Blog

Recent Posts

NMEA 2000 Explained: A Practical Guide to CAN Bus Marine Networking

Posted by on

Modern marine electronics rely on NMEA 2000, a standardized CAN-based network that allows engines, sensors, displays, navigation systems, and monitoring devices to communicate over a single, shared backbone. Instead of point-to-point wiring, NMEA 2000 uses a robust two-wire CAN bus to distribute data efficiently and reliably across the vessel. While powerful and flexible, this technology often appears intimidating due to unfamiliar terminology, strict wiring rules, and a lack of clear beginner-level explanations.

Modern marine electronics rely on NMEA 2000, a standardized CAN-based network that allows engines, sensors, displays, navigation systems, and monitoring devices to communicate over a single, shared backbone. Instead of point-to-point wiring, NMEA 2000 uses a robust two-wire CAN bus to distribute data efficiently and reliably across the vessel. While powerful and flexible, this technology often appears intimidating due to unfamiliar terminology, strict wiring rules, and a lack of clear beginner-level explanations.

Many boat owners, technicians, and engineers struggle to understand how CAN Bus and NMEA 2000 systems actually work in practice. Confusing diagrams, fragmented documentation, and overly theoretical explanations make it difficult to build or troubleshoot a network with confidence. That is exactly why First Steps in CAN Bus with NMEA 2000 was written. This book provides a beginner-friendly yet technically accurate path to understanding, designing, and maintaining NMEA 2000 networks without requiring prior CAN experience.

Whether you are new to marine electronics or looking to strengthen your foundation before moving on to advanced configurations, this guide walks you through every critical concept step by step. It explains how CAN communication works, how NMEA 2000 builds on it, and how real devices share data on the network. Rather than acting as a dry reference manual, the book emphasizes practical understanding through real-world examples, clear diagrams, and straightforward explanations.

Inside the book, you will learn how to design a stable network using correct cabling and termination practices, manage power and grounding to avoid common failures, understand PGNs and data flow, and safely integrate displays, sensors, GPS units, and engine gateways. Dedicated chapters focus on troubleshooting and testing, showing how to diagnose voltage issues, communication errors, and network load problems using practical methods that reflect real installations.

Written with field-tested experience and a clear, professional voice, First Steps in CAN Bus with NMEA 2000 turns a complex marine communication standard into something practical and approachable. It gives you the knowledge and confidence to design, install, and maintain reliable NMEA 2000 networks, helping your systems perform as intended and saving time, frustration, and costly mistakes along the way. More information...

ESP32S3 NMEA2000 Device Simulator

ESP32S3 NMEA2000 Device Simulator

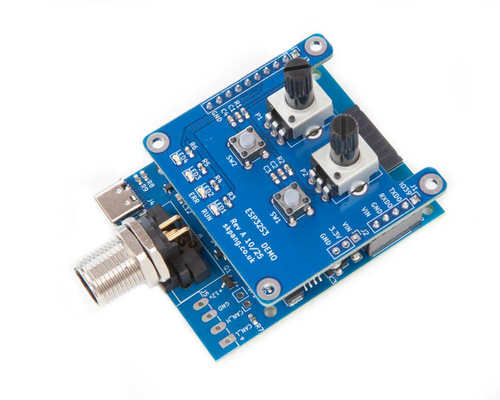

This ESP32-S3 NMEA 2000 device simulator is a two-board development and testing platform designed to generate and control NMEA 2000 traffic on a CAN-based marine network. The base board is built around an ESP32-S3 microcontroller with integrated Wi-Fi, Bluetooth LE, and an onboard CAN transceiver, providing the processing and communication core. A stacked top board adds physical user controls, including potentiometers, push buttons, and indicator LEDs, allowing developers to interactively adjust simulated values and trigger events in real time. The simulator is preconfigured to generate standard NMEA 2000 Parameter Group Numbers such as environmental data, enabling realistic sensor emulation without requiring actual marine hardware.

The device is intended for development, testing, and validation of NMEA 2000 products, gateways, and embedded applications. Its firmware is fully reprogrammable, allowing the simulated PGNs and control behavior to be adapted to custom use cases beyond the default configuration. By combining a flexible ESP32-S3 platform with intuitive hardware controls, the simulator provides a practical and efficient way to test network behavior, verify device interoperability, and accelerate development of CAN-based marine and embedded systems. More information...

Why CAN and LIN Need to Communicate in Modern Vehicles

At first glance, it may seem odd that a vehicle would use two different network technologies—CAN (Controller Area Network) and LIN (Local Interconnect Network)—and even stranger that they need to communicate with each other. After all, why not use one network everywhere and avoid the complexity? The truth is that both CAN and LIN exist because [...]

CAN Bus Programming in Python for Automotive, Industrial Automation, and Robotics

The Controller Area Network (CAN bus) is a resilient, lightweight, and efficient communication protocol originally developed by Bosch in the 1980s for in-vehicle networks. It allows multiple microcontrollers (ECUs) and devices to communicate without a central host, using a multi-master, message-oriented design. Over the decades, CAN bus has expanded beyond its automotive roots into domains [...]

Mastering CAN Bus: Essential Guide to Understanding and Troubleshooting Vehicle Networks

In today’s world of connected vehicles and industrial automation, understanding the details of networked communication protocols has become a pivotal skill for engineers and technicians alike. The book Mastering CAN Scratch: Understanding & Troubleshooting (ISBN/ASIN B0G24Z25RZ) steps into this space by offering a comprehensive, hands-on guide to the widely used Controller Area Network (CAN) bus [...]

Mastering CAN Bus: A Deep Dive into Automotive CAN Bus and In-Vehicle Networks

In an age when vehicles are less about purely mechanical linkages and increasingly about interconnected electronics and networks, the book Automotive CAN Bus and In-Vehicle Networks arrives at exactly the right moment. Graham Stoakes presents what he calls “the digital nervous system of modern vehicles” — and for technicians, students, and enthusiasts alike, this translates [...]

Comparing SAE J1939 Baud Rates: Evaluating 250k vs. 500k for Modern Vehicle Networks

For years, SAE J1939 has been synonymous with heavy-duty vehicle networking, and 250k baud has been the de facto standard. But as vehicles grow more connected and data-intensive—think emissions controls, advanced diagnostics, telematics, and electrification—the question arises: is 250k still enough? The recent discussion around adding a 500k baud rate to the J1939 standard aims to [...]

CAN Bus and SAE J1939: A Beginner’s Guide to Network Design

If you’ve ever worked with industrial machines or diesel engines, chances are you’ve heard of CAN bus and SAE J1939. These two go hand-in-hand when it comes to reliable, real-time communication between control units. Let’s break down the essentials of how these networks are designed and why they matter. What Is CAN Bus? CAN (Controller Area Network) [...]

Unlock the Future of Marine Apps with the ESP32-S3 CAN Bus Board with NMEA 2000 Connector

As the marine industry continues to embrace smart technologies, there's a growing demand for powerful, connected, and reliable embedded solutions that can handle everything from engine diagnostics to GPS data aggregation. Whether you're building a marine monitoring system, an onboard data logger, or an intelligent control unit, you need a development board that offers high [...]

Harnessing the Power of the ESP32-S3: A Look at Copperhill’s CAN FD Development Board

In the evolving landscape of IoT, industrial automation, and automotive communication, the demand for a versatile, wireless-enabled microcontroller with CAN bus capabilities has never been greater. Copperhill Technologies rises to the occasion with its latest innovation—a development board based on the ESP32-S3-WROOM-1-N8R8, engineered to support both Classical CAN and CAN FD protocols. At the heart of [...]

Unlocking Vehicle Intelligence: A Practical Guide to CAN and LIN Bus Networks

Modern vehicles contain dozens of electronic control units (ECUs) that must communicate reliably to coordinate engine, transmission, braking, body functions, and more. Two key networking technologies enabling this in-car communication are the Controller Area Network (CAN) and the Local Interconnect Network (LIN). CAN and LIN buses each have distinct architectures and roles: CAN is a [...]

Loading... Please wait...

Loading... Please wait...