Blog

Recent Posts

Comparing Embedded System Choices for CAN Bus: Arduino, Teensy, and ESP32

Posted by on

At Copperhill Technologies, we frequently receive inquiries asking us to recommend the “best” embedded system for CAN Bus applications. It’s a fair question, but unfortunately, there is no universal answer. The choice depends heavily on a user’s technical knowledge, development experience, and—most importantly—the specific requirements of their application.

At Copperhill Technologies, we frequently receive inquiries asking us to recommend the “best” embedded system for CAN Bus applications. It’s a fair question, but unfortunately, there is no universal answer. The choice depends heavily on a user’s technical knowledge, development experience, and—most importantly—the specific requirements of their application.

Instead of prescribing a one-size-fits-all solution, we would like to present some insights that may help you make the right decision for your project.

CAN Bus Development: With and Without an Operating System

One of the first distinctions to understand is the difference between using a microcontroller-based system such as Arduino, Teensy, or ESP32, versus a single-board computer such as a Raspberry Pi running Linux.

-

Raspberry Pi + Linux OS:

A Raspberry Pi operates like a “mini-PC.” You run Linux on it, which gives you access to a rich set of drivers, programming languages, and utilities. However, it also means additional complexity: system setup, OS-level maintenance, multi-tasking overhead, and less predictable real-time performance. -

Arduino, Teensy, ESP32 (No OS):

These microcontroller-based systems run bare-metal code or minimal firmware without the need for a full operating system. The advantage here is real-time performance, lower complexity, and direct hardware access—features that are especially important for CAN Bus applications, where timing and reliability are critical.

At Copperhill Technologies, we offer both Raspberry Pi and microcontroller solutions. However, this post focuses specifically on CAN Bus developments without an OS, where Arduino, Teensy, and ESP32 dominate.

Arduino, Teensy, and ESP32 at a Glance

Each of these platforms has its strengths. Below is a high-level overview:

-

Arduino

Arduino is known for its simplicity and ease of use. It’s the go-to platform for beginners thanks to its large ecosystem, well-documented libraries, and active community. For CAN Bus, it works reliably but may show performance limits in more demanding applications due to its lower CPU power compared to Teensy or ESP32. -

Teensy

Teensy boards (developed by PJRC) are powerful microcontrollers, offering high clock speeds and impressive I/O capabilities. The Teensy 4.0, for instance, runs at 600 MHz—far exceeding typical Arduino performance. This makes it an excellent choice for more demanding CAN Bus tasks where speed, memory, and flexibility matter. Teensy also supports both Classical CAN and CAN FD (depending on the hardware variant). -

ESP32

The ESP32 adds another layer of flexibility by combining strong CPU performance with built-in WiFi and Bluetooth. For applications where CAN Bus communication must integrate with wireless connectivity or IoT features, ESP32 is hard to beat. The ESP32-S3 also supports CAN FD, giving it an edge in modern automotive and industrial applications.

Development Tools and Ecosystem

In terms of programming, all three systems—Arduino, Teensy, and ESP32—are supported by the Arduino IDE, which makes switching between platforms straightforward.

This commonality provides a significant advantage:

-

You can use the same development environment.

-

Extensive open-source libraries and example code are readily available at github.com.

-

Code portability between platforms is achievable with minor adjustments.

As a result, development for all three platforms can be described as fast, approachable, and well-supported.

Comparing Technical Features

When choosing between Arduino, Teensy, and ESP32, it is important to evaluate both functionality and CPU performance:

-

Functionality: Does your application require built-in wireless connectivity (favoring ESP32)? Do you need more than one CAN interface (favoring Teensy boards with multiple CAN ports)?

-

Performance: If you expect high CAN traffic or need real-time processing alongside other tasks, Teensy’s raw clock speed may be essential.

-

Flexibility: Arduino is a strong choice for learning and simple applications. ESP32 shines when you want wireless networking and CAN in one package. Teensy excels in computationally heavy CAN applications.

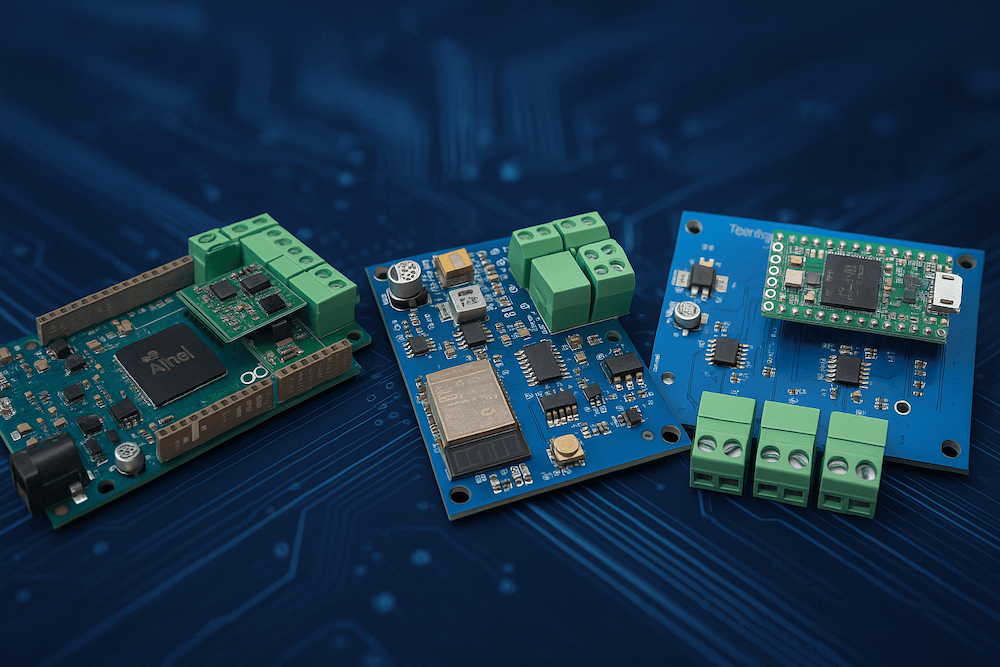

Sample Products from Copperhill Technologies

To give you a more concrete idea, here are examples of our CAN Bus development boards based on each platform:

-

Arduino: Arduino-Based ECU Development Board with Dual CAN Bus Interface

-

Teensy: Teensy 4.0 Triple CAN Bus Board with Two CAN 2.0B and One CAN FD Port

Each product reflects the strengths of its respective platform, from simplicity to performance to connectivity.

SAE J1939 Development

For developers working with SAE J1939, we recommend exploring our dedicated resource: ard1939.com. Here, you’ll find a SAE J1939 protocol stack for Arduino and ESP32.

While there is no direct release for Teensy at this time, adaptation is possible by modifying the CAN driver software—a practical solution for developers who want to take advantage of Teensy’s higher performance in J1939 applications.

Conclusion

Selecting the right platform for CAN Bus development depends on your specific application requirements and your level of experience.

-

Arduino: Best for beginners and straightforward projects.

-

Teensy: Best for high-performance applications requiring speed and multiple CAN channels.

-

ESP32: Best for applications that combine CAN Bus with wireless connectivity.

At Copperhill Technologies, we are committed to supporting all three platforms by offering ready-to-use hardware and extensive resources to help you bring your projects to life.

For Arduino enthusiasts who have already mastered the fundamentals, this book is your gateway to becoming a true expert. Through 70 advanced, hands-on projects, you’ll push the limits of the Arduino platform and develop the skills to design reliable, professional, and user-friendly systems.

You’ll learn how to:

-

Remote-control your Arduino using Bluetooth and instant messaging.

-

Enhance clock accuracy by synchronizing with internet time servers.

-

Automatically power down your Arduino when tasks are complete.

-

Safely manage AC mains power and high-current loads.

-

Conserve energy with low-power modes and sleep functions.

-

Drive LED matrix displays with Charlieplexing.

-

Ensure continuous operation using a watchdog timer.

-

Extend communication distances with RS232 and RS485 buses.

With each project, you’ll deepen your knowledge of embedded systems while building practical solutions that can be applied to real-world applications. More information...

SAE J1939 Programming with Arduino - SAE J1939 Compliance Criteria

This post is part of a series about SAE J1939 ECU Programming & Vehicle Bus Simulation with Arduino. One question that has been raised repeatedly is the one about SAE J1939 compliance. Officially, the SAE J1939-82 Standard describes the compliance tests and procedures to verify an SAE J1939 ECU will operate correctly on an SAE J1939 network. Unfortunately, the SAE J1939 [...]

Loading... Please wait...

Loading... Please wait...