Recent Posts

Industrial Ethernet Guide - Safety Functionality

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Over the years, the safety of production environments has become a focus for machine and plant manufacturers, mainly since the requirements for safety have grown to be considerably demanding (e.g., the 2006/42/EC Machinery Directive by the European Union). Manufacturers are more than ever required to design solutions that provide protection of workers against bodily harm and protect machinery against damage while maintaining a high level of productivity.

The innovative process of meeting these safety demands, combined with the emergence of new technologies such as Industrial Ethernet with its enormous potential of effective responses, significantly changed the approach toward the design of safety solutions.

Traditional safety equipment used to be hard-wired using dedicated switching circuitry such as an emergency switch, thus limiting the logic to hardware whose only reaction to safety violations resulted in the immediate halt of the entire machine. While this method, combined with some efforts and ingenuity, may cover the majority of safety-compromising scenarios, engineers in the industry recognized the benefits of integrated safety.

Integrated safety is achieved through the use of safe, programmable control hardware and I/O modules using existing Fieldbus technologies, for instance, Industrial Ethernet, to exchange safety-relevant data, and their applications are based on standardized, safety-certified software.

Network-integrated safety systems represent a substantial advantage over hard-wired solutions, similar to the advantages of distributed over central control:

- Increased flexibility due to logic programming

- Lower number of components and reduced wiring, thus lowering the system costs

- Simplified error diagnostics

- Faster error recovery

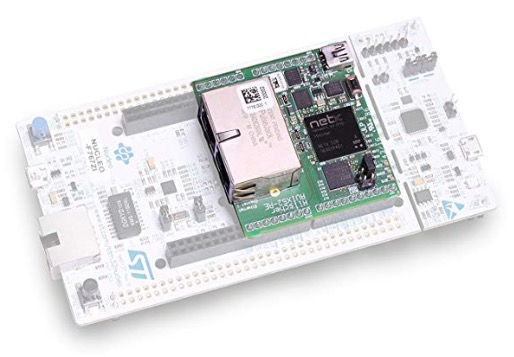

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...