Blog

Recent Posts

CAN Bus and SAE J1939: A Beginner’s Guide to Network Design

Posted by on

If you’ve ever worked with industrial machines or diesel engines, chances are you’ve heard of CAN bus and SAE J1939. These two go hand-in-hand when it comes to reliable, real-time communication between control units. Let’s break down the essentials of how these networks are designed and why they matter.

If you’ve ever worked with industrial machines or diesel engines, chances are you’ve heard of CAN bus and SAE J1939. These two go hand-in-hand when it comes to reliable, real-time communication between control units. Let’s break down the essentials of how these networks are designed and why they matter.

What Is CAN Bus?

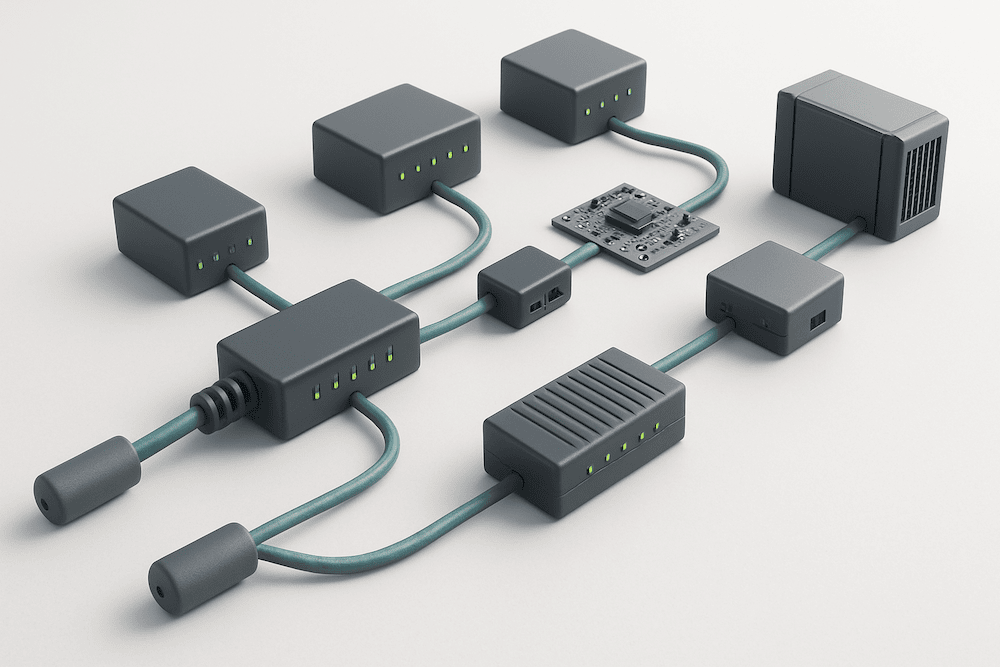

CAN (Controller Area Network) is a two-wire communication system designed to let multiple devices — or “nodes” — talk to each other without needing a central controller. It’s widely used in industrial automation, robotics, and vehicles because it’s tough, fast, and fault-tolerant.

Think of it as a shared conversation line: any device can “speak up,” but CAN ensures the most important messages always get through first.

Speed vs. Distance: Finding the Balance

When designing a CAN network, one of the first questions is: how long can my cables be at a given speed?

-

1 Mbps → up to ~40 m

-

500 kbps → ~100 m

-

250 kbps → ~250 m

-

125 kbps → up to 500 m

In other words: faster speeds mean shorter cables. If you need long runs in a factory or large machine, you’ll likely choose 250 kbps or lower.

How Many Devices Can I Connect?

Most CAN bus systems can handle around 30 nodes reliably, sometimes more depending on transceiver quality. Each device connects in parallel to the main bus line, but here’s the golden rule: keep stub connections short — ideally under 30 cm. Long stubs act like little antennas for noise and reflections.

Wiring and Termination Basics

A proper CAN network is a straight bus line, not a star or ring. At each end of the line, you’ll need a 120 Ω resistor to prevent signal reflections. With both in place, the bus should measure ~60 Ω across CAN_H and CAN_L when powered off.

For noisy environments, always go with twisted-pair cable (shielded if possible). This helps the system shrug off electromagnetic interference from motors, solenoids, and power cables.

Built-In Robustness

CAN wasn’t just built for speed — it was built for reliability. It can detect transmission errors instantly, shut down faulty nodes, and automatically retry sending messages. This is why it thrives in industrial settings where noise and electrical spikes are common.

Enter SAE J1939: Diesel’s Language of Choice

While CAN is the “wiring and signaling,” SAE J1939 is a higher-layer protocol that defines what the messages mean. It’s the standard in diesel engines, trucks, buses, agricultural machines, and construction equipment.

How J1939 Works

-

Uses 29-bit CAN identifiers to pack in priority, message type, and source address.

-

Defines Parameter Group Numbers (PGNs) for common messages like engine RPM, fuel rate, or diagnostic trouble codes.

-

Supports both broadcast messages (everyone listens) and destination-specific messages.

-

Operates typically at 250 kbps (up to 40 m cable length), with newer systems moving to 500 kbps.

Real-World Uses

-

Engine & Transmission Control: Sharing torque requests, speed, and shift information.

-

Diagnostics: ECUs report faults (DM1 messages) that technicians can read directly.

-

Fleet & Telematics: Trucks and buses stream performance data to monitoring systems.

-

Agriculture & Construction: Implements and attachments speak the same “J1939 language” as tractors and excavators.

Why It Matters

Together, CAN bus and J1939 make complex machines more reliable and easier to service. They provide a common communication backbone that keeps engines efficient, diagnostics straightforward, and equipment interoperable across manufacturers.

Whether you’re designing a factory network or plugging into a diesel truck’s diagnostic port, these standards are what make it all possible.

Takeaway: If you’re just getting started with industrial networking, remember:

-

Match your data rate to cable length.

-

Always terminate correctly.

-

Keep stubs short.

-

And if you’re working with diesel engines, learn J1939 — it’s the industry’s shared language.

For more detailed information, see our post From CAN Fundamentals to SAE J1939: Network Design for Industrial and Diesel Engine Applications...

BlueDriver Bluetooth Pro OBDII Scan Tool for iPhone & Android

BlueDriver Bluetooth Pro OBDII Scan Tool for iPhone & Android

BlueDriver is a professional-grade OBD2 scanner designed to make vehicle diagnostics simple and accessible. By plugging the Bluetooth-enabled sensor into your car’s OBDII port and connecting it to the companion app on your phone or tablet, you gain access to features once reserved for mechanics. Beyond just reading and clearing the check engine light, BlueDriver provides enhanced diagnostics that cover ABS, Airbag, SRS, TPMS, and more — letting you see a full picture of your car’s health. With live data monitoring, you can keep track of performance in real time while driving, making it more than just a code reader.

What sets BlueDriver apart is its focus on usability and value. The app offers unlimited repair reports with possible fixes, as well as step-by-step repair videos that guide you through the process. It’s fully compatible with all gas vehicles made in 1996 and later, and supports advanced diagnostics for leading brands like Ford, GM, Toyota, Honda, BMW, and more. Best of all, there are no subscription fees or hidden costs — one purchase gives you lifetime access. Coupled with 24/7 professional support via phone or in-app chat, BlueDriver ensures that you always have expert help available whenever you need it. More information...

Loading... Please wait...

Loading... Please wait...