Recent Posts

Unlocking Vehicle Intelligence: A Practical Guide to CAN and LIN Bus Networks

Posted by on

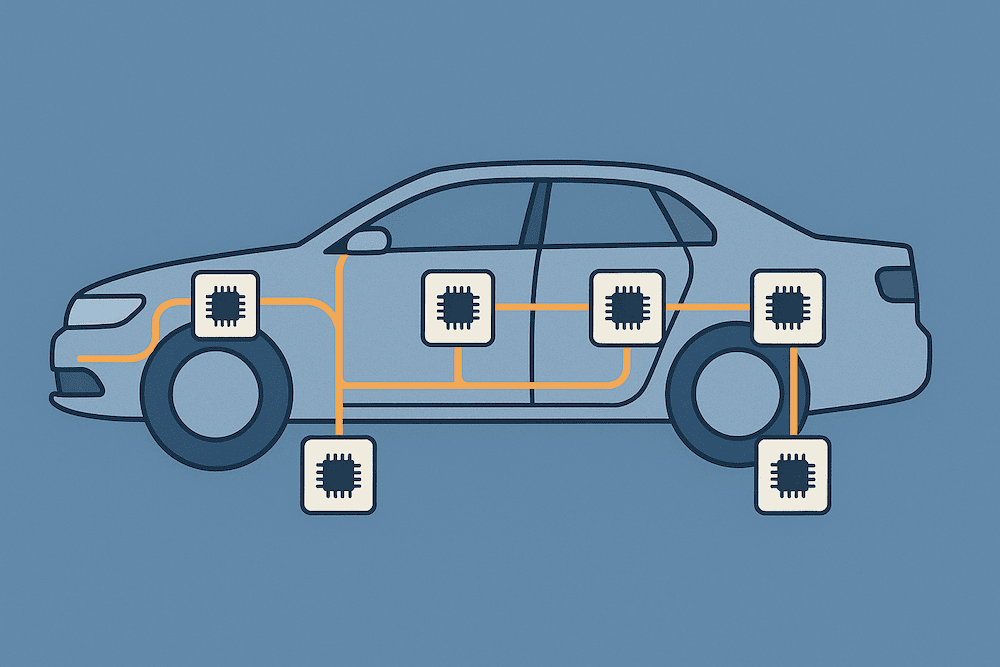

Modern vehicles contain dozens of electronic control units (ECUs) that must communicate reliably to coordinate engine, transmission, braking, body functions, and more. Two key networking technologies enabling this in-car communication are the Controller Area Network (CAN) and the Local Interconnect Network (LIN). CAN and LIN buses each have distinct architectures and roles: CAN is a high-speed, robust bus used for critical real-time ECU communication, whereas LIN is a simpler, low-cost serial network used for localized control of non-critical devices. This report provides an introductory overview of CAN and LIN bus systems – explaining their architecture, roles, and usefulness in automotive applications – followed by a comparison of their key differences. It also discusses the need for CAN-to-LIN gateways for integrating different subsystems in a vehicle. Finally, we present two example development boards that support both CAN and LIN interfaces and are suitable for embedded system projects.

Modern vehicles contain dozens of electronic control units (ECUs) that must communicate reliably to coordinate engine, transmission, braking, body functions, and more. Two key networking technologies enabling this in-car communication are the Controller Area Network (CAN) and the Local Interconnect Network (LIN). CAN and LIN buses each have distinct architectures and roles: CAN is a high-speed, robust bus used for critical real-time ECU communication, whereas LIN is a simpler, low-cost serial network used for localized control of non-critical devices. This report provides an introductory overview of CAN and LIN bus systems – explaining their architecture, roles, and usefulness in automotive applications – followed by a comparison of their key differences. It also discusses the need for CAN-to-LIN gateways for integrating different subsystems in a vehicle. Finally, we present two example development boards that support both CAN and LIN interfaces and are suitable for embedded system projects.

Controller Area Network (CAN)

Architecture: The Controller Area Network (CAN) is a multi-master broadcast serial bus originally developed by Bosch for automotive applications. In a CAN bus, all ECUs (nodes) connect to a common two-wire bus (a twisted pair: CAN High and CAN Low) with 120 Ω termination resistors at each end. This two-wire differential signaling makes CAN very robust against electrical noise and electromagnetic interference (EMI). There is no central controller; any ECU can transmit a message when the bus is free. If two nodes transmit at the same time, CAN uses a non-destructive arbitration mechanism based on message IDs to determine which message wins access without data collision. All nodes listen to the bus and each decides, based on the message ID, whether to process or ignore a given message. In this way, a single CAN network allows many ECUs to share data efficiently – for example, a brake ECU can broadcast data that the engine ECU and transmission ECU both receive and use.

Roles and Use in Automotives: CAN bus was designed to enable reliable real-time communication between critical vehicle systems. It has been widely adopted – virtually all modern cars use one or more CAN networks. A modern vehicle can easily have 70+ ECUs interconnected via CAN, coordinating powertrain, chassis, and safety functions. Typical uses of CAN include engine management, transmission control, anti-lock braking (ABS), airbag systems, power steering, and other systems where high-speed and reliable communication is required. The standard CAN protocol (ISO 11898) supports bit rates up to 1 Mbit/s, suitable for these real-time applications. An updated version, CAN FD (Flexible Data-rate), extends CAN’s capabilities with higher data rates (data phase up to 2–8 Mbit/s) and larger payloads (up to 64 bytes per frame) for advanced use cases.

Benefits and Features: Several features make CAN especially useful in automotive environments. First, it significantly reduces wiring complexity by letting ECUs communicate over a single shared bus instead of many point-to-point wires, thereby saving weight and cost. Second, CAN provides robust error handling: it includes error detection (CRC, form, acknowledgement and bit error checks) and fault confinement – nodes that misbehave can automatically remove themselves from the bus (“bus-off”) to preserve network integrity. Third, CAN is very reliable in noisy environments due to its differential bus – any external noise tends to affect both wires equally and is canceled out, preserving the signal. Lastly, CAN frames include an identifier-based priority mechanism; this makes CAN efficient by allowing priority messages to preempt lower-priority ones without loss (the lower priority node simply retries later). Overall, CAN’s combination of real-time performance, reliability, and fault-tolerance has made it the backbone of in-vehicle networks for powertrain and safety systems.

Local Interconnect Network (LIN)

Architecture: The Local Interconnect Network (LIN) is a simpler, lower-cost complement to CAN, intended for low-speed in-vehicle communication where cost and simplicity are paramount. A LIN bus is a single-wire serial network (plus ground reference) operating at up to about 19.2 kbps. The LIN topology is a master/slave arrangement: each LIN network (called a LIN cluster) has exactly one master node and up to 15 slave nodes. The master node controls all message scheduling on the bus, ensuring that only one message is transmitted at a time (thus no collisions occur and no arbitration is needed). Communication is deterministic and time-triggered: the master sends frame header signals and asks each slave for data in a round-robin or predefined schedule. This guarantees a bounded latency for each message. All nodes on a LIN bus interface through a UART-based LIN transceiver – LIN’s protocol is essentially a standard UART (SCI) byte frame augmented with a sync byte, identifier, and checksum for error checking. The physical layer of LIN uses automotive 12 V logic levels and is based on ISO 9141 (the K-line standard), which allows LIN to be implemented with minimal hardware (often just a transceiver chip like the MCP2004A and a microcontroller UART). For example, each LIN node typically has an internal pull-up resistor and one stronger pull-up at the master to keep the line at recessive (voltage high) state when no data is being sent.

Roles and Use in Automotives: LIN was introduced as an economical solution for networks where the performance of CAN is not needed. Because CAN controllers and transceivers add cost, using CAN for every small device (like a seat adjuster or window motor) would be overkill. LIN, by contrast, can be implemented inexpensively – it can run on a low-cost 8-bit microcontroller’s built-in UART and a simple transceiver, with no royalty or licensing fees for the protocol. Thus, LIN is used for non-critical, low-bandwidth functions especially in the vehicle body domain (comfort and convenience features). Typical LIN applications include electric window regulators, door lock actuators, power mirror controls, sunroof controllers, windshield wiper controllers, seat position motors, interior lighting, climate control panel communications, and similar systems. For instance, a car’s door module might be a LIN master that polls several LIN slave devices in the door (window motor, mirror, etc.), and that door module in turn connects to a higher-speed CAN network to communicate with the central body control unit. In general, LIN nodes handle tasks that are not time-critical. The network’s maximum speed (~20 kbps) and guaranteed latency (due to the master’s schedule) are sufficient for human interface related actions (like moving a window or blinking an indicator LED), but are too slow for powertrain or safety functions. Because LIN is a single-wire bus, it is more susceptible to EMI and noise (and does not have the built-in robustness of CAN’s differential signals). However, LIN does implement a checksum for error detection on data, and it supports low-power modes (nodes can be put to sleep and woken up via the bus) to reduce energy draw when systems are inactive. Overall, LIN trades performance for cost efficiency, making it very useful for integrating smart sensors and actuators in a cost-effective manner when high bandwidth or extreme reliability is not critical. Most modern vehicles contain multiple LIN sub-networks (often 10 or more LIN nodes in total in a car) serving various body electronics.

CAN vs. LIN: Key Differences

Both CAN and LIN are network protocols for in-vehicle communication, but they differ significantly in speed, complexity, cost, and usage. Below is a summary of the key differences between CAN and LIN:

- Data Rate: CAN supports much higher speeds than LIN. Classic CAN operates up to 1 Mbit/s, and CAN FD even higher, whereas LIN is limited to about 19.2 kbit/s (20 kbit/s max). High speed makes CAN suitable for real-time control (engine, brakes, etc.), while LIN’s low speed is acceptable for user-interface and comfort features.

- Network Complexity: CAN is a more complex protocol featuring dynamic multi-master capability and bus arbitration. Any CAN node can initiate a message at any time and the bus arbitration logic ensures one wins without collision. LIN, by contrast, is a single-master, multiple-slave network with a simplistic schedule-based communication scheme (no arbitration needed, since slaves only transmit when the master polls them). This makes LIN’s protocol logic much simpler but also less flexible (LIN cannot handle two nodes trying to talk simultaneously because only the master controls messaging). LIN’s simplicity allows it to be implemented with just a UART and some software, whereas CAN generally requires a dedicated CAN controller per node to handle the low-level protocol.

- Topology and Wiring: CAN uses a twisted pair of wires (CAN High and CAN Low) for differential signaling. The bus is typically a line topology with 120 Ω resistors at each end for termination. LIN uses a single wire plus ground, which reduces wiring cost and weight. There is usually a single 1 kΩ termination resistor (and diode) at the master node to bias the line, and small pull-up resistors in each slave node. The trade-off is that CAN’s differential bus offers better noise immunity than LIN’s single-ended bus. In terms of node counts, a CAN network can theoretically support a large number of nodes (limited by electrical load and bus length), while a LIN cluster is limited to 16 devices (1 master + up to 15 slaves) by design.

- Error Handling and Reliability: CAN includes robust error detection (CRC, bit monitoring, etc.) and error confinement (faulty nodes automatically shut off if they misbehave). It also supports message acknowledgments and retransmission of lost frames. LIN provides a basic checksum for error detection and has error signaling, but it is not as fault-tolerant as CAN. For example, LIN has no automatic retransmission – if a message is lost due to noise, it might only be sent again when the master’s schedule repeats that frame. CAN’s reliability features make it preferred for safety-critical data, whereas LIN is acceptable for non-critical data where an occasional lost message is not catastrophic.

- Cost and Node Complexity: LIN is lower cost and simpler to implement than CAN. LIN nodes do not require specialized co-processors; a cheap microcontroller with a UART interface can suffice. The LIN protocol itself is open and royalty-free. In addition, LIN’s single-wire physical layer means less wiring and cheaper connectors. CAN nodes, while not extremely expensive (thanks to widespread adoption), involve more complexity – each node needs a CAN controller (often built into microcontrollers in automotive-grade chips) and a CAN transceiver chip, and the wiring harness is more complex (twisted pair cabling, termination resistors, etc.). Overall, for any given function, a LIN implementation tends to be cheaper than a CAN implementation. This is why LIN is used in high-volume, cost-sensitive parts of the car (like door and seat modules) where the performance trade-off is acceptable.

- Typical Use Cases: CAN and LIN end up serving different domains within a vehicle. CAN is used for the high-speed, critical networks – for example, the engine control network, transmission, airbags, ABS, power steering, and often also the main body control network. These are areas where fast and reliable communication is essential. LIN, on the other hand, is used for low-speed, local networks – typically in sub-systems like door controls, seat controls, steering wheel controls, climate control panels, lighting modules, etc. For instance, the commands from the body control module to lock doors or roll down windows might be sent to a LIN master in each door, which then actuates LIN slave devices for the locks and window motors. In summary, CAN connects the vehicle’s “nervous system” for critical functions, while LIN is like a branch network for less critical but convenient features.

CAN-to-LIN Gateways and Integration

Given that modern vehicles often use a mix of CAN and LIN networks, there arises a need for CAN–LIN gateways to allow communication between different subsystems. A typical scenario is a LIN sub-network (e.g. in a car door or seat) that must exchange data with the main CAN bus of the vehicle. The LIN master node of that sub-network will often serve as a gateway to the CAN bus. In other words, one ECU might have a foot in both worlds – acting as a LIN master to some devices while also connecting to a CAN network to relay information upstream or accept commands from other CAN nodes. This gateway functionality is crucial for system integration: it ensures that data produced on a LIN bus (say, a window position sensor reading) can be communicated to the CAN bus (so that a central comfort module knows the window is open), and conversely that commands from the CAN side (like “lock all doors”) can be forwarded to the appropriate LIN bus devices.

The need for a gateway stems from the fundamental differences in the protocols. CAN and LIN are not directly compatible at the physical or data link level – they differ in voltage levels, frame format, timing, etc. Thus, you cannot simply tie a LIN wire into a CAN bus. Instead, a microcontroller or ECU must bridge them by receiving messages on one bus, possibly translating or reformatting them, and then transmitting on the other bus. Due to the different speeds and message structures, the gateway often must implement buffering and perhaps schedule LIN messages based on CAN events or vice versa. For example, if a CAN message for “headlamp on” needs to reach a LIN-connected headlamp actuator, the gateway ECU might receive the CAN frame, then queue and send the corresponding LIN frame during the next LIN bus slot for that command. The gateway may also perform data conversion (e.g. CAN uses 11-bit or 29-bit message IDs, while LIN might use 6-bit IDs for schedules) and ensure timing requirements are met for both sides.

In practice, designing a CAN-LIN gateway involves programming an embedded processor that has both a CAN controller and a LIN interface. The gateway code maps CAN messages to one or more LIN frames and vice versa, according to the needs of the vehicle’s communication matrix. Fortunately, LIN’s design anticipates this use: LIN messages are often arranged such that the LIN master (gateway) knows exactly what data to forward onto CAN. Manufacturers use gateways to maintain a separation between high-speed domains and low-speed domains, which can localize faults and reduce load on the CAN bus by offloading simple tasks to LIN. In summary, a CAN-to-LIN gateway is essential for interfacing disparate vehicle networks, enabling the CAN backbone to communicate with the various LIN sub-networks that handle local functions. This distributed approach optimizes cost and performance – high-bandwidth data stays on CAN, while LIN handles the cheap-and-cheerful tasks – with the gateway providing the necessary link so the entire car functions as one integrated system.

Embedded Development Boards Supporting CAN & LIN

For engineering students and automotive system designers, having hardware that can interface with both CAN and LIN buses is extremely useful for prototyping and testing. Below we highlight two example embedded development boards that support both CAN and LIN communication. These boards allow developers to experiment with sending/receiving CAN and LIN messages and even implement custom CAN-LIN gateway logic in a lab setting. We focus on their features and why they are well-suited for CAN/LIN development.

Teensy 4.0 CAN FD and LIN Bus Breakout Board

The Teensy 4.0 CAN FD & LIN breakout board is a microcontroller-based development board that integrates a powerful Teensy 4.0 MCU with transceivers for both CAN FD and LIN. The Teensy 4.0 module (included pre-installed) features an ARM Cortex-M7 processor running at 600 MHz, providing robust performance for real-time communication and protocol handling. Developers can program the Teensy using the familiar Arduino IDE and libraries, which makes firmware development accessible and quick.

The Teensy 4.0 CAN FD & LIN breakout board is a microcontroller-based development board that integrates a powerful Teensy 4.0 MCU with transceivers for both CAN FD and LIN. The Teensy 4.0 module (included pre-installed) features an ARM Cortex-M7 processor running at 600 MHz, providing robust performance for real-time communication and protocol handling. Developers can program the Teensy using the familiar Arduino IDE and libraries, which makes firmware development accessible and quick.

This board’s key feature is support for both Classical CAN 2.0B and CAN FD. It includes an on-board CAN FD transceiver, enabling CAN operation at standard speeds and CAN FD operation with data payloads up to 64 bytes. This means the board can be used with modern CAN FD networks (common in newer vehicles for high-speed data needs) while remaining backward compatible with classic CAN. On the LIN side, the board uses an integrated Microchip MCP2004A LIN transceiver, which supports LIN 2.x protocols at communication speeds up to 20 kbps. The LIN interface can be configured as either a LIN master or a LIN slave via a jumper setting (JP9) on the board. This is useful for testing both sides of LIN communication – for example, the board could act as a LIN master controller in one setup, or emulate a LIN slave device in another.

In addition, the Teensy 4.0 breakout board is designed with automotive-friendly features. It has an onboard 5 V regulator that can accept +12 V DC input, allowing the board (and Teensy MCU) to be powered from a vehicle battery or bench supply of 7–12 V. The power circuit includes reverse-voltage protection to prevent damage if the supply leads are accidentally reversed, an important safeguard in automotive environments. The board also includes an optional 120 Ω termination resistor for the CAN bus (which can be enabled or disabled via jumper JP1) and built-in ESD protection on the CAN/LIN transceiver lines. These features simplify the process of connecting the board to a live vehicle network or testbench, as the necessary termination and protection are already on-board.

Overall, the Teensy 4.0 CAN FD and LIN board provides a versatile platform for developing and prototyping mixed-network applications. Its high-performance MCU can run real-time tasks like translating messages between CAN and LIN (i.e. acting as a custom gateway) and logging or processing bus data. In fact, the board is described as ideal for bridging different vehicle domains – for example, one could program it to read messages from a car’s CAN bus and output corresponding commands onto a LIN bus, enabling interoperability in a test setup. The combination of Arduino-compatible ease of use with automotive-grade capabilities (CAN FD, LIN, power conditioning) makes this board well-suited for students and engineers building hands-on projects that involve CAN and LIN communications.

PiCAN FD with LIN Bus and SMPS for Raspberry Pi

The PiCAN FD with LIN Bus board is an add-on HAT for Raspberry Pi single-board computers, providing one channel of CAN FD and one channel of LIN, along with a built-in power supply unit (SMPS) for automotive use. This board is designed by SK Pang/Copperhill to interface with the Raspberry Pi’s 40-pin header, making it a convenient tool for leveraging the Pi’s computing resources for CAN/LIN development. Because it attaches to a Raspberry Pi, it allows developers to work in a high-level environment (Linux OS, SocketCAN, Python/C programming) while interfacing with automotive networks.

The PiCAN FD with LIN Bus board is an add-on HAT for Raspberry Pi single-board computers, providing one channel of CAN FD and one channel of LIN, along with a built-in power supply unit (SMPS) for automotive use. This board is designed by SK Pang/Copperhill to interface with the Raspberry Pi’s 40-pin header, making it a convenient tool for leveraging the Pi’s computing resources for CAN/LIN development. Because it attaches to a Raspberry Pi, it allows developers to work in a high-level environment (Linux OS, SocketCAN, Python/C programming) while interfacing with automotive networks.

Features: On the CAN side, the PiCAN FD HAT uses the Microchip MCP2518FD CAN controller chip, which supports Classical CAN and CAN FD operation. The CAN transceiver on the board along with the MCP2518FD controller handle the CAN bus physical layer and protocol, and they interface with the Raspberry Pi via SPI. The CAN interface supports arbitration bit rates up to 1 Mbps and data bit rates up to 8 Mbps (for CAN FD). The board is fully integrated with Linux SocketCAN – once installed, it appears as a network interface (can0) on the Raspberry Pi, allowing developers to use standard CAN utilities or write software to send/receive CAN frames using socket APIs. An on-board 120 Ω terminator is available (and can be enabled if this board is at the end of a CAN bus). There are also status LEDs for CAN traffic indication. Overall, the CAN functionality turns a Raspberry Pi into a capable CAN/CAN-FD node or logger with minimal setup.

For the LIN bus, the PiCAN FD HAT includes a dedicated dsPIC33 microcontroller which acts as the LIN controller/translator. This microcontroller manages LIN protocol timing and framing, and it communicates with the Raspberry Pi over a UART (ttyS0) using simple ASCII text commands. In essence, the dsPIC33 presents a command interface so that a program on the Pi can instruct it to send LIN frames or can read LIN data from it. This design abstracts the low-level LIN timing so that the Raspberry Pi (which is not real-time) can still interact with LIN devices reliably. The LIN interface can operate as master or slave, selectable via a jumper, just like the Teensy board’s LIN interface. This means developers can use the HAT to simulate either a LIN master node or a LIN slave node in their setup. The firmware on the LIN’s dsPIC33 is user-upgradable (the board provides a method to update the micro’s firmware, ensuring future LIN features or fixes can be applied). An LED indicator is present for LIN bus activity as well.

One of the standout features of this PiCAN FD board is the integrated 3A Switched-Mode Power Supply (SMPS). The HAT includes a 3 amp DC-DC converter that can take an external input of about 7 V to 24 V (for example, directly from a vehicle’s 12 V battery) and regulate it to power the Raspberry Pi and the PiCAN board safely. In other words, you can power the whole Raspberry Pi system from a car’s battery using this board – a very useful feature for in-vehicle datalogging or prototyping. The SMPS provides sufficient current for the Pi and attached devices, and being an automotive-grade supply, it handles the vehicle voltage range and transients. This eliminates the need for a separate power regulator when using the Pi in a car, simplifying experimental setups. The board’s design adheres to the Raspberry Pi HAT standard (including mounting holes and EEPROM for configuration), making installation plug-and-play.

Suitability for Development: With this HAT, a Raspberry Pi can function as a bridge or data logger between CAN and LIN networks. For example, one could write a Python program on the Pi to log CAN bus data while simultaneously sending test messages to a LIN device. The board comes with software support; there is an easy-to-install SocketCAN driver for the CAN controller, and example LIN bus software (including a GUI application in Python/tkinter) is provided to help developers get started. Developers can program in high-level languages (C or Python are commonly used) on the Pi, which is great for rapid development of prototypes or data analysis scripts. This board is especially useful in scenarios where a lot of processing or user interface is needed in addition to bus communication – the Raspberry Pi can run complex software (even a full UI or database) while the PiCAN FD HAT handles the real-time CAN/LIN interfacing. Because it supports CAN FD, it is forward-looking and compatible with newer automotive networks, and its LIN capability makes it versatile for body electronics testing. Overall, the PiCAN FD with LIN Bus and SMPS HAT provides a convenient, feature-rich platform for anyone looking to experiment with or develop applications involving both CAN and LIN buses, leveraging the power of Raspberry Pi in an automotive networking context.

Loading... Please wait...

Loading... Please wait...