Recent Posts

Understanding SAE J1939: A Comprehensive Guide to Monitoring, Simulation, and Development

Posted by on

In the realm of heavy-duty vehicles and industrial equipment, communication between electronic control units (ECUs) is essential. To achieve this, standardized protocols are used to ensure that data is transmitted accurately and efficiently. Among these standards, SAE J1939 stands out as a dominant communication protocol, particularly in sectors like commercial trucks, agricultural machinery, and construction equipment. Understanding and working with this protocol can be a daunting task for newcomers, but it becomes manageable with the right tools and foundational knowledge. This essay explores the essentials of SAE J1939, focusing on monitoring, simulation, and development, based on insights from JCOM1939’s detailed beginner’s guide (Source: https://jcom1939.com/beginners-guide-to-sae-j1939-monitoring-simulation-and-development/).

In the realm of heavy-duty vehicles and industrial equipment, communication between electronic control units (ECUs) is essential. To achieve this, standardized protocols are used to ensure that data is transmitted accurately and efficiently. Among these standards, SAE J1939 stands out as a dominant communication protocol, particularly in sectors like commercial trucks, agricultural machinery, and construction equipment. Understanding and working with this protocol can be a daunting task for newcomers, but it becomes manageable with the right tools and foundational knowledge. This essay explores the essentials of SAE J1939, focusing on monitoring, simulation, and development, based on insights from JCOM1939’s detailed beginner’s guide (Source: https://jcom1939.com/beginners-guide-to-sae-j1939-monitoring-simulation-and-development/).

What is SAE J1939?

SAE J1939 is a high-level protocol that operates on the Controller Area Network (CAN) bus. It was developed by the Society of Automotive Engineers (SAE) to serve as a standardized method for communication and diagnostics across different ECUs in heavy-duty and commercial vehicles. At its core, J1939 provides a framework for how data is organized, identified, and transmitted over the CAN network.

The protocol is built upon a 29-bit identifier system, using what’s known as the Parameter Group Number (PGN). Each PGN defines a specific message or function, and within each message, individual pieces of information are categorized as Suspect Parameter Numbers (SPNs). These SPNs represent specific data points, such as engine speed, fuel consumption, or coolant temperature.

The Importance of Monitoring

Monitoring J1939 data traffic is a crucial first step for developers, engineers, and technicians who want to understand or troubleshoot vehicle systems. Real-time monitoring allows users to see how ECUs are interacting, what data is being shared, and whether communication errors or anomalies exist.

To monitor J1939 traffic, users need a CAN interface device capable of interpreting and displaying J1939 messages. Some of the most common tools include USB-to-CAN adapters paired with software that decodes the 29-bit identifiers and displays human-readable PGN and SPN data.

JCOM1939 provides software tools specifically designed for this purpose. Their JCOM1939 Monitor can filter and analyze live data from the CAN bus, offering features like message logging, timestamping, and message interpretation. These tools help users understand complex vehicle networks without having to manually decode binary data.

Simulation: Building a Virtual Environment

Simulation plays a vital role in the development and testing of J1939-compatible devices. Instead of connecting directly to a real vehicle or test bench, simulation allows developers to create virtual ECUs that behave like real devices on the CAN network. This is particularly useful during the prototyping phase when real hardware might not yet be available.

JCOM1939's simulation tools allow users to configure and broadcast custom J1939 messages to mimic the behavior of vehicle systems. Developers can simulate engine messages, transmission controls, or any other PGNs relevant to their application. This helps test how a receiving device responds to expected (or unexpected) data without the risks or limitations of using real equipment.

The flexibility to simulate both periodic and event-driven messages is especially valuable. For example, an ECU might send engine RPM data every 100 milliseconds, while an error code is only broadcast when a fault is detected. Accurate simulation of these behaviors ensures robust testing and validation.

SAE J1939 Starter Kit And Network Simulator

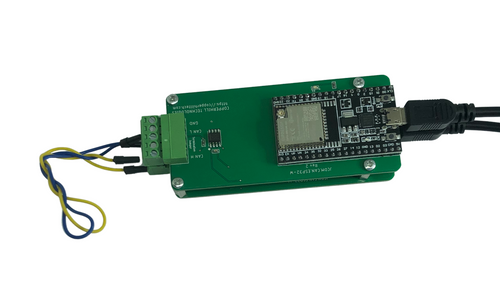

SAE J1939 Starter Kit And Network Simulator

Our SAE J1939 Starter Kit enables you to monitor, simulate, and record any PGN defined in the SAE J1939-71 standard, as well as diagnostic messages according to SAE J1939-73. Many users ask whether the kit supports specific parameters such as fuel consumption, vehicle speed, or GPS position. The answer is yes—but with an important caveat: the kit is not pre-configured for any particular engine or parameter set. To retrieve or simulate specific data, you must know the associated PGNs.

Please note that the starter kit is not designed to replicate a specific diesel engine out of the box. However, if you provide the full set of PGNs relevant to a given engine, you can effectively design and simulate its behavior using our system. More information...

Development: Creating J1939-Compliant Solutions

Developing devices that communicate over J1939 requires a solid understanding of the protocol’s message structure, timing, and behavior. J1939 is more than just a data transmission standard—it encompasses complex rules for address claiming, transport protocols, and message prioritization.

When developing a J1939 node, engineers must ensure their device adheres to rules like address arbitration and network management. For instance, each ECU must claim a unique source address when it joins the network, and conflicts must be resolved using specific arbitration procedures.

Tools from JCOM1939 help developers manage these complexities. Their development kits include libraries and sample code that abstract many low-level details of the protocol, allowing engineers to focus on core functionality. These kits are particularly helpful for those using microcontrollers or embedded systems, where memory and processing power may be limited.

Additionally, JCOM1939 supports both standard and proprietary PGNs, allowing developers to implement custom messages while remaining compliant with J1939 rules. This capability is vital for manufacturers creating specialized equipment or features not defined in the public J1939 specification.

Challenges and Considerations

Despite its benefits, working with J1939 does present challenges. The protocol’s structure is intricate, and proper implementation requires careful planning and thorough testing. Timing issues, improper PGN configuration, or address conflicts can lead to communication failures that are difficult to diagnose without the right tools.

Another common hurdle is data interpretation. While PGNs and SPNs are standardized, their values often need to be scaled or converted according to specific formulas. This adds another layer of complexity when trying to extract meaningful information from raw CAN data.

Security is another emerging concern. As vehicles become more connected, the need for secure communication increases. While J1939 was not originally designed with cybersecurity in mind, developers now need to consider encryption, authentication, and data integrity measures when designing systems that interface with critical vehicle controls.

Conclusion

SAE J1939 is a cornerstone protocol for communication in heavy-duty vehicles, enabling seamless interaction between diverse electronic systems. For newcomers, diving into J1939 can be intimidating due to its technical depth and strict specifications. However, with the right guidance and tools—such as those offered by JCOM1939—users can effectively monitor, simulate, and develop J1939-compatible solutions.

By breaking down the protocol into manageable components—PGNs, SPNs, message timing, address claiming—engineers and technicians can build a strong foundation for working within J1939 networks. Tools that simplify monitoring and simulation not only aid in understanding the protocol but also accelerate development cycles and improve product reliability.

As the industry moves toward increasingly complex and connected systems, mastering J1939 remains a valuable skill. Whether one is debugging a vehicle ECU, designing a telematics gateway, or developing a new control system, the ability to interface effectively with J1939 networks is essential. With resources like JCOM1939’s beginner’s guide, even those new to CAN bus technology can begin their journey with confidence.

Loading... Please wait...

Loading... Please wait...