Recent Posts

CAN Bus Applications in Medical Devices: Precision Communication in Critical Environments

Posted by on

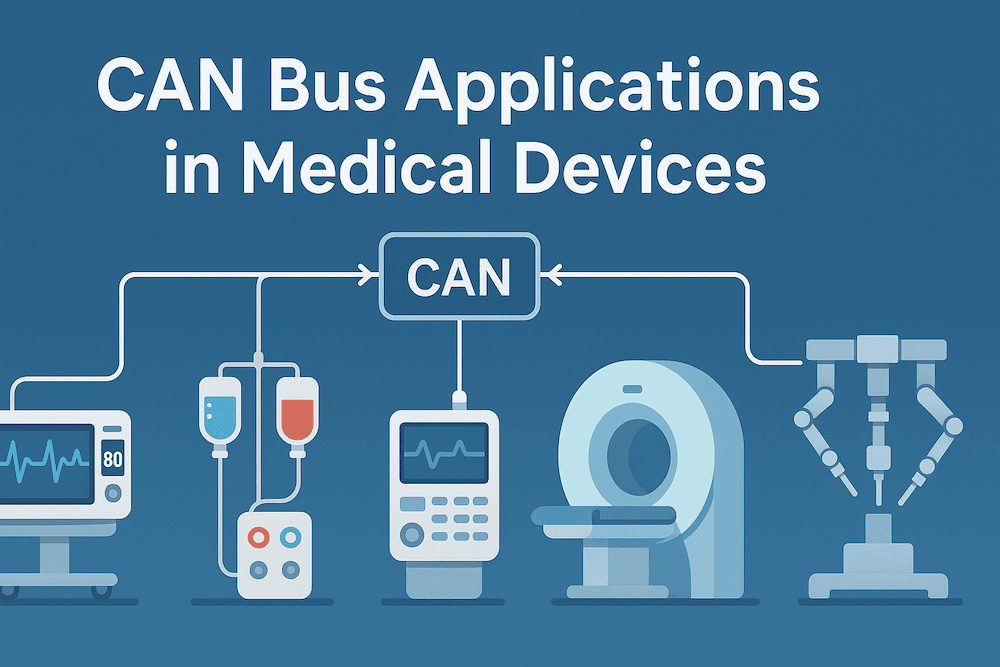

When most engineers think of Controller Area Network (CAN) Bus, their minds often go to automotive applications—after all, it was originally developed by Bosch for in-vehicle networking. However, CAN Bus has quietly become a powerful tool beyond the automotive world, particularly in the medical field. From hospital equipment to patient monitoring systems, CAN Bus technology plays an increasingly vital role in ensuring reliable and deterministic data communication in life-critical applications.

When most engineers think of Controller Area Network (CAN) Bus, their minds often go to automotive applications—after all, it was originally developed by Bosch for in-vehicle networking. However, CAN Bus has quietly become a powerful tool beyond the automotive world, particularly in the medical field. From hospital equipment to patient monitoring systems, CAN Bus technology plays an increasingly vital role in ensuring reliable and deterministic data communication in life-critical applications.

Why Use CAN Bus in Medical Devices?

In medical environments, system reliability and fault tolerance aren’t just technical specifications—they can be matters of life and death. CAN Bus stands out among communication protocols for several reasons:

-

High Reliability and Fault Tolerance:

CAN was designed to handle harsh electrical environments, making it naturally robust against electromagnetic interference (EMI), which is common in hospital settings filled with electronic equipment. -

Real-Time Capabilities:

CAN Bus supports real-time communication through message prioritization. Messages with higher priority IDs can take precedence on the bus, a key requirement in systems where response time is critical. -

Error Detection and Recovery:

CAN includes powerful error detection and confinement mechanisms, such as cyclic redundancy checks (CRC), bit monitoring, and automatic retransmission. This helps ensure communication integrity, a must in medical diagnostics and treatment equipment. -

Scalability and Interoperability:

With its multi-master architecture, CAN allows multiple devices (or “nodes”) to communicate without a central host, which is useful in modular medical systems. Devices can be added or removed without the entire system needing reconfiguration. -

Low Power Requirements:

Many portable and battery-powered medical devices benefit from CAN Bus’s low power consumption compared to Ethernet or other higher-bandwidth systems.

Real-World Applications of CAN Bus in Medical Devices

Let’s explore some specific examples where CAN Bus is deployed in the medical industry:

1. Patient Monitoring Systems

Hospitals often use centralized monitoring systems to track patients’ vital signs (ECG, blood pressure, oxygen saturation, etc.). CAN Bus allows multiple sensor modules to transmit data to a central processor in real time with deterministic performance. This ensures accurate and synchronized readings, which are critical during surgery or intensive care.

2. Dialysis Machines

Hemodialysis machines rely on tightly controlled feedback loops to regulate blood flow, monitor toxin levels, and manage fluid balances. CAN Bus connects different subsystems, such as blood pumps, sensors, and filtration units, enabling precise coordination.

3. Infusion Pumps

Infusion therapy demands precise delivery of fluids and medications. In advanced infusion pump systems, CAN Bus connects multiple channels to a central control module, ensuring that dosage information is synchronized and that any fault conditions are detected and reported immediately.

4. Imaging Equipment (e.g., MRI and CT Scanners)

CAN Bus is used to coordinate various mechanical and diagnostic subsystems within imaging machines. It ensures that data from position sensors, cooling systems, and gantry controllers are communicated quickly and reliably.

5. Surgical Robots

Robotic-assisted surgery systems use CAN Bus to coordinate actuators, force sensors, and haptic feedback devices. Because of its real-time nature and high fault tolerance, CAN Bus ensures synchronized operation of components, allowing for precise movements and safer patient outcomes.

6. Ventilators and Respiratory Systems

CAN networks are used to link control systems, pressure sensors, and flow valves in ventilators. These systems require continuous feedback and rapid response to changes in a patient’s breathing, which CAN handles efficiently.

The Growing Role of CAN FD in Medical Devices

While classical CAN (up to 1 Mbps) remains widely used, newer medical devices are beginning to adopt CAN FD (Flexible Data Rate), which supports faster data rates and larger payloads. This is particularly valuable in devices that require more bandwidth but still benefit from CAN’s robust error-handling and deterministic behavior.

For example, a surgical robot equipped with multiple high-resolution sensors can benefit from CAN FD’s extended data frame (up to 64 bytes), reducing bus load and increasing performance without sacrificing reliability.

Conclusion

As medical devices become increasingly complex, the demand for reliable, real-time, and fault-tolerant communication protocols continues to grow. CAN Bus—originally developed for automobiles—has proven itself as a powerful backbone for critical medical applications. Its ability to manage communication across diverse devices while ensuring safety and reliability makes it an ideal choice in healthcare environments where failure is not an option.

Whether it’s regulating dialysis, managing respiratory systems, or aiding in robotic surgery, CAN Bus technology is quietly saving lives—one frame at a time.

References & Further Reading

Accelerate CAN Bus Prototyping with Teensy-Based Solutions from Copperhill Technologies

Accelerate CAN Bus Prototyping with Teensy-Based Solutions from Copperhill Technologies

Prototyping with CAN Bus has never been easier or more powerful than with the Teensy-based solutions offered at Copperhill Technologies. Whether you're building automotive, industrial, or medical device applications, Teensy boards provide a compact and cost-effective platform for rapid development. Combined with integrated CAN FD support and high-performance ARM Cortex-M microcontrollers, these tools give engineers the flexibility and speed they need to test, iterate, and refine CAN-based systems with precision and confidence.

Copperhill’s Teensy CAN Bus products come equipped with advanced features such as dual CAN ports, optional galvanic isolation, and compatibility with Arduino and NXP software environments. Developers can tap into powerful libraries, real-time debugging capabilities, and extensive community support. From building diagnostic tools to simulating ECU behavior or developing complete CAN-based networks, these Teensy boards enable fast, efficient, and scalable CAN Bus prototyping—accelerating your path from concept to deployment. More information...

Loading... Please wait...

Loading... Please wait...