Blog

Recent Posts

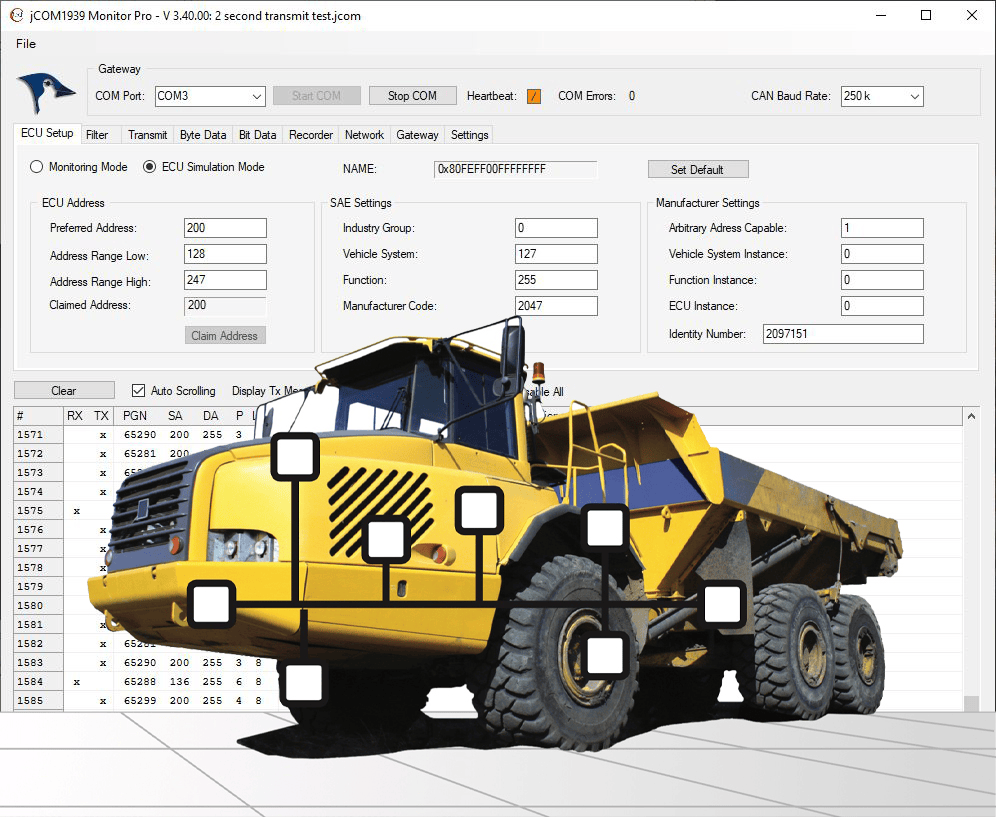

Mastering SAE J1939: Real-Time Simulation & Monitoring Made Easy

Posted by on

The SAE J1939 ECU Simulator Board by Copperhill Technologies is a high-performance, low-latency vehicle network adapter designed for SAE J1939 applications. It allows any host device with a USB COM port to monitor SAE J1939 data traffic and communicate with the SAE J1939 vehicle network. The board supports the full SAE J1939 protocol, including J1939/81 Network Management (Address Claiming), and J1939/21, including the Transport Protocol (TP). It is also supported by an extensive programming interface for Windows and Linux/Ubuntu applications, including full C/C++/C# source code for short time-to-market developments.

The SAE J1939 ECU Simulator Board by Copperhill Technologies is a high-performance, low-latency vehicle network adapter designed for SAE J1939 applications. It allows any host device with a USB COM port to monitor SAE J1939 data traffic and communicate with the SAE J1939 vehicle network. The board supports the full SAE J1939 protocol, including J1939/81 Network Management (Address Claiming), and J1939/21, including the Transport Protocol (TP). It is also supported by an extensive programming interface for Windows and Linux/Ubuntu applications, including full C/C++/C# source code for short time-to-market developments.

What Is the SAE J1939 ECU Simulator Board?

The Copperhill J1939 ECU Simulator Board is a microcontroller-based USB device that connects directly to your development PC. Acting as either a transmitter or receiver on the CAN Bus, the board simulates Electronic Control Units (ECUs) found in heavy-duty trucks, buses, and off-road machinery.

Key technical capabilities:

-

SAE J1939/21, including Transport Protocol (TP) support

-

SAE J1939/81 Network Management (Address Claim, etc.)

-

Customizable PGNs and SPNs for simulation

-

Adjustable source address and message intervals

By emulating an ECU’s behavior, this board becomes a crucial element in system integration, regression testing, or training environments.

About the JCOM1939 Monitor Software

The JCOM1939 Monitor Software is a free Windows-based GUI application designed to work out of the box with Copperhill’s J1939 hardware. With no programming required, the software allows users to:

-

Monitor incoming and outgoing CAN messages in real time

-

Configure and simulate ECU node parameters

-

Send and respond to data request PGNs

-

Visualize network load and performance

-

Export logs for analysis or debugging

The user-friendly interface is perfect for both seasoned engineers and beginners who want to explore SAE J1939 without writing complex scripts.

Use Cases: Why Developers Love This Combo

Faster Development Cycles

Avoid the need to wait for full hardware setups or actual vehicles to test your software. The simulator board lets you replicate ECU behavior instantly, enabling rapid prototyping and testing.

Data Traffic Simulation

Test how your application responds to engine speed messages (e.g., PGN 61444), vehicle position, or fuel economy data. Simulate real-world driving conditions by configuring dynamic PGN values and transmission rates.

Protocol Compliance & Debugging

Ensure that your application complies with the J1939 protocol. Use the Monitor to trace malformed PGNs, debug network collisions, and verify transport protocol behavior (RTS/CTS/BAM).

Training & Education

For training environments and technical workshops, the simulator provides a safe and visual way to teach SAE J1939 concepts without requiring access to full vehicles.

Bidirectional Communication

Simulate not only the transmission of PGNs but also the ability to respond to data requests—critical for devices like telematics units, diagnostics scanners, and gateway modules.

Real-Time Insights & Logging

Unlike traditional CAN interfaces that only stream data, the J1939 ECU Simulator and Monitor software provide structured, human-readable data tied to Parameter Group Numbers (PGNs) and Suspect Parameter Numbers (SPNs). This adds tremendous clarity during debugging and validation, especially when comparing message IDs, source addresses, or priority levels.

The system supports logging of J1939 traffic, allowing for retrospective analysis, which is ideal when trying to reproduce intermittent faults or verify time-sensitive behaviors.

How It Saves You Time (and Money)

-

✅ No need for costly full-vehicle access

-

✅ Avoids delays in hardware testing phases

-

✅ Speeds up regression testing during software updates

-

✅ Immediate feedback during application debugging

-

✅ Cuts down on steep learning curves with intuitive software

Whether you’re developing embedded systems, writing diagnostics tools, or integrating telematics solutions, the combination of Copperhill’s J1939 Simulator Board and JCOM1939 Monitor Software becomes your virtual test bench—available anytime, anywhere.

Final Thoughts

SAE J1939 development doesn’t have to be intimidating or expensive. With the Copperhill Technologies SAE J1939 ECU Simulator Board and the JCOM1939 Monitor Software, developers and engineers gain a powerful set of tools to streamline development, accelerate testing, and build better products.

Comprehensive Guide to the JCOM1939 Monitor: SAE J1939 Data Analysis, Simulation, and Hardware Integration

The JCOM1939 Monitor Software is a comprehensive Windows application developed by Copperhill Technologies, designed to monitor, record, analyze, and simulate SAE J1939 data traffic. It serves as an essential tool for professionals and enthusiasts working with Controller Area Network (CAN) protocols, particularly in heavy-duty vehicle networks. Key Features: ECU Simulation Setup: Users can configure Electronic Control Units [...]

jBoard-X2 - Hardware Installation For SAE J1939 Data Monitor, Analyzer, ECU Simulator

This post describes the installation and connection of the Copperhill SAE J1939 Data Monitor, Analyzer, ECU Simulator With jBoard-X2. This is the perfect tool to monitor, analyze, and simulate SAE J1939 data traffic. The system combines our industrial-strength jBoard-X2 that functions as an SAE J1939 to USB gateway. A comprehensive and easy-to-use, easy-to-understand Windows software displays not only [...]

Loading... Please wait...

Loading... Please wait...