Recent Posts

Industrial Ethernet Guide - Classification of Industrial Ethernet Protocols

Posted by on

The following is part of A Comprehensible Guide to Industrial Ethernet by Wilfried Voss.

Note: This chapter represents a paradox in so far that it proves that a credible classification of Industrial Ethernet protocols based on performance characteristics, despite many such attempts, does not exist. Too many conflicting performance tests added to the confusion not only for the novice but also for the experts in the Industrial Ethernet industry.

There are two major problems with attempting to standardize and categorize Industrial Ethernet protocols based on performance:

First, the different protocol versions are not interoperable, because they have been developed independently and, with Sercos III being the only exception, they are vividly protected by each manufacturer (because they benefit the most from maintaining a close grip on the technology, despite the existence of official standardization organizations). Secondly, in terms of classification, protocol performances are insufficiently evaluated and compared.

Note: While the various standardization/user organizations agree that users of Industrial Ethernet would greatly benefit from open and standardized technologies, they are, in fact, mainly driven by commercial interests as the Fieldbus wars of the past have demonstrated.

Official classification of the various Industrial Ethernet protocols based on mere technical data does not exist because a fair performance comparison is almost impossible to achieve. Even if there are test results, they will leave more than ample room for discussion, because they are overwhelmingly application-specific.

The Industrial Automation Open Network Alliance (IAONA), an organization that was dissolved in 2006, published their IAONA Real-time Classification based on factors such as latency, synchronization, and bandwidth, however, without attaching any “class” tags to the various existing Industrial Ethernet protocols, because they were not able to sufficiently evaluate and compare performances based on their criteria.

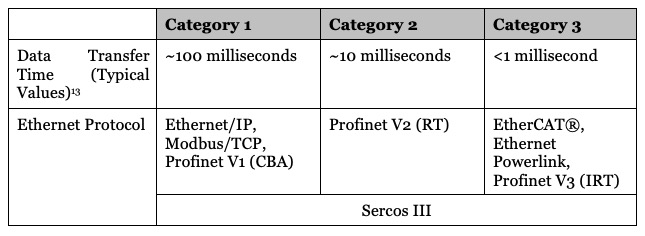

Nevertheless, given possible data transfer times (equivalent to the process cycle time), Industrial Ethernet protocols have been coarsely (and unofficially) classified into three categories as quantified in the following table.

The Sercos III protocol (which was initially not included in the above classification attempt) supports cycle times from 31.25 microseconds to 65 milliseconds (a user setting) depending on the number of slave devices that need to be supported within one cycle.

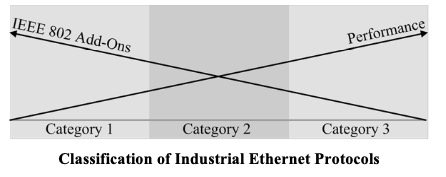

The various protocols become more potent from category 1 to category 3, and the increased performance is the result of added functionality at the TCP/IP Link Layer, accomplished through specific hardware or software. For instance, Ethernet Powerlink implements a Master/Slave support per software (effectively bypassing the TCP/IP/UDP layers for real-time control), while EtherCAT®, Sercos III and ProfiNet IRT go as deep as the physical layer, meaning they require additional hardware.

Category 1 protocols, and to a certain degree those of category 2, depend heavily on add-ons to the IEEE 802 standard to accomplish an evident level of determinism.

However, a classification merely based on data transfer time is not without flaws, since the cycle time can depend on several factors (e.g., number of nodes in the network, use of Ethernet switches, etc.). Sercos III, with its adjustable cycle time does not at all fit into the above characterization scheme. In another scenario, Ethernet/IP with Gigabit Ethernet would significantly improve its cycle time, while EtherCAT, Sercos III, and ProfiNet V3 (IRT) are not immediately suitable for Gigabit Ethernet.

To add to the confusion, other tests have determined an Ethernet/IP “update interval” of only 8 milliseconds, which is consistent with other sources who determined the Modbus/TCP (which is also based on standard Ethernet TCP/IP) cycle time to be 5 to 10 milliseconds.

While typical data transfer times may be an essential indication of the performance of the individual protocols, it does not sufficiently explain the details of how these protocols deal with the most significant challenge when it comes to real-time control, namely the CSMA/CD bus arbitration feature and the UDP/IP jitter.

For example, while EtherCAT® and Ethernet Powerlink are in the same category in terms of data transfer time, they represent fundamentally different approaches to preventing CSMA/CD and bypassing UDP/IP.

Even a classification based on “hard” or “soft” real-time capabilities must fail. First, there are still lively discussions between the various user organizations about the degree of “real” real-time performances of their respective technologies. Secondly, even protocols like Ethernet/IP and Modbus/TCP, which appear to lack determinism, can accomplish hard real-time control when the responsibility for real-time control is with the end devices and not the network (a design feature that is yet again a subject of intense discussions).

The following chapter explains the differences between the individual protocols based on their characteristics and their impact on the TCP/IP protocol layers.

netSHIELD"NSHIELD 52-RE" - Industrial Ethernet Development Platform

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

netSHIELD is an evaluation expansion board with Arduino compatible connectors for development purposes.

It enables the user to connect a Microcontroller based application to all market relevant Real-Time-Ethernet industrial networks with best-in-class real-time capabilities, like PROFINET, Ethernet/IP, EtherCAT, and others.

The extension board features a netX 52 system-on-chip. The netX SoC architecture is designed from the ground up for the highest demands on flexibility, determinism, and performance in terms of multi-protocol capability and low latency for short cycle times. The heterogeneous multi-core architecture features an ARM processor core, coupled with a flexible communication subsystem (xC) for varieties of industrial applications support.

Loading... Please wait...

Loading... Please wait...