Recent Posts

Industrial Ethernet Guide - Industrial Ethernet Protocols

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Note: It is important to re-iterate the point that a sufficiently detailed description of each protocol involved is clearly outside the scope of this book. Complete documents are provided by the respective manufacturers or standardization/user organizations, even though they usually provide little educational value, and some of these standards are only available to the organizations’ members. The intended purpose of this book is to deliver a convenient entry to understanding the topic.

The unpredictable nature of Ethernet TCP/IP’s timing has long been a drawback for many industrial network applications, specifically those with stringent real-time capability requirements. As the overall cost vs. benefit performance has improved over time, industrial users have developed methods to overcome the apparent shortcomings.

The implementation of additional Real-Time Data Exchange protocol layers (i.e., add-on software) incorporated prioritization, synchronization, and other techniques to ensure the timely delivery of messages. Besides, Industrial Ethernet solutions rely to various degrees on the modification of the physical and data link layer, may it be through using switches and hubs in the network or even dedicated Ethernet controllers.

In total, there are currently about thirty Industrial Ethernet systems in use around the world, but those currently most significant for the industry are:

- Ethernet/IP

- Modbus/TCP

- EtherCAT®

- Ethernet Powerlink

- ProfiNet

- Sercos III

The selection is based on technical aspects, standardization status, and strategic market considerations.

Another critical aspect was market penetration. Various surveys indicate that about three-quarters of all Industrial Ethernet application around the world use Ethernet/IP, ProfiNet, or Modbus/TCP, followed by Ethernet Powerlink and EtherCAT®.

Modbus/TCP was included due to its status as the oldest Industrial Ethernet protocol, even though it has now been incorporated into Ethernet/IP.

Sercos III, specifically designed to support fast motion control applications, was included for comparison despite its marginal market share.

All these protocols have been developed with the challenges of real-time control in mind (constant cycle times, low latency, low jitter), specifically the design of preventive measures to avoid data collisions, and they approached the solution in different ways.

As the following chapter will explain, an appropriate classification of Industrial Ethernet protocols is virtually an impossible task. It is, however, fair to state that protocols such as Modbus/TCP and Ethernet/IP face the most significant challenges when it comes to achieving hard real-time control. Nevertheless, these two variants of Industrial Ethernet own the largest global market share in terms of installed Industrial Ethernet nodes.

All other protocols have been developed with the demands of real-time control in mind (constant cycle times, low latency, low jitter), specifically the design of preventive measures to avoid data collisions, and they approached the solution in different ways.

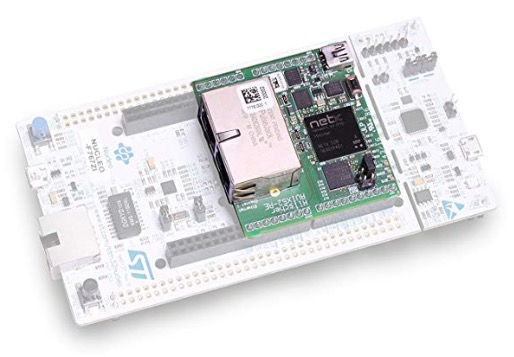

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...