Recent Posts

Industrial Ethernet Guide - The Black Channel Principle

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Safety protocols for Industrial Ethernet operate only on the topmost (application) layer of a network, where safety data is communicated independent of particular network characteristics that may differ from one underlying bus system to another. This approach is commonly known as Black Channel Operation in communication protocol engineering.

While separate safety networks utilize their independent cabling, the Black Channel Principle allows the exchanging of safety-relevant data and diagnostic information through existing network connections and, as a result, enables faster responses. The combined benefits of this method contribute to maximized productivity of the manufacturing process, and they reduce downtime.

Under the Black Channel Principle, failsafe and standard data are transmitted through the same network, but safety components transmit data using an isolated safety data transmission protocol.

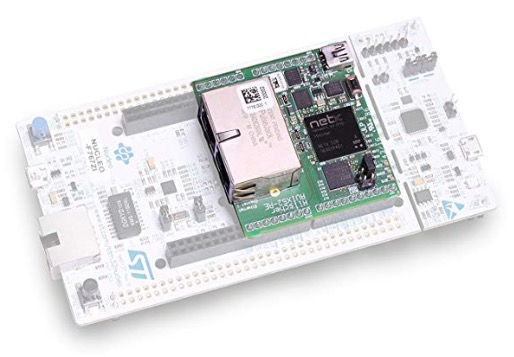

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...