Blog

Recent Posts

Industrial Ethernet Guide - Industrial Safety Networks

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Industrial safety networks utilize their own, independent hardware such as cables and sensing devices, and they function independently from the production control devices, thus allowing the smooth implementation of existing machinery regardless of their technology.

The network typically consists of a cable that allows for a quick connect or disconnect of network devices, the simple integration of new devices, easy configuration and communication between the devices, delivery of diagnostic data, plus an abundance of other, safety-contributing features. A second cable is used to supply power.

Unlike standard communications networks, safety networks are designed to tolerate errors within limits, detect when specified error limits have been reached, and react by transitioning devices to a predetermined safe state.

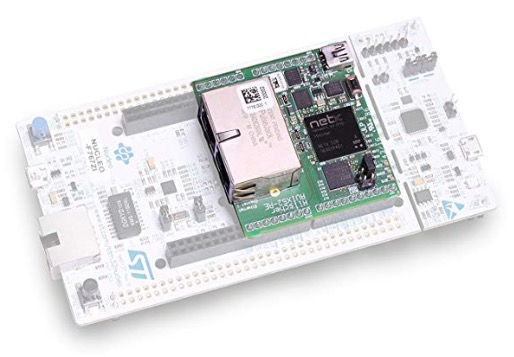

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...