Blog

Recent Posts

Why CAN and LIN Need to Communicate in Modern Vehicles

Posted by on

At first glance, it may seem odd that a vehicle would use two different network technologies—CAN (Controller Area Network) and LIN (Local Interconnect Network)—and even stranger that they need to communicate with each other. After all, why not use one network everywhere and avoid the complexity?

At first glance, it may seem odd that a vehicle would use two different network technologies—CAN (Controller Area Network) and LIN (Local Interconnect Network)—and even stranger that they need to communicate with each other. After all, why not use one network everywhere and avoid the complexity?

The truth is that both CAN and LIN exist because each serves a very different purpose, and modern vehicles demand both speed and cost efficiency. Once you see how they complement each other, the need for communication between them becomes perfectly logical.

Two Networks, Two Roles

CAN is the backbone of high-speed communication in a vehicle. It’s robust, fast, fault-tolerant, and designed for the demanding environment of engine management, braking systems, transmissions, and other areas where timing and reliability are critical. Most messages on CAN require quick delivery and high integrity—qualities that make CAN ideal for safety-related and performance-sensitive functions.

LIN, on the other hand, focuses on simplicity and cost savings. It operates at much lower speeds and uses a single wire instead of a twisted pair. LIN is often found in smaller, local subsystems such as door modules, mirror controls, seat motors, HVAC flap actuators, and steering-wheel buttons. These devices don’t need the speed or robustness of CAN, and their low-cost architecture helps keep overall vehicle costs down.

How They Communicate

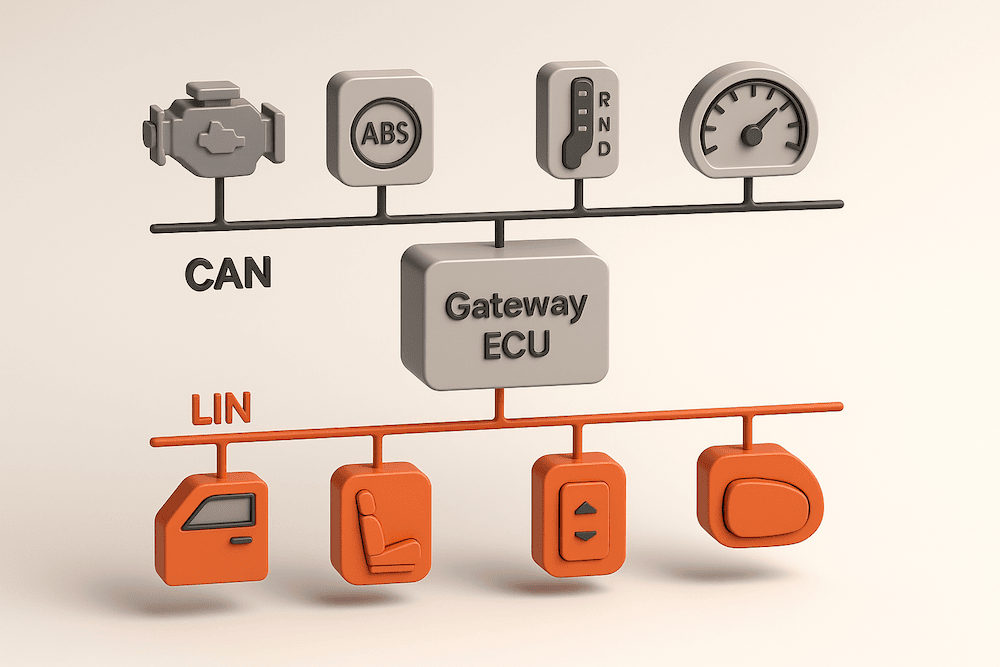

Although CAN and LIN never talk to each other directly, they are connected through gateway nodes—typically microcontrollers that contain both a CAN controller and a LIN transceiver. These gateway ECUs act as translators. They listen to the LIN bus, extract information from sensors or actuators, convert it into the appropriate CAN messages, and send it out on the higher-speed network. The process also works in reverse, allowing CAN messages to trigger actions on LIN nodes.

The ECU essentially speaks both languages and decides what data needs to move between the two domains. Without such gateways, the hundreds of small LIN devices scattered throughout a vehicle would remain isolated, unable to share their information with central control units.

Everyday Examples in a Vehicle

Communication between CAN and LIN happens constantly. Consider the window controls in a modern car. A door module might use LIN to gather information from a window motor or position sensor. That same module may then translate the data into CAN messages so the body control module can handle anti-pinch detection, global open/close functions, or alarm-system logic.

A similar pattern appears in power seats. Many of the motors inside a seat are LIN-based. Their position information must reach the CAN network so that memory functions, safety systems, and driver-profile synchronization can work properly.

Even steering-wheel buttons often connect via a tiny LIN network. When you raise the volume or answer a call, a LIN-connected switch sends the button press to a gateway, which instantly converts it into a CAN message for the infotainment system.

And in the HVAC system, flap actuators typically communicate through LIN, while the climate ECU exchanges temperature control data over CAN. The gateway stitches these pieces together.

Why Not Use CAN Everywhere?

Cost is the dominant reason. LIN is inexpensive to implement, requires simpler microcontrollers, and drastically reduces wiring complexity. A modern vehicle may contain dozens of tiny actuators and sensors—often 30, 40, or even more. If each LIN device saves even a few dollars compared to a CAN-based design, the combined savings per vehicle can be significant, especially when building hundreds of thousands of units.

A Unified Vehicle Through Mixed Networks

What appears at first to be a messy mixture of protocols is actually a carefully balanced architecture. CAN delivers the speed and reliability necessary for safety-critical systems, while LIN keeps costs under control for non-critical body electronics. Gateways allow the two worlds to function as one, ensuring that everything—from engine torque requests to window positions—can be shared across the vehicle.

In short, CAN and LIN communicate because the modern automobile demands both speed and economy. The gateway ECUs bring these two technologies together, allowing them to coexist and cooperate as part of a unified system.

ESP32S3 CAN & LIN-Bus Board

ESP32S3 CAN & LIN-Bus Board

The ESP32S3 CAN & LIN-Bus Board brings together powerful modern embedded processing with native support for two of the most widely used in-vehicle communication protocols. At its heart is the Espressif ESP32-S3 module — a dual-core Xtensa® LX7 CPU running up to 240 MHz, backed by 8 MB of QSPI flash and 8 MB of PSRAM — enabling developers to run complex, real-time tasks such as gateway logic, ECU simulation, or diagnostic routines. On the connectivity side, the board includes both a CAN transceiver and a LIN transceiver (TJA1021T), making it possible to interface directly with automotive CAN and LIN networks without needing external adapters.

Beyond wired communication, the board leverages the ESP32-S3’s integrated Wi-Fi (802.11 b/g/n) and Bluetooth 5 (LE / mesh) radios, which makes it ideal for applications such as wireless diagnostics, over-the-air updates, or mobile-app integration. For ease of use and rapid development, it offers a USB-C port for programming, built-in BOOT and RESET buttons, a status RGB LED, and an I²C header for sensor expansion. Its power circuitry accepts a wide 7–14 V input with reverse-polarity protection, so it’s suitable for real-world automotive or industrial environments. More information...

Loading... Please wait...

Loading... Please wait...