Recent Posts

Industrial Ethernet Guide - Determinacy and Real-Time Control (The Hunt for CSMA/CD)

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Any solution attempting to achieve true determinacy and real-time control based on Ethernet TCP/IP requires the elimination of the CSMA/CD, IP, and UDP components, because their combined characteristics contribute to unpredictable cycle times and additional jitter.

CSMA/CD can be easily eliminated through the use of full-duplex Ethernet switches, while the exclusion of the UDP/IP components can be achieved through a modification of the TCP/IP Link Layer (dedicated hardware) or bypassing the TCP/IP/UDP protocols (add-on software). There are, however, solutions that still deal with the UDP/IP jitter issue, and their real-time performance is limited.

Note: The following categorizes the individual protocols in three groups of functionalities. There is no direct correlation to the classification based on data transfer times (as described in the previous chapter).

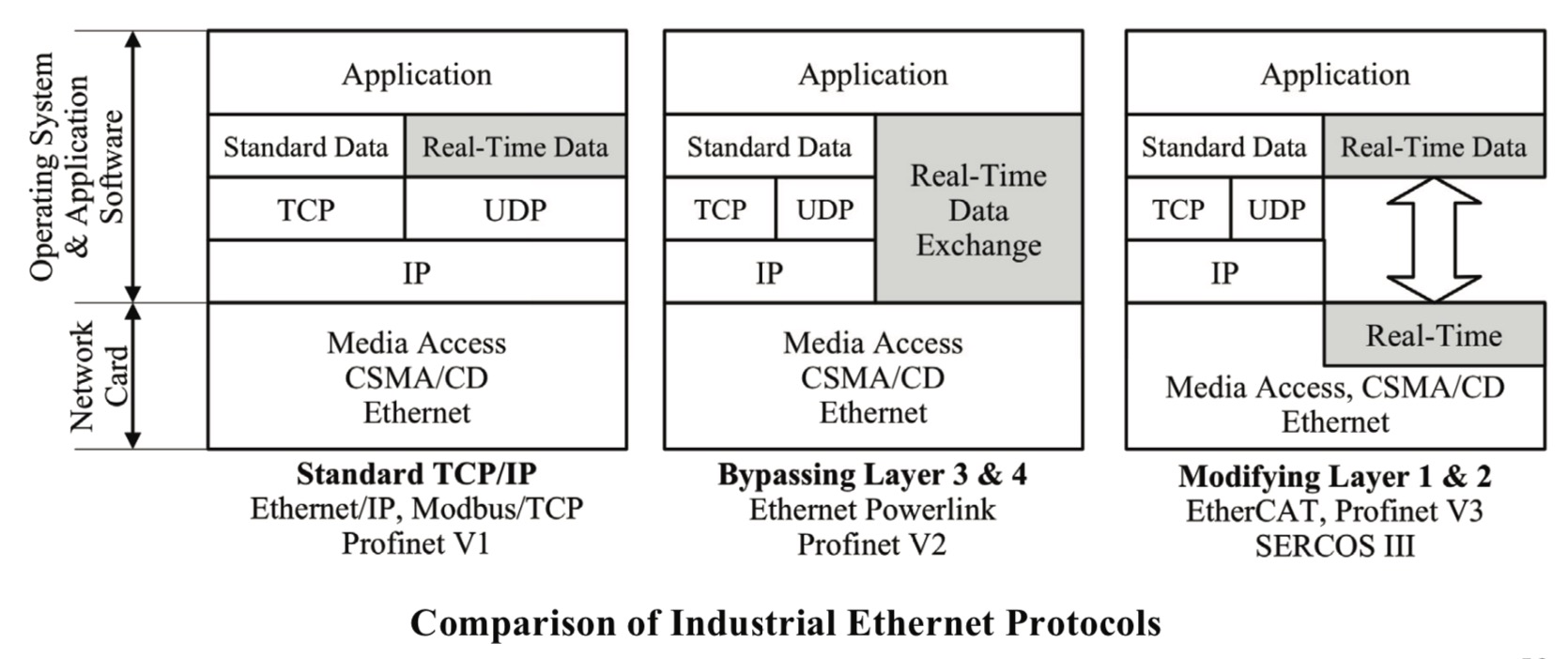

There are three different approaches to achieve Real-Time Industrial Ethernet:

- Based on TCP/IP: Ethernet/IP, Modbus/TCP. ProfiNet V1 (CBA)Real-Time mechanisms are embedded in the top layer, limiting the real-time performance.

- Standard Ethernet: Ethernet Powerlink, ProfiNet V2 (RT)Real-Time mechanisms are implemented on top of standard Ethernet (physical and data link) layers, benefitting from the Ethernet evolution without further investment.

- Modified Ethernet: EtherCAT®, Sercos III, ProfiNet V3 (IRT)The standard Ethernet layer (physical and data link), the Ethernet mechanism and infrastructure are modified, putting performance before standard compliance.

Regardless of the individual approach, it is mandatory that each variant maintain the standard Ethernet TCP/IP to assure homogenous networking throughout the manufacturing facility, from office to plant floor, addressing the needs for engineers involved with information technology.

The following image demonstrates the various versions of Ethernet-based industrial protocols and how they deal (or not) with the non-deterministic features of Ethernet TCP/IP, especially CSMA/CD.

The one apparent difference to the standard Ethernet TCP/IP protocol is the implementation of additional Real-Time Data Exchange modules that manage real-time communication either in place or on top of TCP/IP/UDP (as highlighted in the above image).

Still, all protocols continue support for the Ethernet (IEEE 802.3) physical and data layers and TCP/IP/UDP, hence providing an interface to standard information-level networks and meeting the demands for the Ethernet technology plant of the future.

Protocols such as Ethernet/IP and Modbus/TCP appear to be the most vulnerable when it comes to hard real-time control because they inherited all the features that render Ethernet TCP/IP non-deterministic. While the CSMA/CD issue (random delay times after bus arbitration) can be significantly suppressed through the use of Ethernet switches and entirely eliminated through full-duplex Ethernet, these protocols still have to deal with the additional jitter caused by UDP and IP. After all, they perform all of their communications, including real-time data exchange, through the TCP/IP/UDP stack.

Even with careful design considerations and following strict guidelines to the point, their performance regarding hard real-time control may be questionable (Modbus/TCP more so than Ethernet/IP), specifically for fast motion control applications (e.g., robotics). However, they are, without a doubt, suitable for regular motion control applications, the transportation of vast amounts of data in a timely fashion (e.g., vision systems), and the processing of a massive number of I/O signals.

Other protocols, while still keeping compatibility with TCP/IP/UDP, bypass it for all real-time communication.

Ethernet Powerlink circumvents the CSMA/CD issue very elegantly through bypassing the TCP/IP/UDP layers when it comes to real-time communication. Ethernet Powerlink utilizes dedicated and highly deterministic time slices assigned to each node in the network. The result is that only one node transmits data to the bus during its dedicated time slice, while all other nodes have to wait for their turn. This method effectively prevents any message collision and thus eliminates random dwell times. The bypassing of TCP/IP/UDP also eliminates the IP/UDP jitter.

EtherCAT®, however, approached the CSMA/CD problem by eliminating it at the physical level, which, in all consequence, requires the use of dedicated hardware. While an EtherCAT® Master system requires only a regular Ethernet network interface, each EtherCAT® Slave device necessitates the use of an EtherCAT® controller (ASIC or FPGA chip) in place of the standard Ethernet controller. EtherCAT® still uses Ethernet as the physical layer, but the Ethernet messages are passed from node to node (daisy-chain), thus eliminating the need for bus arbitration per CSMA/CD.

Sercos III, given the currently undetermined status of ProfiNet V3 (IRT), is the only other hardware-based Industrial Ethernet implementation besides EtherCAT®, but Sercos III requires individual Ethernet controllers for Master and Slave devices, while EtherCAT® requires it only for Slave devices.

EtherCAT®, Ethernet Powerlink, and Sercos III are without a doubt hard real-time capable, but especially EtherCAT® and Sercos III, by putting performance before standard compliance, will cause significant development efforts when it comes to implementing the protocol into a new automation device. Primarily, third-party vendors feel the impact.

ProfiNet, in comparison to all other protocols as introduced here, has undergone a transition through all previously described scenarios: ProfiNet V1 (CBA) uses standard Ethernet TCP/IP, ProfiNet V2 (RT) bypasses the TCP/IP/UDP layers, while ProfiNet V3 (IRT) utilizes a dedicated Ethernet controller.

Other significant differences between the various protocols include the data transfer organization, network access, and data synchronization, the cycle and jitter times, the supported bus topologies, the dependency on network segmentation devices, and the support for device profiles.

Note: The European flavors of Industrial Ethernet (EtherCAT®, Ethernet Powerlink, and Sercos III) use a Master/Slave configuration. They shine through a high level of complexity, but they are per default suitable for extreme high-speed, high-precision applications, specifically robotics, thus covering a specific and small slice of the North American automation market.

In contrast, Ethernet/IP and Modbus/TCP, the American technologies, shine through a more straightforward design (Modbus/TCP more so than Ethernet/IP) with focus on enterprise networking capabilities (Client/Server configuration), which not only explains one aspect of their popularity, but they are also better suited for a considerably larger slice of the North American automation market.

The selection of the right Industrial Ethernet is highly application-specific, and in case of turnkey solutions, the decision may be more or less political. However, when it comes to high-demanding automation tasks, it is worth comparing the various protocols and how they fit the application requirements. The real-time performance or the attached costs may be the deciding factor.

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...