Recent Posts

Thomson Electrac HD Linear Actuator - Fatal Error Flag at Low Speed

Posted by on

As part of a customer project, I was asked to develop a hardware system to control a linear actuator, specifically the Thomson Electrac HD model with SAE J1939 interface. The Electrac Linear Actuator is a great product, and it is always rewarding to see the application move. Yet, working on this application was, at times, frustrating. After months of working with this product (time frame, not efforts), I still discovered undocumented “oddities." Unfortunately, the support from Thomson I received was, at best, mediocre. I’ll leave it at that.

Let me refer first to two previous posts I wrote on the subject:

- Thomson Electrak Linear Actuator with SAE J1939 Interface for Railway and Industrial Applications Thomson...

- Electrak HD Linear Actuator - Multiple Actuators in the Same Network Will Empty the Batteries...

In this post, I will address a somewhat difficult issue involving mechanical wear. Let me say that the opinions on this issue differ between my observations and the comments I received from Thomson.

Problem Description: At random times, when starting a motion at the lowest speed (20% motor duty cycle), the actuator sets and reports the “Fatal Error Flag.” Strangely, the error occurs mostly when the actuator retracts, i.e., moves toward the zero position.

During tests at the lowest linear speed, my application detected error feedback from the actuator. The good side is that this situation forced me to include a detailed error messaging system, showing that the error reported was the Fatal Error Flag.

According to the user manual, the Speed Command’s value (Motor Duty Cycle) ranges from 20% to 100% with a 5% resolution, resulting in a range between 4 and 20. In my app, I verify the lower and upper limits of the speed potentiometer readings to keep the range between 4 and 20.

Again, according to the user manual, the Fatal Error flag “is used to inform the user that the actuator needs service.”

This explanation struck me as odd since my setup contained brand-new actuators that had been used very little compared to real-world applications, i.e., harsh industrial environmental conditions and operations. Furthermore, there is no additional load, i.e., the actuators run “free.”

Another side effect makes this situation even more unpredictable: Once the error is cleared, you can move the actuator without problem, unless you change the move direction. Furthermore, the error does not occur when you start at higher speed and then decelerate to lowest speed.

After contacting Thomson, I received a response containing more details but no solution: “If you only see the error when changing direction, it is almost certainly caused by the mechanical play. The unit will realign itself when changing direction; if the mechanical play is too big, the input signal from the position sensor will be affected, making the unit believe it is not running or running in the wrong direction. You should be able to notice if the mechanical play is too high by pushing/pulling on the extension tube. It shouldn’t almost move at all when doing this.”

Needless to say, between my customer and the setup in my office, four actuators reported the same error, and none of them showed mechanical plays. However, I must add that my customer’s setup had been used extensively. Consequently, their problems were much more accentuated than mine, which indicates higher wear and thus confirms Thomson’s statement.

Solution: One (not very satisfactory) solution is to increase the minimum allowed speed because the error does not occur at higher speeds. However, that may not be acceptable for some applications. Ignoring the error flag doesn’t help since the actuator stops by itself.

The other solution was to apply a higher speed than 20% duty cycle for a limited time after motion start, which naturally required more software development efforts. Applying a duty cycle of 30% for 400 milliseconds, then switching back to 20%, worked reliably. However, these settings may vary from setup to setup depending on the actuators’ wear.

Given Thomson’s statement, my solution may hide actuator wear from the user. Yet, the effect shows only at the lowest motor duty cycle, i.e., the actuator is in working condition. But during our tests, all actuators ran without mechanical load and showed no mechanical play, which contradicts Thomson's statement.

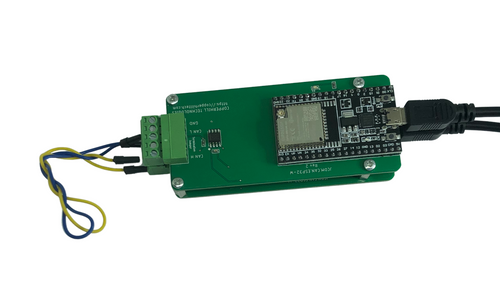

SAE J1939 Starter Kit And Network Simulator

The SAE J1939 starter kit allows you to monitor, simulate, and record any PGN as defined in the SAE J1939-71 Standard but also including diagnostic messages according to SAE J1939-73.

The starter kit was not designed to simulate specific diesel engines, but if you enter all PGNs that are being used, you can design and simulate any diesel engine.

Loading... Please wait...

Loading... Please wait...