Blog

Recent Posts

Local Interconnect Network (LIN) in Automotive: A Beginner’s Guide

Posted by on

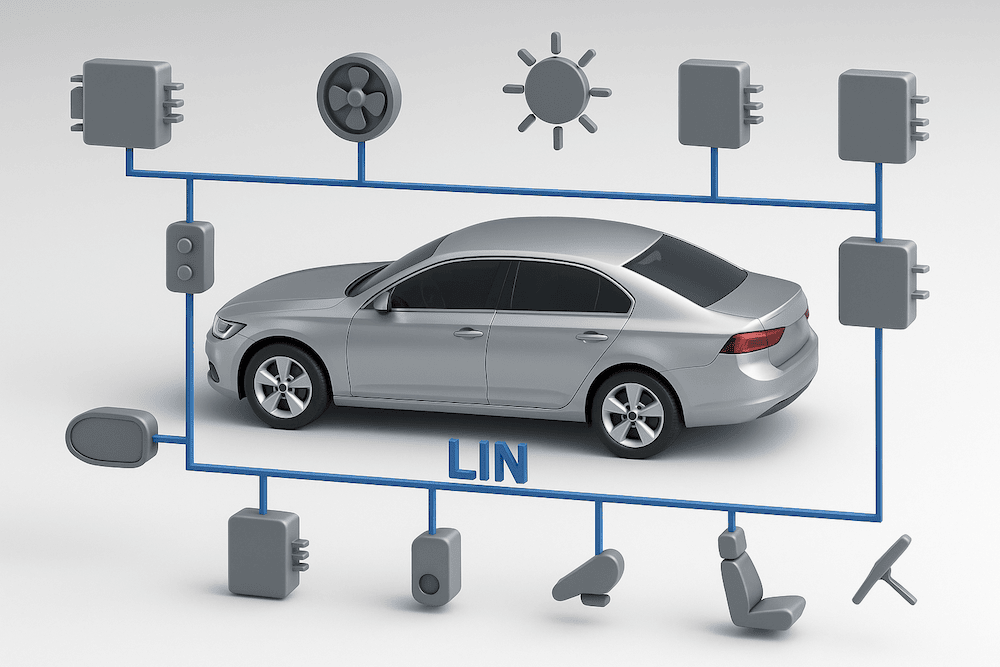

The Local Interconnect Network (LIN) is a low-cost, low-speed serial bus system used in modern vehicles to communicate between electronic components. It was introduced as a complement to the faster Controller Area Network (CAN) bus, targeting applications where high performance isn’t needed and cost is critical. LIN operates over a single wire (plus ground) at data rates up to about 19.2 kbit/s, suitable for connecting smart sensors and actuators in non-safety-critical domains. By using LIN for simple functions (like window motors or seat sensors) instead of CAN, manufacturers reduce wiring complexity and cost, as LIN nodes are typically inexpensive microcontrollers with a LIN transceiver and don’t require the sophisticated hardware of a CAN node. In practice, LIN enables expansion of in-car features (power mirrors, climate controls, etc.) without the expense of adding more CAN networks. Most modern vehicles deploy multiple LIN sub-networks (often 10 or more LIN nodes in total) for various body and comfort electronics. LIN’s simplicity and cost-efficiency have made it a de facto standard for automotive subsystem communication alongside CAN.

The Local Interconnect Network (LIN) is a low-cost, low-speed serial bus system used in modern vehicles to communicate between electronic components. It was introduced as a complement to the faster Controller Area Network (CAN) bus, targeting applications where high performance isn’t needed and cost is critical. LIN operates over a single wire (plus ground) at data rates up to about 19.2 kbit/s, suitable for connecting smart sensors and actuators in non-safety-critical domains. By using LIN for simple functions (like window motors or seat sensors) instead of CAN, manufacturers reduce wiring complexity and cost, as LIN nodes are typically inexpensive microcontrollers with a LIN transceiver and don’t require the sophisticated hardware of a CAN node. In practice, LIN enables expansion of in-car features (power mirrors, climate controls, etc.) without the expense of adding more CAN networks. Most modern vehicles deploy multiple LIN sub-networks (often 10 or more LIN nodes in total) for various body and comfort electronics. LIN’s simplicity and cost-efficiency have made it a de facto standard for automotive subsystem communication alongside CAN.

LIN Network Architecture (Master-Slave Configuration)

A LIN network (called a LIN cluster) follows a single-master/multiple-slave architecture. There is exactly one master node and up to 15 slave nodes on a LIN bus (for a maximum of 16 nodes in total). The master is typically an Electronic Control Unit (ECU) that often also connects to the higher-speed CAN bus, acting as a gateway between the LIN cluster and the rest of the vehicle network. Every other device on the LIN bus is a slave node (also an ECU with a microcontroller and LIN interface).

Master Node: The master node’s microcontroller runs a master task in addition to its normal functions. This master task is responsible for controlling all message communications on the LIN bus. It does so by broadcasting message headers according to a predefined schedule. The master is the only node allowed to initiate frames on the bus, which guarantees there are no data collisions (since slaves never transmit unless the master requests them to). The master also typically contains the stable clock source for timing and synchronizes slave nodes to this timing (more on this in the Protocol section).

Slave Nodes: Each slave node includes a microcontroller running a slave task that waits for headers from the master. Slave ECUs generally contain input/output devices – for example, a switch, sensor, or actuator – and they will respond to the master’s requests if the message ID matches one assigned to them. All LIN nodes (master and slaves) have a built-in UART/Serial Communication Interface and a LIN transceiver to interface with the single-wire bus. Because only the master schedules communication, slave nodes can use simple, low-performance microcontrollers (even 8-bit MCUs with an internal oscillator) to keep costs very low. The master-slave design simplifies the network protocol since no bus arbitration is needed – the master orchestrates all communication.

ESP32S3 CAN & LIN-Bus Board

ESP32S3 CAN & LIN-Bus Board

Powerful, compact, and built for real-world automotive and industrial networking. The ESP32S3 CAN & LIN-Bus Board combines dual-core processing with Wi-Fi, Bluetooth, and native CAN/LIN transceivers—making it the perfect platform for gateways, diagnostics, and control applications.

This board is powered by the ESP32-S3-WROOM-1-N8R8 module, featuring integrated Wi-Fi, Bluetooth 5 (LE/mesh), and an onboard CAN transceiver. A dedicated TJA1021T LIN transceiver provides full LIN-Bus support, making it ideal for automotive and industrial applications. For easy development, it includes a USB-C interface for programming, along with BOOT and RESET buttons and a multi-color RGB status LED. More information...

LIN Communication Protocol and Timing Details

Communication on a LIN bus is deterministic and time-triggered, meaning messages are sent in a fixed, periodic schedule defined by the master. Unlike CAN’s event-driven arbitration, LIN uses a schedule table where the master polls each slave in turn or at set intervals. Each entry in the schedule specifies a frame slot during which a particular message (frame) will be sent. Frame slots are often aligned to a common base time unit (e.g. 5 ms or 10 ms ticks) to ensure predictable timing. This design guarantees a known maximum latency for each message – an important feature for ensuring that even low-speed devices (like a mirror adjustment motor) respond within a bounded time.

LIN Frame Structure: All LIN messages (frames) are initiated by the master and consist of two parts: a header (from the master) and a response (from a slave or sometimes the master itself). The LIN frame format is based on standard UART serial format with one start bit and one stop bit wrapping each byte, but with some special fields added for LIN’s needs:

-

Break Field: The master begins each frame with a Break – a longer dominant (zero) signal on the bus, at least 13 bit periods long – to signal all nodes to sync up and mark the start of a new frame. This break is followed by a brief delimiter (a high voltage period) to allow nodes to prepare for the next bytes.

-

Sync Field: Next, the master transmits a Sync Byte, which is always

0x55(01010101 in binary). The pattern of alternating bits allows slave nodes to measure the current bit timing and adjust their baud rate to match the master’s clock. This is crucial because slaves often run on inexpensive RC oscillators that may not be very accurate – the sync field calibrates them for the remainder of the frame. -

Identifier Field: The master then sends an Identifier (ID) byte, which contains a 6-bit frame ID plus 2 parity bits for error checking. There are 64 possible LIN frame IDs (0–63). The parity bits help slaves detect if the ID byte was corrupted; if parity is wrong, slaves will ignore the frame. Each message ID corresponds to a specific data meaning, and each slave is configured to know which IDs it should respond to or listen to.

-

Data Field: Immediately after the header (Break+Sync+ID), the designated slave node responds with the data bytes, if that frame carries data. LIN supports frames with 2, 4, or 8 data bytes of payload (the length is typically pre-defined per message in the network). For example, an ID might be defined to always carry 2 bytes (for a sensor reading) while another ID always carries 8 bytes (perhaps for a complex status message).

-

Checksum Field: Finally, the last byte of a LIN frame is a checksum computed over the data bytes (and in newer LIN versions, also the ID). This allows receivers to detect if any bit errors occurred in the data. LIN 1.x used a classic checksum (covering only data bytes) whereas LIN 2.x introduced an enhanced checksumthat includes the ID in the calculation for improved error detection.

A complete LIN frame exchange involves the master sending the header (Break, Sync, ID) and then a slave sending back its data and checksum. Because only the addressed slave responds and all others remain silent or just listen, collisions on the bus are avoided by design. The timing of each frame is set such that even the slowest slave node can process the ID and prepare its response in time. There is a concept of “response space” (a small delay) between the header and the slave’s response, as well as optional gaps between bytes, to accommodate slaves with slower microcontrollers if needed.

Deterministic Scheduling: The master’s schedule table can contain different frame types and repetition rates. Critical or regularly updated signals use unconditional frames sent at fixed rates (e.g. a sensor value every 100 ms). LIN also provides special frame types like event-triggered frames (which allow a slave to respond only when a certain event/state change occurs, saving bus bandwidth) and sporadic frames (frames that the master sends only on demand, typically carrying infrequent data). In practice, the vast majority of traffic in a LIN bus are unconditional frames on a fixed schedule, keeping the protocol simple. If an event-triggered frame collision occurs (two slaves try to respond to the same event frame because both had an event), the master detects no valid response and can fall back to polling those events via individual frames, thereby resolving the collision in the next schedule cycle.

Bus Sleep and Wakeup: To conserve vehicle battery power, LIN networks support a sleep mode. If the master stops sending frames (or explicitly sends a Sleep Frame), slave nodes will enter a low-power sleep state after a defined timeout. When the network needs to be active again, any node (master or a wake-capable slave) can issue a wake-up signal on the bus – which is simply a dominant voltage (bus pulled low) for a minimum duration (typically 250 µs to 5 ms) followed by a pause. This wakeup pulse causes all transceivers to wake and the master will then resume its schedule by sending a Sync Break to start a new frame. Slaves that hear the wake-up will be ready to receive the next frame. In short, LIN bus nodes mostly remain quiet (and can sleep) until the master polls them, making LIN efficient in both bandwidth and power usage for intermittent activities.

Raspberry Pi Pico LIN-Bus Module

Raspberry Pi Pico LIN-Bus Module

LIN (Local Interconnect Network) is a serial network protocol used for communication between vehicle components. It is a single-wire, serial network protocol that supports communications up to 19.2 Kbit/s at a bus length of 40 meters. The need for a cheap serial network arose as the technologies and the facilities implemented in the car grew. At the same time, the CAN bus was too expensive to implement for every component in the car. European car manufacturers started using different serial communication technologies, which led to compatibility problems.

This board uses the Raspberry Pi Pico. The Pico has a soldered header, and the baseboard is socketed. Different versions of the Pico can be plugged in. Delivery includes a header version of the Pico. More information...

Common Use Cases of LIN in Vehicles

LIN buses are used for loads of small-scale functions in vehicles – especially in areas where network speed can be modest and cost needs to be low. Below are some typical automotive use cases for LIN networks:

-

Body & Comfort Systems: Power window regulators, door lock actuators, power mirror controls, sunroof controllers, and seat position motors are commonly LIN-controlled. For example, each door in a car might have a LIN bus connecting the door’s switches and motors to a door control module.

-

Steering Wheel and Dashboard Devices: Steering wheel button packs (for cruise control, audio, etc.), wiper and turn signal stalks, and climate control panels often use LIN to communicate with the main body ECU. A LIN bus can run through the steering column to read button presses or control the airbag module’s status lights.

-

Climate and Lighting: Interior climate control actuators (like air blend door motors), blower fan controllers, and sensor modules (cabin temperature, humidity, sun sensors) use LIN. Interior lighting modules, such as ambient lighting or dome lights, and even headlamp leveling motors are also LIN-based in many designs.

-

Engine Bay & Powertrain Subsystems: LIN is sometimes found in underhood applications like alternator regulators, engine cooling fan controllers, or small motor actuators, where the environment allows. It’s also used in sensor networks for transmissions or chassis when data is low-rate (e.g., ride height level sensors).

-

Auxiliary and Others: Windshield wiper systems (linking rain sensors and wiper motors), seat occupancy sensors (for airbag systems), fuel tank level sensors, trunk release mechanisms, and even battery monitoring sensors (like intelligent battery sensors) are known to use LIN in various car models.

The common theme is that LIN is chosen for non-critical, user-comfort or convenience features. These are functions where a delay of a few tens of milliseconds is acceptable and where failure is not life-threatening. By using LIN for these, manufacturers avoid overloading the primary CAN network and save cost. In a typical scenario, a central CAN-connected module (e.g., a Body Control Module or BCM) will interface with a LIN sub-network to handle these tasks. For instance, if you press a window switch on the driver’s door, a LIN message goes from the switch to the door module, which then may send a command over the CAN bus to another LIN master in the passenger door – that LIN master then activates its window motor via LIN. This kind of hierarchical network, with LIN sub-networks branching off the CAN backbone, is very common.

LIN vs CAN: Comparison with Other Automotive Networks

While LIN and CAN are both serial communication networks used in cars, they differ significantly in design and capabilities. The table below summarizes key differences between LIN and CAN buses in automotive use:

| Aspect | LIN (Local Interconnect Network) | CAN (Controller Area Network) |

|---|---|---|

| Topology & Control | Single master, up to 15 slaves (one node controls all communication – no arbitration). Only the master can initiate messages. | Multi-master bus (any node can transmit when bus is free). Uses collision avoidance/arbitration so multiple nodes can contend for bus access simultaneously. |

| Physical Wiring | Single-wire bus (plus ground). Uses vehicle battery level (~12 V) for signaling (dominant/recessive states). Master node has a 1 kΩ pull-up resistor (with diode) to battery to bias the line high; each slave has a weaker pull-up (~20–30 kΩ). No termination resistors needed. Susceptible to noise due to single-ended signaling. | Two-wire differential bus (CAN High and CAN Low) with 120 Ω termination resistors at each end of the bus. Differential signaling (typically 5 V levels) gives high immunity to electromagnetic interference. Requires proper termination and twisted-pair wiring for signal integrity. |

| Data Rate | 1 to 20 kbit/s (typical LIN buses run at 9.6 or 19.2 kbps). Low bandwidth, suitable for human-interface and slow control tasks. | Up to 1 Mbit/s for standard CAN (and even higher with CAN FD, e.g. 2–8 Mbit/s in data phase). High bandwidth for real-time control of powertrain, chassis, etc. |

| Message Handling | Master polls slaves in a fixed schedule (time-triggered communication). Deterministic timing with guaranteed latency for each message slot. Slaves only talk when spoken to. No dynamic event-driven messages (except limited use of event-triggered frames as defined by LIN). | Event-driven communication: any node can send a message when needed. If two messages occur at once, CAN’s priority-based arbitration ensures the higher-priority message wins and the lower priority is deferred without corruption. This allows spontaneous event reporting (e.g., a crash sensor can immediately send an airbag trigger message). |

| Error Handling | Basic error detection (checksum on data, ID parity bits) and an error signal if a node detects a fault. No automatic retransmission of corrupted frames – errors are handled at application or next scheduled retry. If a LIN node misbehaves, it has limited impact (the master can detect lack of response and perhaps flag an error). | Robust error detection and handling: each CAN frame has a CRC, ACK field, and error flags. Nodes automatically retransmit if a message wasn’t ACKed. Fault confinement mechanisms can force a bad node off the bus (bus-off state) if it’s disrupting communication. CAN’s error handling makes it very reliable for critical data delivery. |

| Node Cost & Complexity | Extremely low-cost nodes – often an 8-bit MCU with built-in UART and minimal software, plus a simple LIN transceiver (essentially a level shifter). Protocol is royalty-free and straightforward. Wiring is lighter (fewer wires, simpler connectors). Best for high-volume, cost-sensitive subsystems (doors, seats, etc.). | Nodes are moderately higher cost – typically a microcontroller with an integrated CAN controller or an external CAN controller chip, plus a CAN transceiver. CAN transceivers and the need for twisted-pair wiring add cost, though economies of scale keep it reasonable. Historically, CAN protocol had licensing fees (Bosch) but it’s widely accessible now. Used where performance justifies the cost (engine, ABS, etc.). |

| Use Cases in Vehicles | Non-critical, low-speed functions: body electronics and comfort features (power windows, locks, mirrors, climate control, seat adjusters, interior lights, etc.). Tolerates slight delays; an occasional lost frame is not catastrophic (e.g., a single missed button press can be retried). Typically employed in sub-networks managed by a CAN-connected module. | Critical and high-speed systems: powertrain and safety networks (engine control, transmission, braking/ABS, airbag systems, steering) and also high-speed body networks (instrument cluster, main entertainment bus). Requires real-time performance and very high reliability. CAN is often the backbone network connecting dozens of ECUs (a modern car may have multiple CAN buses for different domains). |

As shown above, LIN and CAN serve different tiers of automotive needs. LIN’s advantages are its simplicity and cost-effectiveness for localized control tasks – it uses minimal hardware and reduces wiring for things like controlling a door or a seat module. CAN, on the other hand, handles the heavy-duty communication where speed and reliability are paramount (for example, an engine control CAN bus broadcasting sensor data at 500 kbit/s). In fact, many vehicles use a hierarchical approach: critical systems talk over one or more high-speed CAN buses, while groups of LIN devices hang off a CAN node that acts as a LIN master. This way, LIN sub-networks offload the minor communications, and the CAN bus connects the major ECUs and also links the LIN clusters together.

It’s also worth noting other automotive networks: FlexRay (for very high-speed, time-critical control), MOST (for multimedia streaming), and Automotive Ethernet (for high-bandwidth data and future architectures) are used in certain areas. However, LIN remains popular for its niche – even as new technologies arise, LIN continues to be widely used for its cost-to-value efficiency.

PiCAN FD with LIN Bus for Raspberry Pi

PiCAN FD with LIN Bus for Raspberry Pi

This PiCAN FD board comes with a LIN Bus interface, and the Microchip MCP2518FD IC provides classic CAN and CAN FD, while a dsPIC33 micro-controller provides the LIN Bus connection. Communication to the Pi is per UART on ttyS0 using ASCII text commands. Example LIN-bus GUI app is available written in Python3 and tkinter.

The firmware is updatable using the Microchip UnifiedHost java app. This requires the Raspberry Pi to run in GUI mode.

Easy to install SocketCAN driver. Programming is supported in C or Python. More information...

LIN Physical Layer and Hardware Considerations

The LIN physical layer is designed for simplicity and automotive robustness on a single wire. It is standardized (LIN 2.x corresponds to ISO 17987 and is based on the older ISO 9141 K-line standard). Key hardware characteristics include:

-

Single-Wire Bus: LIN uses one signal wire, plus a common ground reference, to connect all nodes. When the bus is idle, it is pulled up to the battery voltage (typically 12 V in cars, though LIN also supports 24 V for trucks). Logical “1” on the bus is a high (near battery voltage, ~12 V) and logical “0” is a low (near 0 V), similar to an UART line but at higher voltage levels. Because it’s single-ended, all nodes must share a ground reference to interpret the bus voltage correctly.

-

Bus Transceiver and Biasing: Each node’s connection to the LIN wire is through a transceiver chip, which is essentially a level shifter (translating between the microcontroller’s logic levels and the LIN bus 12V level) with some built-in safety features. Typically, the master node’s transceiver provides the primary bus bias: at the master, a ~1 kΩ resistor (to battery) in series with a diode pulls the LIN line to high (recessive state) when no node is driving it. Each slave node also has an internal pull-up (around 20 kΩ–30 kΩ) to maintain a weak bias and prevent the line from floating. The master’s stronger pull-up ensures the bus defaults to a known high voltage and defines the recessive state. The diode in series prevents a powered-down master from sinking current from the bus (avoiding accidental back-powering of the bus through a dead node).

-

Dominant and Recessive States: LIN uses an open-collector/open-drain style signaling – any node can pull the line low (dominant), but no node actively drives it high. When no node is transmitting, the pull-ups raise the line to the high voltage (recessive). This means if two nodes transmit at the same time (which should not happen in LIN’s scheme), a dominant (0) will override a recessive (1). In normal operation, only the master or the addressed slave will be driving the line at any time. The voltage thresholds are defined such that a receiver interprets bus voltage above ~0.6 * V_bat as a logical 1 and below ~0.4 * V_bat as logical 0, with some hysteresis for noise immunity.

-

Speed and Distance: LIN is specified for up to 40 meters of bus length at the maximum 20 kbit/s rate. The relatively low baud rate and the capacitance of automotive wiring limit the practical length. In most cars, LIN buses are much shorter (limited to within a door or within the dashboard, a few meters at most). The bus can theoretically run faster on shorter lengths (some implementations allow up to ~100 kbit/s on very short cables), but standard LIN stays at 20 kbit/s or below to avoid electromagnetic interference problems on single wires.

-

EMC and Robustness: Since the LIN bus is single-ended and at battery voltage, it is more susceptible to electromagnetic noise pickup compared to CAN’s differential bus. The system mitigates this partly by the low speed (allowing filtering and avoiding high-frequency interference) and the use of checksum and parity to detect errors. LIN transceiver chips also include features like slew rate control (to reduce electromagnetic emissions by slowing down edges) and input filtering. Additionally, LIN transceivers are built to handle automotive conditions – they tolerate ±12 V or more on the bus, have ESD protection, can survive load dump transients (the LIN physical layer is often designed in line with ISO 7637 transient standards), and usually operate over the automotive temperature range (−40°C to +125°C). They also often provide a low-power sleep mode and the ability to wake up when they detect the bus wake-up signal.

-

Master Node Hardware: The LIN master’s microcontroller typically needs a stable clock source (often a crystal oscillator) because it dictates the baud rate for the whole bus. Slaves can use cheaper RC oscillators thanks to the sync field, but the master’s accuracy defines the baseline. The master also usually contains the termination (the 1 kΩ pull-up) and sometimes a series resistor to limit current in case of faults. In many implementations, the master node is part of a larger ECU that also has a CAN interface; for example, a body controller that manages a LIN network will have both a CAN transceiver (to talk to the rest of the car) and a LIN transceiver (to talk to the LIN devices).

-

Slave Node Hardware: LIN slave ECUs are designed to be as inexpensive as possible. Many 8-bit automotive microcontrollers come with LIN support (either via a LIN-enabled UART or a bit-streaming peripheral) and can run the LIN protocol stack in software. The transceiver chips for LIN are also simple and cost only a fraction of a CAN transceiver. Because slaves rely on the master for timing, they don’t need precise oscillators for long-term accuracy – the master’s sync keeps them on track frame by frame. This means cheaper resonators or internal RC clocks can be used. The slave’s internal pull-up and the network design ensure that even if a slave loses power, the diode prevents it from dragging the bus line and the bus still stays biased by the master’s resistor.

Teensy 4.0 CAN FD And LIN Bus Breakout Board

Teensy 4.0 CAN FD And LIN Bus Breakout Board

This breakout board is a powerful and compact solution designed for CAN FD and LIN Bus development using the high-performance Teensy 4.0 microcontroller (included and pre-installed). It is ideal for engineers and developers working on automotive, industrial, or custom embedded applications where seamless communication between different vehicle domains is required.

In modern vehicles, CAN (Controller Area Network) is typically used for high-speed data exchange between critical systems such as the engine control unit (ECU), transmission, and ABS, while LIN (Local Interconnect Network) is employed for simpler, low-speed tasks such as controlling mirrors, window motors, or interior lighting. This breakout board enables you to bridge those domains, acting as a custom gateway tailored to your application requirements—whether you're prototyping, simulating, or monitoring vehicle networks. More information...

Key Advantages and Limitations of LIN

Advantages of LIN:

-

Low Cost: LIN was fundamentally designed to minimize cost per node. It allows use of low-end microcontrollers (even 8-bit, no dedicated co-processor needed) and inexpensive transceiver hardware. There are no royalties for using LIN (whereas CAN, in its early days, had associated IP licensing). Additionally, using one LIN bus in place of multiple direct wire connections can significantly reduce wiring harness size, weight, and connector count. Fewer wires and simpler network topology translate to cost savings in manufacturing.

-

Simplicity: The LIN protocol is straightforward – essentially UART with a schedule. This makes it relatively easy to implement and debug. The single-master scheme means the system behavior is highly predictable (no complex arbitration logic). A LIN network’s behavior can be understood from its schedule table, and timing issues are more deterministic than on a bus where any node can transmit at will. The simplicity also means integration of new LIN nodes or changes in schedule can often be done without affecting other parts of the system (as long as the schedule is adjusted).

-

Deterministic Communication: Because LIN is schedule-driven, it offers guaranteed latency for messages. You can design a LIN cluster such that a particular signal (e.g., door lock command) is updated every, say, 20 ms with very little jitter in timing. For many control tasks in body electronics, knowing the worst-case delay is useful (even if it’s relatively long compared to CAN, it’s bounded and consistent).

-

Reduced Wiring & Weight: LIN enables multiplexing of signals that might otherwise require many separate wires. For instance, rather than running a dozen wires for each button and motor in a car door, one can use a single LIN bus wire to connect the door module and all switches/motors in the door. This reduces the weight of the wiring harness and simplifies assembly. In turn, reducing vehicle weight can have knock-on benefits like improved fuel efficiency.

-

Power Management: LIN nodes support sleep modes, allowing parts of the car to power down when not needed (for example, when the car is parked or a particular module isn’t in use). The master can wake the network on demand, or slaves can trigger a wake if an input is detected (like someone pressing a door handle button). This network-level power control helps limit battery drain in modern vehicles, which have many electronics.

-

Scalability for Add-ons: Adding a new feature or component (within reason) can be as easy as adding a new slave on a LIN bus and updating the master’s schedule. For example, if a new variant of a car adds a motorized sunshade in the sunroof, one could add a LIN-controlled motor module and schedule a new LIN frame for it. This flexibility makes LIN a convenient way to implement optional features or incremental improvements without redesigning the high-speed networks.

Limitations of LIN:

-

Limited Speed & Bandwidth: With a maximum of ~20 kbps, LIN is far slower than CAN (1 Mbps) or other networks. It’s unsuitable for real-time critical control or high-bandwidth data transfer. The low speed means that only signals that tolerate update rates on the order of tens of milliseconds or more are appropriate. For instance, LIN could not directly support something like engine fuel injection timing or high-resolution sensor streaming – those remain in CAN or other faster networks.

-

Master Single Point of Failure: The LIN bus relies on its master node for all communications. If the master ECU fails or goes offline, the entire LIN cluster becomes silent. There is no concept of a backup master or node redundancy within a LIN cluster (unlike some multi-master systems). Therefore, LIN is not used for any function where the loss of one module would cause a critical failure; it’s confined to non-critical domains where a failure might be an inconvenience (e.g., a window stuck closed) rather than a safety issue.

-

Lower Robustness and Error Resilience: LIN’s error handling is minimal – parity on the ID and a checksum on the data. It can detect single-bit errors but is not as comprehensive as CAN’s error detection (which includes cyclic redundancy checks, acknowledgment bits, and automatic retransmission). If noise corrupts a LIN message, that frame is simply lost; the master or higher-level software would have to retry it on the next schedule slot. There is no automatic retransmit on error as in CAN. Also, LIN has no built-in mechanism to remove a faulty node from the bus (no equivalent of CAN’s bus-off); a babbling LIN slave or a short on the bus can impair the whole cluster until fixed. That said, the master can notice lack of response and flag an error, but recovery is limited to higher-layer strategy (like resetting a node).

-

Noise Susceptibility: Using a single-wire, ground-referenced signal means LIN is more susceptible to electromagnetic interference and voltage offsets. In a noisy electrical environment, LIN frames can be disturbed by spikes or ground shifts. The system mitigates this by being slow and using checksums, but it’s inherently less noise-immune than differential buses. For this reason, LIN is confined to less noise-prone areas or short distances. It’s generally not used in engine compartments or alongside ignition systems without careful shielding or filtering. Additionally, a single-wire bus cannot use techniques like common-mode cancellation that differential pairs use to reject noise.

-

Throughput and Data Size Constraints: LIN frames max out at 8 bytes of data, same as classic CAN (though CAN FD extends this). While 8 bytes is enough for many simple commands or readings, anything larger or requiring fragmentation (like diagnostics, which LIN can do in a limited way) is slow and inefficient over LIN. If a device needs to send a lot of data or frequent messages, LIN will be a bottleneck. For example, transferring a firmware update or a detailed sensor waveform over LIN would be impractically slow.

-

Not Suitable for Safety-Critical Functions: Due to all the reasons above (single point of failure, no redundancy, lower error checking), LIN is not used for things that have direct safety impact. Regulations and functional safety standards (like ISO 26262) typically would not accept LIN for high ASIL (Automotive Safety Integrity Level) functions. CAN, and higher-grade networks (FlexRay, Ethernet), serve those areas. LIN’s role stays with convenience electronics.

-

Timing Flexibility: LIN’s deterministic scheduling is a double-edged sword. On one hand, it’s predictable; on the other hand, it lacks the flexibility of event-driven communication. If something unusual happens that needs immediate attention (say a sudden door latch failure detection), LIN cannot report it immediately unless a frame was already scheduled for that or you implement an event-triggered frame (with its own limitations). The fixed schedule can also waste bandwidth by polling things that haven’t changed. Thus, LIN is efficient for regular periodic data, but not as efficient as CAN in handling sporadic events without delay or wasted bandwidth. Designers must carefully choose schedule slots and frame types to balance responsiveness and bus utilization.

Despite these limitations, LIN remains highly effective for what it was designed: a cost-saving network for distributed electronics where real-time performance is not critical. Its use of a single wire and simple protocol has made it very popular for integrating the growing number of electronic features in cars (like ever-more motors, sensors, and switches in our doors, seats, mirrors, etc.). As vehicles continue to add features, LIN bus usage has grown in parallel with CAN bus growth. Engineers choosing LIN will do so knowing its niche: it’s the lightweight communications backbone for the car’s comfort and convenience features, quietly keeping the non-critical functions connected in an affordable way.

References:

-

Martin Falch, “LIN Bus Explained – A Simple Intro [2025],” CSS Electronics Guides, updated Jan 2025. Overview of LIN vs CAN, physical layer, frame format, etc.

-

Wilfried Voss, “Unlocking Vehicle Intelligence: A Practical Guide to CAN and LIN Bus Networks,”Copperhill Technologies Blog, May 22, 2025. (Detailed comparison of CAN and LIN architectures and use cases).

-

Lou Frenzel, “The LIN Interface and Automotive Interconnects—A Perfect Match,” Electronic Design, June 5, 2018. (Discusses LIN applications and basic operation, sponsored by Texas Instruments).

-

“Local Interconnect Network,” Wikipedia, last modified Oct 2025. (General LIN information, protocol features, and history).

Loading... Please wait...

Loading... Please wait...