Blog

Recent Posts

SAE J1939 Functional Safety Communications Protocol

Posted by on

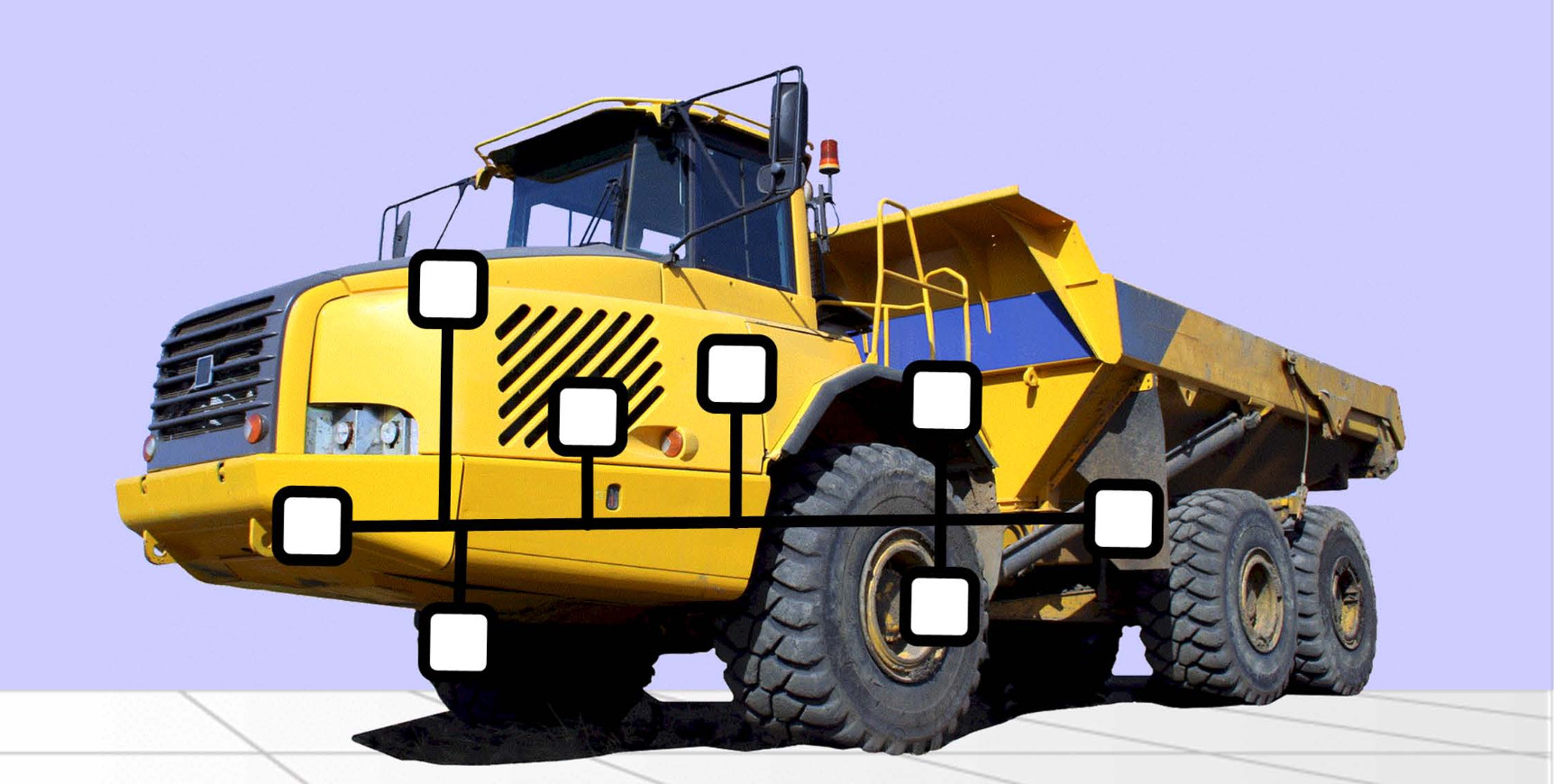

Commercial road and off-highway vehicles, as well as off-road construction machines, frequently utilize J1939-based application layers. In response to the growing need for functional safety, SAE has created specific protocols for CAN CC (classic) and CAN FD: J1939-76 and J1939-77, respectively.

An article on the CiA (CAN-in-Automation) website discusses the SAE standards for functionally safe communications on CAN CC (SAE document number 1-76) and CAN FD (SAE document number 1-77). SAE document number 1-76 describes the Safety Header Message (SHM) and Safety Data Message (SDM) pairing approach used to communicate safety-related data from a producing safety application to a consuming safety application. It also details the features of the original version, published in 2020, and lists the deficiencies of this version.

Finally, it describes the features of the updated version currently in development that address these shortcomings. In SAE J1939-77, the document explains how the space allocated for functional safety assurance information in the Multi-PG and FD Transport protocols is used to transmit safety-related data from a producing safety application to a consuming safety application. It also outlines three profiles currently being developed to meet various system needs while fulfilling functional safety requirements.

The IEC standard number 1 defines various communication errors that can occur. These errors include corruption, unintended repetition, incorrect sequence, loss, unaccepted delay, insertion, masquerade, and addressing. Additionally, the standard outlines safety measures that can be employed to detect these errors and achieve the desired level of functional safety. These measures include sequence numbers, time expectations, connection authentication, data integrity assurance, and redundancy with cross-checking.

The J1939-76 standard specifies two versions of functional safety support. This support applies to Parameter Groups (PGs) with parameter data payloads ranging from 1 to 8 bytes. Both versions use a Safety Data Group (SDG), which includes a Safety Header Message (SHM1 or SHM2) and a Safety Data Message (SDM), to transmit safety-related data from a producer to a consumer. The SDM, associated with an SHM, contains the safety-related parameter data used for a safety function.

The SAE J1939-77 standard provides three distinct profiles to support functional safety. Each profile is designed to meet different system requirements. These profiles use the Multi-PG and FD Transport protocols specified in J1939-22 for CAN FD. They can allocate a separate space in their messaging for cybersecurity and/or functional safety assurance information for a PG’s parameter data. This flexibility allows the standards to be customized to meet a wide range of system needs, from simple to complex, while meeting functional safety requirements. Read the article (PDF)...

SAE J1939 Starter Kit and Network Simulator

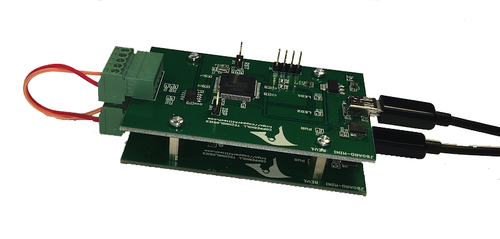

Our JCOM.J1939 Starter Kit and Network Simulator are designed to allow experienced engineers and beginners to experiment with SAE J1939 data communication without needing to connect to a real-world J1939 network, i.e., a diesel engine.

To establish a network, you need at least two nodes. This applies especially to CAN/J1939, where the CAN controller will shut down after transmitting data without receiving a response. Therefore, our jCOM.J1939 Starter Kit and Network Simulator consist of two J1939 nodes: our jCOM.J1939.USB, an SAE J1939 ECU Simulator Board with USB Port. More Information...

Loading... Please wait...

Loading... Please wait...