Blog

Recent Posts

ESP32 for CAN Bus Application Developments

Posted by on

The ESP32 has become one of the most versatile microcontrollers in modern embedded development. With its dual-core processor, integrated Wi-Fi and Bluetooth, and robust peripheral set, it is a natural fit for advanced networking and control applications. One of its rising uses is in Controller Area Network (CAN Bus) systems, where the ESP32 provides both the processing horsepower and flexibility needed for industrial, automotive, and IoT applications.

The ESP32 has become one of the most versatile microcontrollers in modern embedded development. With its dual-core processor, integrated Wi-Fi and Bluetooth, and robust peripheral set, it is a natural fit for advanced networking and control applications. One of its rising uses is in Controller Area Network (CAN Bus) systems, where the ESP32 provides both the processing horsepower and flexibility needed for industrial, automotive, and IoT applications.

The ESP32’s Strengths in CAN Bus Development

Powerful Processor Architecture

At its core, the ESP32 features a dual-core Tensilica Xtensa processor running up to 240 MHz. This performance level allows developers to handle real-time CAN message parsing, filtering, and higher-layer protocol implementations without overloading the system. Unlike simpler MCUs, the ESP32 can run CAN tasks alongside networking functions, such as remote monitoring over Wi-Fi or Bluetooth, without sacrificing responsiveness.

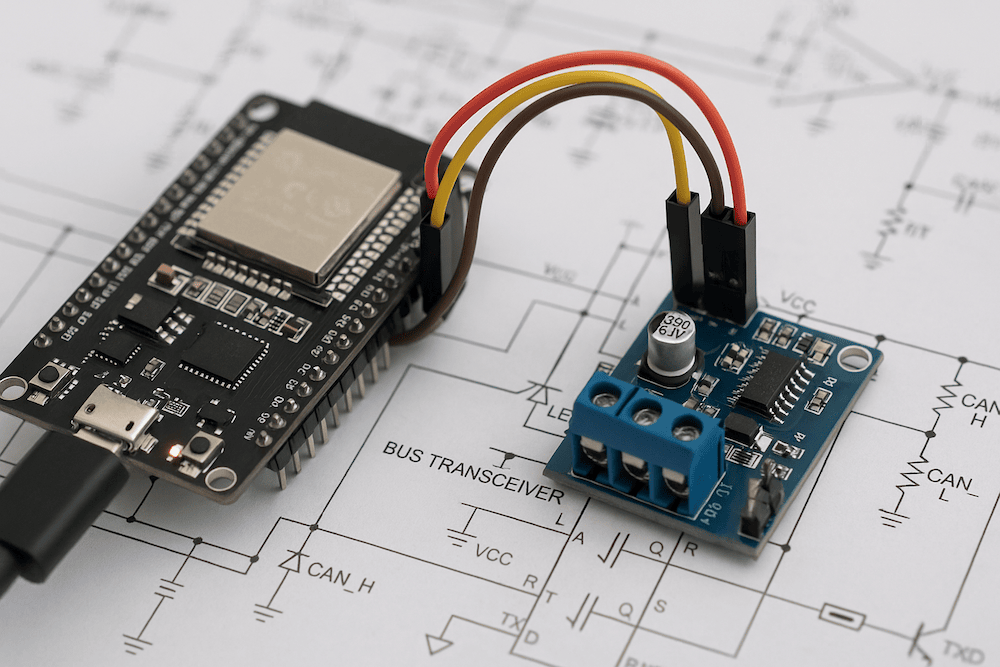

Integrated Peripherals and Flexibility

The ESP32 includes a built-in CAN controller, eliminating the need for external components to handle basic CAN protocol functions. With the addition of a transceiver, developers can immediately connect to CAN networks. Its multiple GPIOs and flexible pin mapping make it adaptable for different bus layouts and interface requirements.

Memory and Storage Benefits

The chip provides ample SRAM and flash support, which is crucial for buffering CAN frames, storing diagnostic data, and even running more complex CAN-based applications like J1939, NMEA 2000, or custom proprietary protocols. This ensures that developers can scale from simple gateways to feature-rich network nodes.

CAN Bus Applications with ESP32

Thanks to its feature set, the ESP32 enables:

-

CAN to Wi-Fi Gateways – bridging vehicle or industrial networks with cloud-based monitoring tools.

-

Data Loggers – storing CAN frames locally for diagnostics and later retrieval.

-

Custom Control Nodes – creating intelligent devices that act as active participants in a CAN network, not just passive monitors.

-

IoT Extensions – integrating CAN-based devices into broader IoT ecosystems using MQTT or REST APIs.

Programming the ESP32 with the Arduino IDE

Accessibility and Simplicity

One of the strongest appeals of the ESP32 platform is its compatibility with the Arduino IDE. Developers who already have experience with Arduino boards can seamlessly transition into ESP32 programming without a steep learning curve.

Wide Range of Libraries

Within the Arduino ecosystem, a large number of open-source CAN libraries are readily available. These provide abstractions for sending, receiving, and filtering CAN frames, significantly reducing development time. Higher-level protocol libraries (e.g., J1939 or NMEA 2000) can be built on top of these, leveraging existing community support.

Cross-Function Development

Using Arduino IDE, developers can write multi-functional applications: for example, an ESP32 that not only communicates over CAN but also sends data via Wi-Fi to a cloud dashboard. The Arduino IDE makes it straightforward to combine these capabilities in a single sketch.

Advantages of the ESP32 + Arduino IDE Approach

-

Fast Prototyping – rapid setup and coding mean ideas can be tested quickly.

-

Low Cost, High Performance – ESP32 boards remain inexpensive compared to dedicated CAN-enabled microcontrollers.

-

Community Support – large user base ensures a wealth of shared projects, examples, and troubleshooting tips.

-

Expandable – easy integration of additional sensors, displays, and connectivity features beyond CAN.

Conclusion

The ESP32 stands out as an excellent platform for CAN Bus development. Its processing power, integrated CAN controller, and wireless connectivity allow engineers and hobbyists alike to create advanced, connected systems with minimal cost and complexity. When combined with the Arduino IDE, development becomes accessible, flexible, and efficient—making the ESP32 a cornerstone in the future of embedded CAN Bus applications.

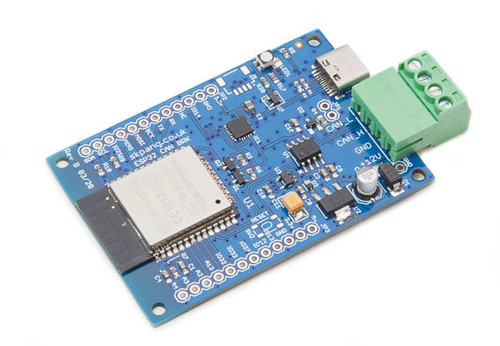

Highlight: Two ESP32 / CAN Bus Modules from Copperhill Technologies

Copperhill Technologies offers two versatile ESP32-based boards tailored for CAN Bus development. The first is an ESP32 module with Wi-Fi, Bluetooth Classic, BLE, and built-in support for Classical CAN 2.0B, making it ideal for gateways, diagnostics, and wireless-enabled monitoring systems where compact design and straightforward integration matter most. The second, a more advanced ESP32-S3 board, expands capabilities with larger memory, floating-point support, native USB, and both Classical CAN and CAN FD connectivity through an onboard transceiver and external controller, backed by a wide voltage input range and rugged power design. Together, these boards provide developers with flexible options, from simple wireless-CAN applications to robust, next-generation automotive and industrial solutions.

ESP32 WiFi, Bluetooth Classic, BLE, CAN Bus Module

-

Based on the ESP32-WROOM-32 module: dual-core Xtensa LX6 running up to 240 MHz, with about 520 KB of SRAM (around 448 KB usable for applications) and 4 MB of flash.

-

Wireless connectivity includes full Wi-Fi support plus Bluetooth Classic and BLE.

-

On the CAN side, it supports Classical CAN 2.0B, handling both standard (11-bit) and extended (29-bit) identifiers through the ESP32’s integrated CAN controller and an onboard CAN transceiver.

Electrical and I/O Features

-

Powered via Micro USB or external headers, with an onboard regulator for 5 V to 3.3 V conversion.

-

Multiple GPIOs are available for UART, SPI, I²C, I²S, and analog inputs.

-

Includes a USB-UART bridge for programming and debugging, along with status LEDs.

CAN Bus Capabilities & Limitations

-

Supports Classical CAN at speeds up to 1 Mb/s.

-

Features programmable bit timing, acceptance filtering, and interrupt-driven communication.

-

Does not natively support CAN FD, though external controllers could be added if needed.

Ideal Use Cases

-

Projects requiring wireless connectivity alongside Classical CAN.

-

CAN to Wi-Fi/Bluetooth gateways, diagnostics, or monitoring tools.

-

Compact prototypes where minimal external components are preferred.

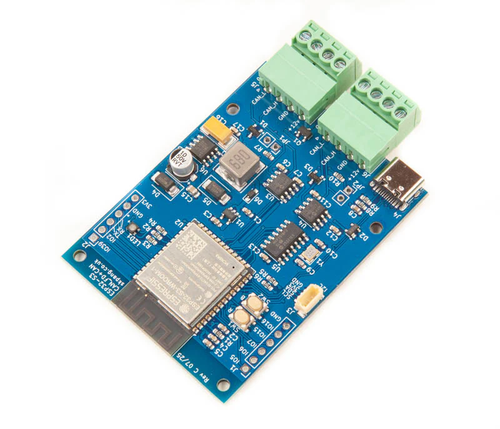

ESP32-S3 Board with CAN FD and Classical CAN Ports

-

Built around the ESP32-S3-WROOM-1-N8R8 module with a dual-core Xtensa LX7 processor running up to 240 MHz.

-

Provides enhanced resources, including 8 MB of flash and 8 MB of PSRAM, ideal for applications needing large data buffers or more complex firmware.

-

Includes floating-point capability for heavier computations.

Wireless & Peripheral Features

-

Offers Wi-Fi, Bluetooth 5, BLE, and optional Bluetooth mesh.

-

Features a native USB OTG/USB device interface for direct programming and debugging, eliminating the need for a separate USB-UART bridge.

CAN Bus Capabilities

-

Handles Classical CAN through the ESP32-S3’s integrated controller.

-

Supports CAN FD via an external MCP2518FD controller connected over SPI, providing compatibility with both legacy and next-generation networks.

-

Includes high-speed CAN transceivers for robust bus operation.

Power, I/O & Extra Features

-

Wide input voltage range (7 V to 24 V) supported by onboard SMPS, with reverse polarity protection for reliability in automotive or industrial settings.

-

Features USB-C connector, boot and reset buttons, expansion port for I²C, and RGB status LED.

Use Cases & Advantages

-

Ideal when both Classical CAN and CAN FD are required.

-

Suitable for demanding applications requiring larger buffers, heavier calculations, or secure communication.

-

Designed for environments with higher and variable input voltages.

-

Simplified development workflow thanks to native USB and expanded memory.

Comparison & Decision Points

| Factor | ESP32 WiFi/Bluetooth + Classical CAN | ESP32-S3 with Classical CAN + CAN FD |

|---|---|---|

| CAN FD support | Not supported natively | Supported via external controller |

| Memory resources | 4 MB flash, ~448 KB usable SRAM | 8 MB flash + 8 MB PSRAM |

| USB / Programming | USB-UART bridge | Native USB OTG |

| Power input | Standard USB or 5 V headers | 7–24 V with SMPS and reverse polarity protection |

| Processing | Dual-core LX6, no FPU | Dual-core LX7, with floating-point and expanded compute |

ESP32, the low-cost, energy-efficient system-on-a-chip (SoC) microcontroller, has become a cornerstone of modern Wi-Fi-enabled devices, driving innovation across the Internet of Things (IoT) landscape. This comprehensive guide offers a practical, end-to-end approach to building secure, scalable IoT systems using the powerful ESP32 platform.

ESP32, the low-cost, energy-efficient system-on-a-chip (SoC) microcontroller, has become a cornerstone of modern Wi-Fi-enabled devices, driving innovation across the Internet of Things (IoT) landscape. This comprehensive guide offers a practical, end-to-end approach to building secure, scalable IoT systems using the powerful ESP32 platform.

From foundational concepts to advanced implementation, the book walks you through the complete lifecycle of developing an IoT device with ESP32. Beginning with essential IoT principles and real-world use cases, each chapter progressively builds your skills—covering sensor communication, integration of key libraries like LittleFS and LVGL, Wi-Fi connectivity, data security, and cloud integration. You'll also learn how to visualize real-time data using tools like Grafana, making your solutions truly production-ready.

A special section is dedicated to artificial intelligence and machine learning (AI/ML) for embedded systems. You'll explore how to build and deploy tinyML models on the ESP32-S3, enabling intelligent edge computing capabilities for your next-generation embedded products.

Adopting a hands-on, project-driven approach, the book ensures that you can apply your knowledge from day one. As a capstone, you'll develop a full-scale Smart Home system, consolidating all the concepts and technologies explored throughout the book.

Whether you're a maker, engineer, or embedded systems developer, this book equips you to build secure, real-world IoT solutions with ESP32—ready for deployment in today’s connected world. More information...

Exploring the PiCAN Series and SocketCAN: A Powerful Duo for Raspberry Pi CAN Bus Applications

The PiCAN series from Copperhill Technologies brings robust CAN Bus capabilities to Raspberry Pi systems, providing essential tools for automotive, industrial, and robotics projects. These boards are compact, powerful, and compatible with SocketCAN, the standard CAN interface for Linux systems. Whether you’re developing diagnostic tools, data loggers, or real-time communication systems, PiCAN HATs offer a [...]

The MCP2515 and MCP2518FD CAN Controllers – The Core of Copperhill Technologies' CAN-Based Designs

At Copperhill Technologies, we specialize in embedded systems and CAN (Controller Area Network) applications for industrial, automotive, and marine environments. Our products are built to serve professionals and engineers who need reliable, real-time communication across a variety of platforms. One of the most critical decisions in any CAN-based hardware design is the selection of the [...]

Developing CAN and CAN FD Applications with the Teensy 4.1 Triple CAN Bus Board and IPS Display

As embedded systems continue to evolve, the demand for robust, real-time communication interfaces like Controller Area Network (CAN) and CAN FD (Flexible Data-rate) is rapidly increasing across multiple industries. Whether you're building electronic control systems for vehicles, developing automation networks in factories, or integrating sensors and instruments on marine vessels, CAN Bus remains the gold [...]

Technical and Development Report: Teensy 4.0 OBD-II CAN-Bus ECU Simulator

1. Introduction As the automotive industry becomes increasingly software-driven, the demand for rapid prototyping, diagnostics development, and ECU (Engine Control Unit) emulation tools has grown exponentially. The Teensy 4.0 OBD-II CAN-Bus ECU Simulator from Copperhill Technologies offers a compact, powerful, and affordable solution for developers, educators, and engineers working on automotive diagnostic tools or embedded control [...]

Combining CAN Bus and Microcontroller Power: The CANPico V2 by Copperhill Technologies

In the realm of embedded systems and industrial automation, two technologies stand out for their versatility and functionality: the Controller Area Network (CAN) and the Raspberry Pi Pico. Together, they offer robust possibilities for real-time communication and compact control systems. Copperhill Technologies has leveraged this synergy by introducing the CANPico V2, a powerful development board [...]

The PiCAN3 CAN Bus Board for Raspberry Pi: A Comprehensive Development Environment for CAN Bus Applications

The PiCAN3 CAN Bus Board, available from Copperhill Technologies, is a powerful and versatile hardware expansion for the Raspberry Pi. Designed to support CAN (Controller Area Network) applications, this board enables developers to turn their Raspberry Pi into a professional-grade platform for embedded system development in automotive, industrial, and other demanding environments. PiCAN3 CAN Bus Board [...]

Loading... Please wait...

Loading... Please wait...