Recent Posts

Miniature PCB Mountable CANopen Servo Drive For Customized Robotics Applications

Posted by on

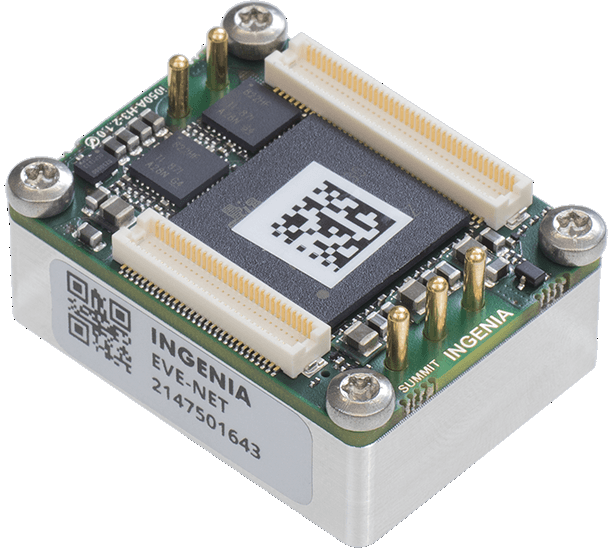

Ingenia, a member of Celera Motion (Novanta), released its Everest servo drive series with CANopen-connectivity. The Everest Core drive comes as a plug-in module, which can be integrated into a PCB (printed circuit board) in support of customized motion control applications. Everest Net drives are based on the Everest Core technology and incorporate CANopen communication.

The CANopen interface complies with CiA 301 and CiA 402 version 4.0, supporting cyclic synchronous position, cyclic synchronous velocity, cyclic synchronous current, profile position (trapezoidal and s-curves), profile velocity, interpolated position, and homing. Layer Setting Services (LSS), as specified in CiA 305, are implemented as well, allowing the configuring of the node-ID through the CAN network.

The Everest XCR servo drive module was designed in cooperation with robotics developers to integrate the module into space-limited applications. It weighs 38 g and measures 29 mm x 42 mm x 23 mm, including the mating connectors. After integration in a robotic joint or motor, the drive has to be wired and configured for operation.

The drives are suitable for brushed and brushless DC motors. The power supply can handle up to 48 VDC. Digital encoder, digital Hall sensors, Biss-C, and SSI interfaces are also available. The Motionlab configuration software comes free-of-charge with each Everest servo drive. Common applications include robot joints, wearable robots, unmanned ground vehicles, aerial vehicles, and more.

Embedded Networking with CAN and CANopen

CAN (Controller Area Network) is a serial communication protocol that was originally developed for the automobile industry. CAN is far superior to conventional serial technologies such as RS232 in regards to functionality and reliability, and yet CAN implementations are more cost-effective.

CANopen, a higher layer protocol based on CAN, provides the means to apply the ingenious CAN features to a variety of industrial-strength applications. Many users, for example, in the field of medical engineering, opted for CANopen because they have to meet particularly stringent safety requirements. Similar requirements had to be considered by manufacturers of other equipment with very high safety or reliability requirements (e.g., robots, lifts, and transportation systems).

Providing a detailed look at both CAN and CANopen, this book, written by the founders of the Embedded Systems Academy, examines those technologies in the context of embedded networks. There is an overview of general embedded networking and an introduction to the primary functionality provided by CANopen.

Everything one needs to know to configure and operate a CANopen network using off-the-shelf components is described, along with details for those designers who want to build their CANopen nodes. The wide variety of applications for CAN and CANopen is discussed, and instructions in developing embedded networks based on the protocol are included. Also, references and examples using MicroCANopen, PCANopen Magic, and Vector's high-end development tools are provided.

Loading... Please wait...

Loading... Please wait...