Blog

Recent Posts

Industrial Ethernet Guide - The Dependence On Intelligent Nodes

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

In review, any Fieldbus system (a.k.a. Distributed Control), utilizing a certain level of network management, is based on communication between one central system (Master, Server) and several nodes (Slave, Client). These nodes are nothing else but processor systems, and old technology wisdom states that an increasing number of processors results in a performance boost of the overall system.

Distributed control also translates into “distributed intelligence.” In this case, "Intelligence" represents the nodes’ capability to accomplish a significant part of their control tasks without support from the central control system. The more these nodes process internally, the less they depend on the speed of their communication means.

This circumstance is vital for slower networking technologies (e.g., CANopen and DeviceNet) when it comes to high-performance requirements such as high-speed, high-precision motion control. Even with a slower data rate of 1 Mbit/sec (compared to Ethernet’s 100/1000 Mbit/sec) and less-than-perfect bandwidth, CANopen and DeviceNet are quite capable of handling complex most motion control applications. They accomplish this by reducing the communication traffic between Master and Slaves, including direct Slave-to-Slave communication. Naturally, there are limits.

The dependence on “intelligent” nodes, however, does virtually not apply to Industrial Ethernet due to its vast speed in combination with larger data packages. Industrial Ethernet also provides enhanced support for synchronizing nodes, an important factor for real-time control.

Industrial Ethernet applications still include “intelligent” devices, specifically motion controllers, but it does not rely on, for instance, high-performance digital I/O boards. This independence on intelligent control devices simplifies many design aspects for industrial applications.

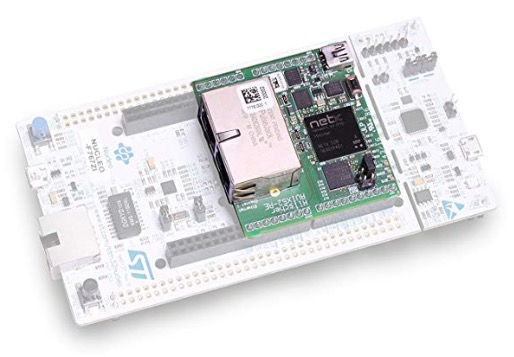

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Industrial Ethernet Guide - The Benefits of Distributed Control

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.The advantages of distributed over central control, reduced wiring and distributed intelligence, as briefly mentioned in the previous chapter, amount not only to significant cost savings through the reduction of efforts during design and operation but also opens the door to supporting application [...]

Industrial Ethernet Guide - Central Vs. Distributed Control

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.Central Control is based on a single CPU burdened with the entire automation task. Consequently, the data traffic between the CPU and the hardware interfaces is very high. Central Control requires the use of a high-performance (i.e., fast) CPU, especially when it comes to real-time control.As the blow [...]

Loading... Please wait...

Loading... Please wait...