Recent Posts

Engineering Note: Reverse Engineering Of CAN Bus Communication

Posted by on

There are many applications, in which one may need to reverse engineer CAN Bus communication. Examples are automotive competitor analysis, telematics applications such as fleet management, and disabled driver applications.

The typical reverse engineering process is concerned with moving a sensor and watching the CAN Bus network for message changes. For example, wind down a door window and see if this kicks-off changes in CAN Bus frame data fields. Many CAN Bus networks have multiple frames originating from many ECUs (electronic control units), which means it is difficult to watch all data simultaneously. It would be more comfortable if one could watch a smaller number of CAN Bus data frames to observe changes by isolating the origin, i.e., the ECU sending these frames.

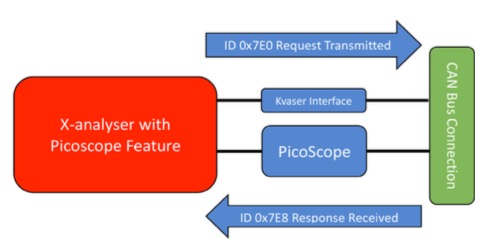

This engineering note describes a process that allows the user to identify particular ECUs transmitting CAN Bus data frames. This is achieved by getting the electrical signature of each CAN data frame and matching known frames with the unknown. Consequently, the transmitting ECU of the unknown CAN Bus data frame can be determined.

Read the Warwick Control Technologies Engineering Note (PDF)...

Dual CAN Bus Interface For Arduino Due With Extended Power Range

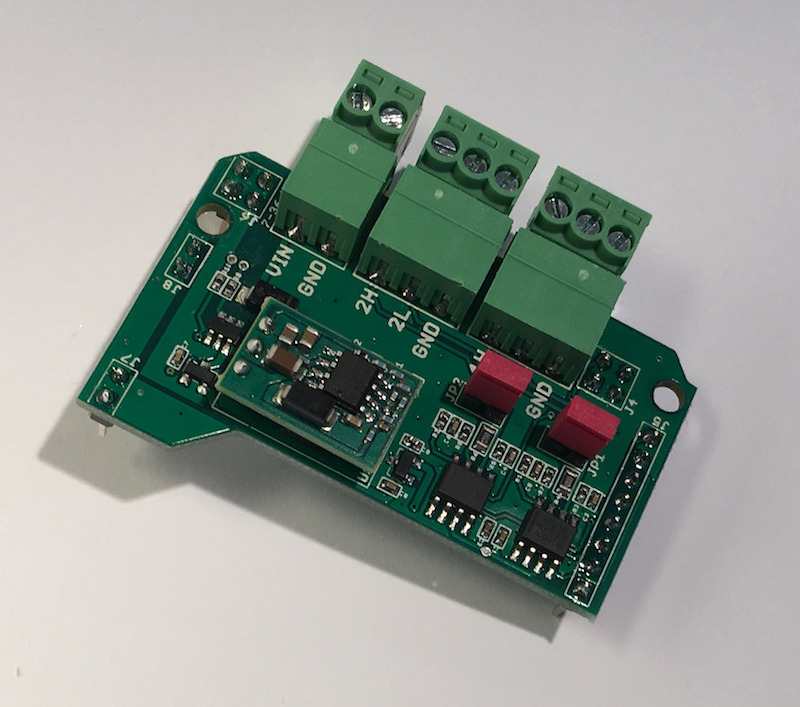

The jCOM.CAN.DUE-X, a dual CAN bus interface for the Arduino Due, is not an Arduino shield in the common sense.

The board incorporates dual CAN transceivers required by the two integrated CAN ports on the Arduino Due while allowing the operation with any Arduino-compatible shield that supports the necessary 3.3 VDC power requirements.

By combining our dual CAN port interface, the Arduino DUE microcontroller, an OBD2 or SAE J1939 cable, and open-source software libraries you are ready to go with powerful a turn-key Arduino-based dual CAN bus solution.

Leverage the 32-bit processing capability of the Arduino DUE plus the built-in CAN ports for your next prototype.

In order to more efficiently serve automotive and industrial applications, the jCOM.CAN.DUE-X board supports an extended input power range of 7 to 36 VDC to power the entire system, i.e. including the Arduino Due itself.

Loading... Please wait...

Loading... Please wait...