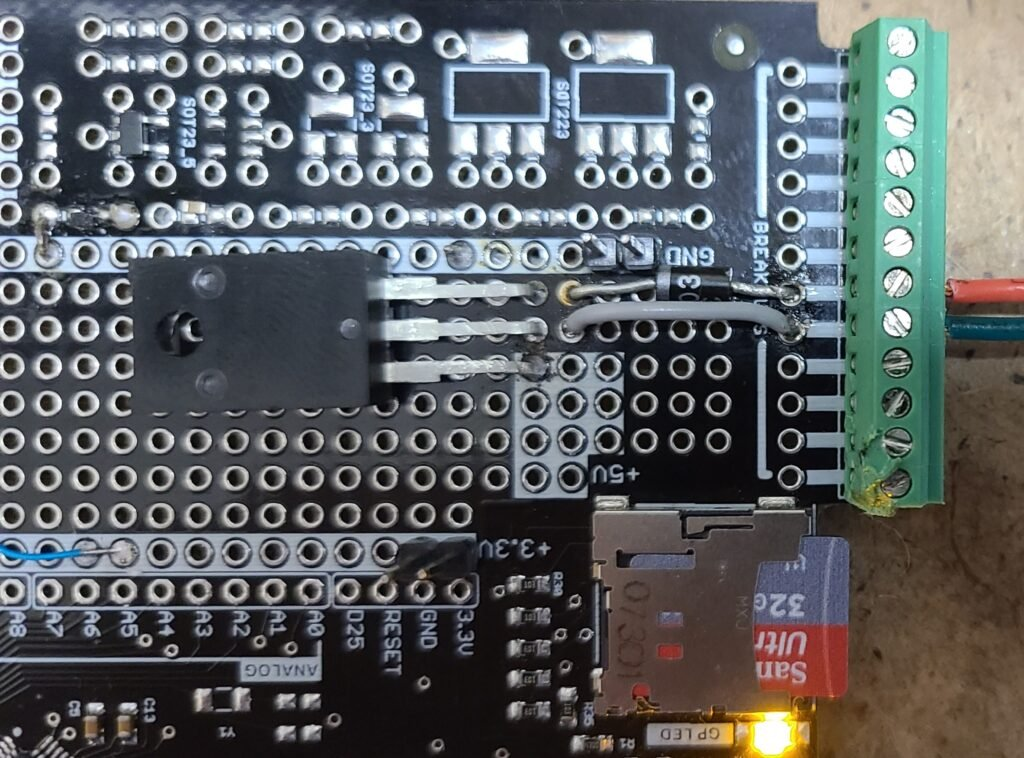

When soldering parts onto the CANFDuino, it's important to be careful. Do not solder the regulator output to the 5 V area of the CANFDuino until you have built and tested the circuit. It's best to build and test the circuit separately from the rest of the CANFDuino to avoid any damage. Once the circuit works properly, you can connect to the CANFDuino’s 5 V area. This is recommended for all modifications.

The image above shows our fully assembled mod after testing and connecting to a 5V power source. In the photo, we use breakout connections to the terminal blocks for easier wiring to our 12-24V input (red for positive input, green for negative input). Additionally, you'll notice a small capacitor on the SMT pads with wires running underneath. We've also flipped the regulator for easier mounting and soldering, which changes the orientation of the input and output pins from the diagram.

Step 3: Test Circuit

After soldering all components in place and making the power connections to the terminal block, it’s time to test. Here's how: Connect your 12-24 V source to the terminal block wiring. Then, using a DMM, check the output terminal pin; it should read 5 V. If you have good output from the regulator, power down the circuit and solder it to the 5 V area. If you do not measure 5 V, review your circuit design, regulator pinout, and components, and check the integrity of your solder connections. Once corrected, try the test again until you succeed.

Step 4: Wire and Power On

After soldering the regulator output to the 5V section, remove the boot jumper (if installed) and switch on the 12-24V power. You should notice the orange GPLED blinking, indicating the bootloader is entered. Now, you can power your CANFDuino permanently from the 12V input and connect USB whenever necessary to program the unit or monitor bus traffic. Additionally, you can combine this modification with our Bluetooth upgrade to keep the CANFDuino connected to a vehicle and establish a wireless connection.

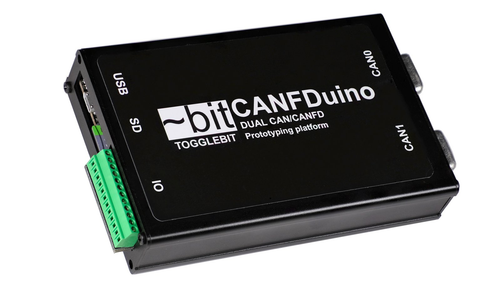

CANFDuino - Dual CAN/CANFD Prototyping Platform

The CANFDuino is a fully-equipped embedded system designed for real-world applications. It integrates essential features such as dual CAN/CANFD ports, an SD card slot, and numerous analog and digital I/O. In addition, it includes an onboard prototyping shield for SMT and through-hole components, a sturdy aluminum enclosure, and durable connectors.

The CANFDuino supports CANFD, the latest version of the CAN Bus standard, which accommodates speeds of up to 5 Mbps. It has two native ports with DB9 connectors in an enclosure, ready to be mounted on your vehicle or installed in your autonomous project. This platform suits tinkerers, hackers, and industry professionals seeking an off-the-shelf, open-source CAN Bus solution that requires minimal or no hardware assembly.

Dual-Channel Linear Actuator Control Module with ESP32

As part of a customer project, I, with the help of a capable hardware designer, developed an embedded system to control two linear actuators, specifically the Thomson Electrac HD model with SAE J1939 interface. The Electrac series of actuators supports two higher-layer protocols (HLP) based on Controller Area Network (CAN): CANopen, and SAE J1939. CANopen is [...]

Diesel Engine Fluid (DEF) Sensor Simulator - Background Info

Before Reading, Please Consider! The DEF Sensor Simulator is not a ready-made product. It was developed by a group of automotive engineers as a concept to bypass faulty DEF sensors. It consists of a list of components with an associated control code, and you will need to assemble the simulator yourself. These engineers selected a component offered [...]

Programming Electrac Linear Actuator - ACM, AFM Data Frames

This post represents an excerpt of Thomson Electrac HD Linear Actuator Motion Control per CAN Bus. The application note is available in eBook and Kindle format, and it includes a free downloadable source code. More Information... In this post, I am explaining the Actuator Control Message (ACM) and Actuator Feedback Message (AFM).Thomson Electrac Linear Actuator - ACM Design The [...]

Thomson Electrak Linear Actuator with SAE J1939 Interface for Railway and Industrial Applications

For many years I maintained the view that the SAE J1939 protocol, specifically its advanced network management capabilities, provides many great features to support any industrial application. SAE J1939 is an ingeniously designed protocol with very little protocol overhead, requiring only a minimal memory footprint that benefits the use of small embedded systems. I am now [...]

Application Note: Transmitting Analog Signals Using the SAE J1939 Protocol

This post is part of our series on Utilizing SAE J1939 as a Higher-Layer Protocol for Industrial Automation. In short, the application I had in mind was to read an analog signal per one SAE J1939 node and transmit the data to another J1939 node where it controls the blinking frequency of an LED. This project is based [...]

Arduino-Due-Based SAE J1939 Programming Kit - Quick Start Reference

Unleash the power of the Arduino Due with ARM Cortex-M3 processor to develop and test your SAE J1939 application, may it be an SAE J1939 to USB protocol converter, an SAE J1939 Bridge, an SAE J1939 data monitor, and many more. The SAE J1939 Programming Kit comes with many programming samples, including a full-blown SAE J1939 [...]

A Simple SAE J1939 to USB Gateway with the Arduino Uno, Mega 2560, Due, Teensy, ESP32

The following is an excerpt from SAE J1939 ECU Programming & Vehicle Bus Simulation with Arduino by Wilfried VossI deem it necessary to clarify the definition of “SAE J1939 to USB Gateway” because there are several variants of gateway applications.If you browse through the Internet in search for SAE J1939 gateways, you will primarily find CAN [...]

CAN Bus And SAE J1939 Prototyping With The Arduino Due ARM Cortex M3 Processor

Whenever it comes to building rapid prototypes for new CAN Bus or SAE J1939 applications, my first choice is regularly the Arduino Due, a microcontroller board based on the Atmel SAM3X8E ARM Cortex-M3 CPU.In general, the Arduino platform couples an easy-to-use programming environment (IDE) with a vast number of hardware extensions (shields). While I do appreciate programming [...]

CAN Bus Prototyping With Arduino Uno - Prototyping Hardware

This post is part of a series about Controller Area Network (CAN Bus) Prototyping With the Arduino Uno. As I had mentioned earlier, it is assumed that you have some basic knowledge of the Arduino, Arduino Sketches, and Arduino Shields. I will nevertheless take the opportunity of mentioning the prototyping hardware and its variants. It is important to know that the [...]

Loading... Please wait...

Loading... Please wait...