Recent Posts

Industrial Ethernet Guide - The Ethernet Technology Plant Of The Future

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Besides its definite technological advantages for automation and control tasks, Industrial Ethernet offers new perspectives for the manufacturing process that were not possible with other, established industrial networking technologies.

For the longest time, access to existing production information was gated by disparate, proprietary, and closed systems.

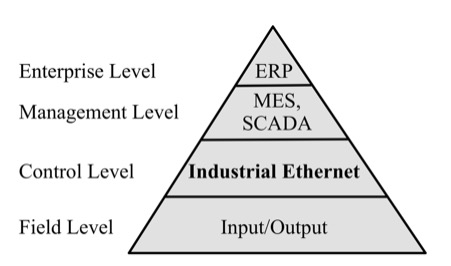

In general, the increased performance Industrial Ethernet protocols and their devices, compared to older technologies, break with the traditional view of the automation pyramid as shown below.

“Smarter” input and output devices blur the line between the Field and Control Level, while the capabilities of the various Industrial Ethernet protocols can reach into the Management level through connecting directly to the manufacturer’s LAN or Intranet.

Automation Pyramid

Although most manufacturers recognized that the standard Ethernet TCP/IP held the potential of being the networking standard in the manufacturing environment, only a few adopted Ethernet for industrial automation.

Much of the resistance to migration is based on the aversion to disrupting existing systems, the accounting realities of fully depreciated assets, and the general fluctuation of production investment cycles.

Besides, the market was serviced to a certain degree by small niche vendors with narrowly designed products or limited support capabilities.

This situation has changed with more prominent players entering the market, who recognized the need for industrial networking standards.

An increasing number of manufacturers today embrace the use of Industrial Ethernet to broaden the range of plant floor applications. Industrial Ethernet, with its continued support for standard Ethernet TCP/IP, allows them to install a standardized network throughout the manufacturing facility, from office to plant floor, addressing the needs for engineers in automation and control as well as in information technology.

The main business pressures are:

- Need to reduce the costs of manufacturing operations

- Need to improve the responsiveness to the demands of customers and the global supply chain

- Improve the visibility into manufacturing data

- Need to consolidate disparate networks

- Allow existing network infrastructure to support new applications

Faced with the pressure of cutting costs through increased efficiency and the demand for better products and services, manufacturers realized the benefits of a converged network.

These benefits are:

- Greater visibility

- Better data integration

- Shorter lead times

- Increased turnaround

- Reduced costs

- Simplified management

The efficiency of the manufacturing process can be significantly streamlined when the information contained in automation and control systems is available and shared throughout the larger enterprise. Standard communication and uniform networking of industrial systems, as provided by Industrial Ethernet, is the key to optimized services, greater visibility, and lower cost of ownership.

Consequently, regardless of their nature, all of the control and automation systems on the plant floor must interact in real-time with the enterprise applications, supply chain partners, and end customers. To accomplish that, manufacturers are bringing their industrial automation systems online.

Industrial Ethernet achieves the real-time communication requirements needed for determinism as well as the reliability and resiliency required by industrial applications. Besides, it provides standard network services to the applications and integrates them into a broader enterprise network.

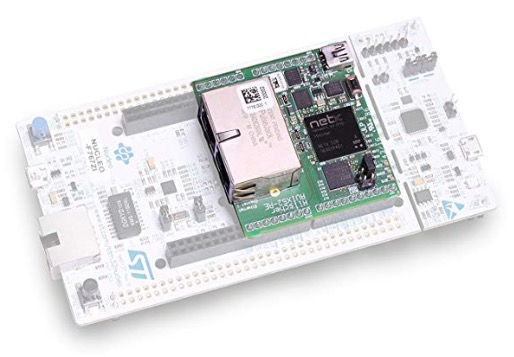

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...