Recent Posts

Proper Controller Area Network (CAN) Wiring and Connectors

Posted by on

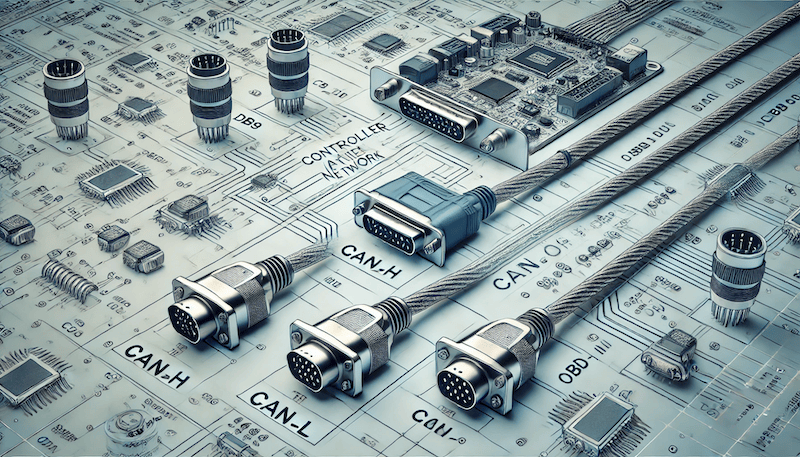

Controller Area Network (CAN) is a robust, high-integrity serial bus system originally developed by Bosch in the 1980s for automotive applications. Today, CAN is widely used in automotive, industrial, and embedded systems due to its fault tolerance, real-time performance, and reduced wiring complexity. However, the reliability of CAN communication heavily depends on proper wiring practices and connector usage. This essay provides a comprehensive overview of correct CAN wiring and connector implementation to ensure optimal performance and data integrity.

Controller Area Network (CAN) is a robust, high-integrity serial bus system originally developed by Bosch in the 1980s for automotive applications. Today, CAN is widely used in automotive, industrial, and embedded systems due to its fault tolerance, real-time performance, and reduced wiring complexity. However, the reliability of CAN communication heavily depends on proper wiring practices and connector usage. This essay provides a comprehensive overview of correct CAN wiring and connector implementation to ensure optimal performance and data integrity.

1. CAN Bus Topology

1.1 Linear Bus Structure

CAN networks are designed around a linear (bus) topology with two terminators at each end. All nodes tap into this main bus, but stubs (short branches to nodes) must be kept as short as possible to minimize signal reflection and preserve signal integrity.

-

Main Bus: One twisted pair cable, carrying CAN_H and CAN_L, running through the entire network.

-

Stubs: Connections from the bus to individual CAN transceivers; typically limited to < 0.3 meters (1 foot) for high-speed systems.

1.2 Star and Ring Topologies

Star and ring configurations are not recommended for high-speed CAN (ISO 11898-2) as they lead to signal reflection and timing issues. However, limited star configurations are acceptable in low-speed fault-tolerant CAN (ISO 11898-3).

2. Cable Specifications

2.1 Twisted Pair Cable

A shielded or unshielded twisted pair (STP/UTP) cable is required for CAN_H and CAN_L to reduce electromagnetic interference (EMI) and maintain signal quality.

-

Characteristic impedance: 120 Ω ±10%

-

Capacitance: < 30 pF/ft (98.4 pF/m)

-

Wire gauge: 22 AWG to 24 AWG for most applications

-

Shielding: Optional for noise-sensitive environments; grounded at a single point to avoid ground loops

2.2 Wire Colors (optional standardization)

-

CAN_H: White or Yellow

-

CAN_L: Blue or Green

-

Consistency across devices is crucial for diagnostics and maintenance

3. Termination Resistors

3.1 Function

Termination resistors prevent signal reflection at the ends of the CAN bus. They also define the common-mode voltage level and improve noise immunity.

3.2 Specifications

-

Value: 120 Ω ±1%, 0.25W or greater

-

Location: One at each physical end of the main bus (not on stubs)

-

Resulting load: Two 120 Ω resistors in parallel yield a total bus impedance of 60 Ω

Note: Only two termination resistors are allowed on the bus—additional terminations cause excessive load and weaken signal strength.

4. Connectors

While CAN bus does not mandate specific connectors, several industry standards and practices have emerged depending on the application domain.

4.1 Common Connector Types

a. DB9 (D-sub) — CiA 303-1 Standard (used in industrial automation)

-

Pinout:

-

Pin 2: CAN_L

-

Pin 3: GND

-

Pin 7: CAN_H

-

Pin 9: +V (optional, 5V or 12V)

-

-

Usage: Allows easy tool integration and diagnostic access

b. OBD-II (J1962) — Automotive diagnostic interface

-

Pin 6: CAN_H

-

Pin 14: CAN_L

-

Pin 4/5: Ground

-

Pin 16: Battery Power

c. M12 Connector — IEC 61076-2-101 (industrial and rugged environments)

-

Common in IP67-rated devices; provides secure, vibration-resistant connections

-

A-coded or D-coded variants with 4- or 5-pin configurations

d. RJ45 / Ethernet Connectors — Not standardized for CAN but sometimes used in custom or legacy systems

-

Use with caution; not ideal for automotive-grade vibration or EMI protection

5. Grounding and Shielding

Proper grounding and shielding are essential to avoid common-mode voltage mismatches and electromagnetic interference.

-

Shield grounding: At one location only (preferably at the power source or gateway ECU)

-

CAN GND: Include a dedicated ground wire to maintain a common reference among all nodes

-

Ground loops: Avoid multiple ground paths to prevent interference

6. Wiring Best Practices

| Best Practice | Description |

|---|---|

| Keep stubs short | < 0.3 m to avoid reflections |

| Use twisted pair cable | Ensures signal integrity and noise immunity |

| Match termination impedance | 120 Ω at each end, no more, no less |

| Maintain consistent wire colors | Improves troubleshooting and documentation |

| Avoid splices and T-connections | Increases reliability and reduces errors |

| Test with an oscilloscope | Check for reflections, noise, and proper voltage levels |

| Label connectors and nodes clearly | Aids in maintenance and reduces risk of misconnection |

7. Signal Characteristics

7.1 Voltage Levels (ISO 11898-2, High-Speed CAN)

| Condition | CAN_H (V) | CAN_L (V) | Differential (V) |

|---|---|---|---|

| Recessive (idle) | ~2.5 V | ~2.5 V | ~0 V |

| Dominant | ~3.5 V | ~1.5 V | ~2 V |

7.2 Propagation Delay

-

Cable delay: approx. 5 ns/m

-

Total bus length must accommodate bit timing at desired baud rate (e.g., ~40 m max for 1 Mbps)

8. Testing and Diagnostics

-

Continuity test: Verifies cable integrity and correct pinout

-

Resistance test: With power off, confirm 60 Ω between CAN_H and CAN_L

-

Oscilloscope: Use to observe waveform quality, noise, and voltage levels

-

CAN analyzers: Monitor message traffic, detect bus errors, and validate baud rates

Conclusion

Proper CAN bus wiring and connector implementation is crucial for the reliability and efficiency of any distributed control system. By adhering to standardized cabling, topologies, termination practices, and connector pinouts, engineers can ensure robust performance, minimize EMI susceptibility, and simplify system diagnostics. Following these best practices is essential in both automotive and industrial environments where safety and uptime are critical.

Modern vehicles—especially those built in the last 15 years—rely heavily on electronic control units (ECUs) and computer systems that connect to virtually every major function of the car. Yet, when an error code appears or a system malfunctions, many automotive enthusiasts are unsure how to diagnose or fix the problem without taking the vehicle to a dealership, where labor rates often exceed $100 per hour.

In this comprehensive guide, Keith McCord demystifies the world of onboard diagnostic systems. He traces the evolution of automotive diagnostics from the early OBD-I systems to the now-standard OBD-II (On-Board Diagnostics II). McCord explains not only how the system works, but how to access it, interpret the data, and, most importantly, use that information to identify and resolve issues effectively.

With the help of this book, a consumer-grade handheld scanner, and basic tools, the average car enthusiast can confidently troubleshoot and repair many common vehicle problems. McCord breaks down the structure of diagnostic trouble codes (DTCs), explains the logic behind their numbering, and provides a detailed table of frequently encountered codes.

But reading codes is only the beginning. McCord goes further by offering a step-by-step troubleshooting methodology—showing how to trace issues to their root cause, understand the limitations of DTCs, and recognize when multiple systems may be contributing to a single fault. His insights empower readers to fix problems correctly the first time, avoiding costly repeat repairs or unnecessary part replacements.

This guide is an essential resource for anyone looking to take control of their vehicle’s diagnostics and repairs—without the dealership price tag. More information...

Loading... Please wait...

Loading... Please wait...

Automotive Diagnostic Systems: Understanding OBD-I & OBD-II

Automotive Diagnostic Systems: Understanding OBD-I & OBD-II