Recent Posts

Industrial Ethernet Guide - Topology and Communication Features

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

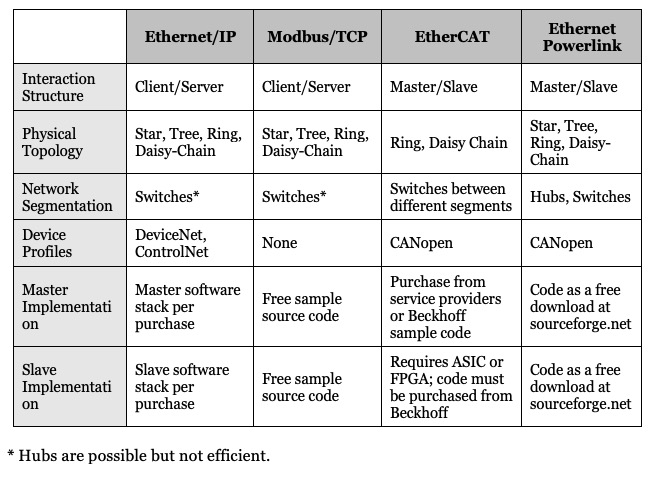

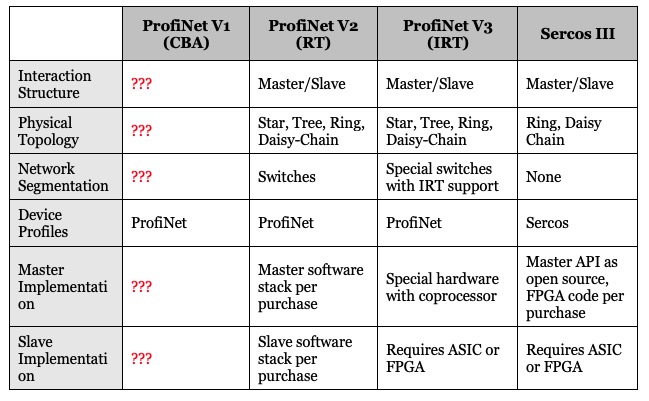

The following information has been compiled with the best of intentions. However, as I have pointed out frequently, a fair and complete comparison of Industrial Ethernet Protocols is challenging.

Furthermore, specifications and organizational features may have changed since the time of this writing.

I have marked some parameters in red, indicating that the information was either not available or may not be entirely correct (This is especially true regarding the Profinet protocol; Siemens maintains their reputation of providing complex technologies with cryptic documentation).

Please feel free to contact me in case you find an error or when clarification is needed.

While communication mechanisms are specified for Sercos III and EtherCAT, the inner workings of their slaves remain undisclosed. Users must resort to an ASIC or an FPGA. FPGA IP code from Beckhoff is available for EtherCAT as object code; the source code is not disclosed.

Note: Ethernet switches add latency per message to a network (According to current technology 7.5 microseconds in the best case; more than 10 microseconds are standard). The impact on the cycle time depends on the network load. In all consequence, Ethernet switches are disadvantageous when it comes to achieving hard real-time performance.

The impact of hubs on the cycle time is minimal (~ 500 nanoseconds).

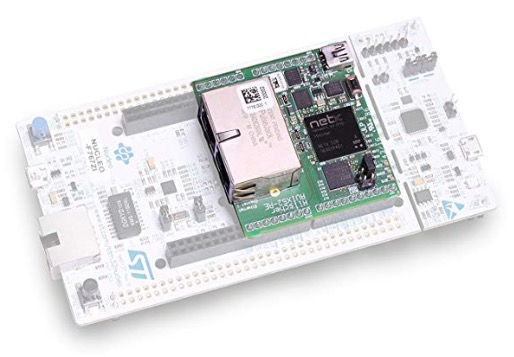

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...