Blog

Recent Posts

Raspberry Pi and PiCAN-M in Marine NMEA 2000 Systems: Power Supply Considerations

Posted by on

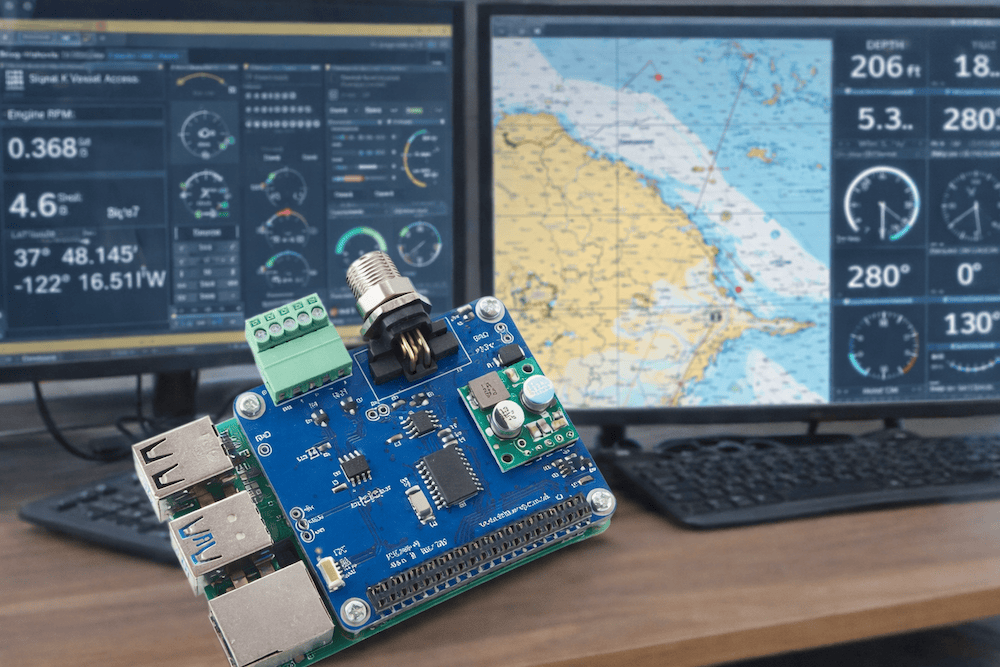

Single-board computers based on the Raspberry Pi have become common building blocks in modern marine electronics. When combined with PiCAN-M, they are frequently used as onboard data gateways for applications such as Signal K and OpenPlotter, translating NMEA 2000 traffic into IP-based data streams, dashboards, and logs.

Single-board computers based on the Raspberry Pi have become common building blocks in modern marine electronics. When combined with PiCAN-M, they are frequently used as onboard data gateways for applications such as Signal K and OpenPlotter, translating NMEA 2000 traffic into IP-based data streams, dashboards, and logs.

In practice, most field issues reported in these systems are not related to CAN communication itself, but to power budgeting and power stability, especially when the Raspberry Pi is powered directly from the NMEA 2000 backbone.

This article explains how Raspberry Pi power requirements differ across versions 3, 4, and 5, how those requirements interact with the NMEA 2000 power model, and how the PiCAN-M variants with and without onboard SMPS should be used in each case.

NMEA 2000 Power Model in Brief

NMEA 2000 is designed around a shared network power concept. Devices are powered from the backbone and are budgeted using Load Equivalency Numbers (LEN), where 1 LEN corresponds to 50 mA at nominal network voltage.

In real installations, the following assumptions are common:

-

Backbone power is nominally 12 VDC (with an allowed operating range).

-

Total backbone current is typically limited to about 3 A by cabling, fusing, and installation practice.

-

Devices drawing more than approximately 1 A equivalent are normally expected to be powered separately, even if they remain connected to the network for data.

This model works very well for sensors, displays, gateways, and control units that draw modest and predictable current. It is not well suited to powering general-purpose computers.

Raspberry Pi Power Requirements by Generation

The Raspberry Pi family spans multiple performance classes. While they share a 5 V input requirement, their current demand and transient behavior differ significantly.

Raspberry Pi 3

Raspberry Pi 3 models are specified for a 5 V supply rated at approximately 2.5 A.

In marine gateway applications (Signal K, OpenPlotter, logging, light dashboards), the Pi 3 typically operates comfortably within this envelope. Peak current events exist, but they are relatively modest.

From a power perspective, the Raspberry Pi 3 is generally compatible with small, well-designed DC/DC converters.

Raspberry Pi 4

Raspberry Pi 4 models increase CPU performance, memory bandwidth, and I/O capability. The recommended supply rating increases to 5 V at 3 A.

In steady operation, a Pi 4 used as a marine gateway often runs below this limit, but transient peaks become more significant, particularly during:

-

boot

-

CPU bursts

-

Wi-Fi activity

-

SD card writes

This places the Pi 4 at the upper edge of what a 5 V / 3 A rail can reliably support.

Raspberry Pi 5

Raspberry Pi 5 represents a major architectural jump. It is specified for a 5 V supply rated up to 5 A.

Even when no USB SSDs or high-power peripherals are attached, the Pi 5 can draw substantially more current than previous generations due to higher CPU performance, I/O bandwidth, and power management behavior.

A 5 V / 3 A supply is sufficient only in a restricted mode and leaves little margin for transient load events.

From a marine power-distribution perspective, Raspberry Pi 5 must be treated as a computer-class load, not as a typical embedded device.

Translating 5 V Raspberry Pi Loads to NMEA 2000 Backbone Current

When a Raspberry Pi is powered from the NMEA 2000 backbone, the 12 V network power must be converted to 5 V using a switch-mode power supply (SMPS).

This conversion matters.

Approximate power relationships:

-

Raspberry Pi 3:

5 V × 2.5 A ≈ 12.5 W → roughly 1.1–1.3 A from the 12 V side -

Raspberry Pi 4:

5 V × 3 A ≈ 15 W → roughly 1.4–1.6 A from the 12 V side -

Raspberry Pi 5:

5 V × 5 A ≈ 25 W → roughly 2.3–2.7 A from the 12 V side

These values assume reasonable SMPS efficiency and do not include additional margin for transient load spikes.

In a network commonly constrained to about 3 A total, a Raspberry Pi 5 alone can consume most of the entire backbone power budget.

PiCAN-M Variants and Power Behavior

The PiCAN-M by Copperhill Technologies is a compact and robust CAN bus interface designed specifically for Raspberry Pi systems used in marine and industrial applications. It provides a direct hardware connection to NMEA 2000 and other CAN-based networks, enabling reliable reception and transmission of CAN frames for software platforms such as Signal K and OpenPlotter. PiCAN-M integrates seamlessly with the Raspberry Pi ecosystem, offering stable CAN communication, galvanic isolation options depending on variant, and versions with or without an onboard 12 V to 5 V switch-mode power supply, allowing flexible integration into a wide range of power architectures. Designed with real-world installations in mind, PiCAN-M is widely used as a dependable gateway between modern IP-based systems and CAN-based marine networks.

The PiCAN-M is available in variants with and without an onboard SMPS.

PiCAN-M with onboard SMPS (NMEA-powered)

This variant includes a 12 V → 5 V switch-mode power supply rated for 5 V at 3 A. The SMPS draws its input power directly from the NMEA 2000 network.

Behavior by Raspberry Pi version:

-

Raspberry Pi 3

Generally suitable. The SMPS provides adequate current, and the resulting backbone load is usually acceptable in lightly to moderately loaded networks. -

Raspberry Pi 4

Typically functional but operating at the limit. System stability depends heavily on backbone wiring quality, total network load, and transient behavior. Marginal installations may exhibit occasional undervoltage symptoms. -

Raspberry Pi 5

Not suitable. The 5 V / 3 A limit is below the Pi 5’s specified requirement, and the corresponding 12 V backbone current approaches or exceeds what many networks can reliably supply. Undervoltage warnings, reboots, or intermittent behavior should be expected.

PiCAN-M without onboard SMPS (externally powered Raspberry Pi)

In this configuration, the Raspberry Pi is powered independently, and PiCAN-M interfaces only to the CAN bus.

Behavior by Raspberry Pi version:

-

Raspberry Pi 3

Fully supported with a dedicated 5 V / 2.5 A supply or equivalent DC/DC converter. -

Raspberry Pi 4

Fully supported with a dedicated 5 V / 3 A supply. -

Raspberry Pi 5

Strongly recommended approach. A dedicated 5 V / 5 A-class supply provides the required headroom and isolates the NMEA 2000 network from computer-class power demand.

This configuration aligns best with NMEA 2000 power-budget assumptions and results in the highest system reliability.

Typical Failure Patterns Caused by Marginal Power

When Raspberry Pi power is undersized or drawn from an overstressed backbone, the symptoms are often indirect:

-

spontaneous reboots under load

-

SD card filesystem corruption over time

-

intermittent disappearance of NMEA 2000 devices

-

unstable Wi-Fi or delayed startup

-

undervoltage warnings logged by the operating system

These issues are frequently misattributed to software or CAN communication problems, when the root cause is power integrity.

Practical Guidance for Marine Installations

-

Raspberry Pi 3 and Raspberry Pi 4 can be used with PiCAN-M SMPS variants in suitable networks, provided total backbone load is well understood.

-

Raspberry Pi 5 should be powered from a dedicated supply and not from NMEA 2000 backbone power.

-

Treat NMEA 2000 power as a network-device resource, not as a general 5 V power rail.

-

Separating computing loads from network power improves stability, simplifies troubleshooting, and aligns with established marine installation practice.

Modern marine electronics rely on NMEA 2000, a standardized CAN-based network that allows engines, sensors, displays, navigation systems, and monitoring devices to communicate over a single, shared backbone. Instead of point-to-point wiring, NMEA 2000 uses a robust two-wire CAN bus to distribute data efficiently and reliably across the vessel. While powerful and flexible, this technology often appears intimidating due to unfamiliar terminology, strict wiring rules, and a lack of clear beginner-level explanations.

Many boat owners, technicians, and engineers struggle to understand how CAN Bus and NMEA 2000 systems actually work in practice. Confusing diagrams, fragmented documentation, and overly theoretical explanations make it difficult to build or troubleshoot a network with confidence. That is exactly why First Steps in CAN Bus with NMEA 2000 was written. This book provides a beginner-friendly yet technically accurate path to understanding, designing, and maintaining NMEA 2000 networks without requiring prior CAN experience.

Whether you are new to marine electronics or looking to strengthen your foundation before moving on to advanced configurations, this guide walks you through every critical concept step by step. It explains how CAN communication works, how NMEA 2000 builds on it, and how real devices share data on the network. Rather than acting as a dry reference manual, the book emphasizes practical understanding through real-world examples, clear diagrams, and straightforward explanations.

Inside the book, you will learn how to design a stable network using correct cabling and termination practices, manage power and grounding to avoid common failures, understand PGNs and data flow, and safely integrate displays, sensors, GPS units, and engine gateways. Dedicated chapters focus on troubleshooting and testing, showing how to diagnose voltage issues, communication errors, and network load problems using practical methods that reflect real installations.

Written with field-tested experience and a clear, professional voice, First Steps in CAN Bus with NMEA 2000 turns a complex marine communication standard into something practical and approachable. It gives you the knowledge and confidence to design, install, and maintain reliable NMEA 2000 networks, helping your systems perform as intended and saving time, frustration, and costly mistakes along the way. More information...

Essential Resources for NMEA 2000 Development with ESP32

This blog post is intended to highlight additional, practical resources that can significantly improve the development workflow for NMEA 2000 devices based on the ESP32 processor. Once the fundamentals of CAN bus and NMEA 2000 are understood, progress often depends on having the right reference material and the right diagnostic tools. The following resources address [...]

NMEA 2000 Explained: A Practical Guide to CAN Bus Marine Networking

Modern marine electronics rely on NMEA 2000, a standardized CAN-based network that allows engines, sensors, displays, navigation systems, and monitoring devices to communicate over a single, shared backbone. Instead of point-to-point wiring, NMEA 2000 uses a robust two-wire CAN bus to distribute data efficiently and reliably across the vessel. While powerful and flexible, this technology [...]

ESP32 NMEA 2000 Sensor Integration: Qwiic I2C Sensors for Marine Applications

The ESP32S3 CAN‑Bus Board with NMEA2000 Connector by Copperhill Technologies is a compact, high-performance development board based on the dual-core ESP32-S3-WROOM-1 microcontroller with integrated Wi-Fi and Bluetooth connectivity. Designed expressly for embedded and marine applications, it includes 8 MB of PSRAM and 8 MB of flash, a USB-C port for power and programming, RGB status [...]

Why the PiCAN-M with SMPS Cannot Power Raspberry Pi 5 — and the Simple Workaround

The PiCAN-M HAT from Copperhill Technologies is a specialized interface developed exclusively for marine applications and specifically targets NMEA 2000 networks. NMEA 2000 is the standard backbone for modern marine electronics, used to interconnect engines, chart plotters, sensors, and onboard monitoring systems. In its standard version without SMPS, the PiCAN-M HAT is powered directly from [...]

MicroPython on ESP32: Beginner's Guide to Programming, Setup, and IoT Project Basics

MicroPython is a lean re-implementation of Python 3 designed for microcontrollers. It provides an interactive REPL(Read-Evaluate-Print Loop) and supports a large subset of the Python standard library, making embedded programming more accessible to those familiar with Python. In simple terms, MicroPython lets you write Python code to control hardware like the ESP32 without the need [...]

Local Interconnect Network (LIN) in Automotive: A Beginner’s Guide

The Local Interconnect Network (LIN) is a low-cost, low-speed serial bus system used in modern vehicles to communicate between electronic components. It was introduced as a complement to the faster Controller Area Network (CAN) bus, targeting applications where high performance isn’t needed and cost is critical. LIN operates over a single wire (plus ground) at [...]

Why CAN and LIN Need to Communicate in Modern Vehicles

At first glance, it may seem odd that a vehicle would use two different network technologies—CAN (Controller Area Network) and LIN (Local Interconnect Network)—and even stranger that they need to communicate with each other. After all, why not use one network everywhere and avoid the complexity? The truth is that both CAN and LIN exist because [...]

CAN Bus Programming in Python for Automotive, Industrial Automation, and Robotics

The Controller Area Network (CAN bus) is a resilient, lightweight, and efficient communication protocol originally developed by Bosch in the 1980s for in-vehicle networks. It allows multiple microcontrollers (ECUs) and devices to communicate without a central host, using a multi-master, message-oriented design. Over the decades, CAN bus has expanded beyond its automotive roots into domains [...]

Mastering CAN Bus: Essential Guide to Understanding and Troubleshooting Vehicle Networks

In today’s world of connected vehicles and industrial automation, understanding the details of networked communication protocols has become a pivotal skill for engineers and technicians alike. The book Mastering CAN Scratch: Understanding & Troubleshooting (ISBN/ASIN B0G24Z25RZ) steps into this space by offering a comprehensive, hands-on guide to the widely used Controller Area Network (CAN) bus [...]

Loading... Please wait...

Loading... Please wait...