Recent Posts

Accelerate Automotive Development with the Teensy 4.0 OBD-II CAN-Bus Simulator

Posted by on

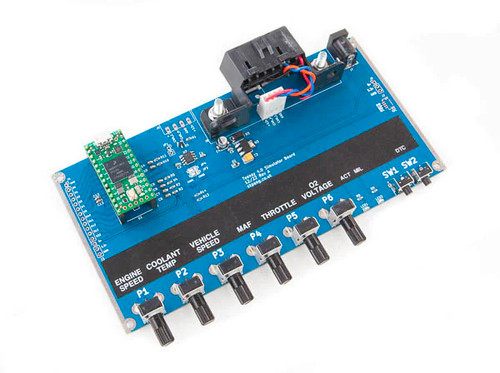

The Teensy 4.0 OBD-II CAN-Bus ECU Simulator by Copperhill Technologies is a compact and powerful tool designed by Copperhill Technologies for automotive diagnostics, embedded development, and CAN bus prototyping. The board comes with a pre-programmed Teensy 4.0 microcontroller and simulates a vehicle’s ECU by generating OBD-II data over the CAN bus, making it highly suitable for development and testing environments.

The Teensy 4.0 OBD-II CAN-Bus ECU Simulator by Copperhill Technologies is a compact and powerful tool designed by Copperhill Technologies for automotive diagnostics, embedded development, and CAN bus prototyping. The board comes with a pre-programmed Teensy 4.0 microcontroller and simulates a vehicle’s ECU by generating OBD-II data over the CAN bus, making it highly suitable for development and testing environments.

This device is particularly useful for developers working with:

-

OBD-II scan tools and diagnostic software

-

Telematics systems and fleet diagnostics

-

CAN-to-USB adapters and gateways

-

Automotive training and education

Hardware Specifications

-

Microcontroller: NXP i.MX RT1062 (Teensy 4.0)

-

32-bit ARM Cortex-M7 core @ 600 MHz

-

1 MB RAM, 2 MB Flash

-

-

CAN Bus Interface:

-

MCP2551 CAN transceiver (Classic CAN at 11-bit/29-bit identifiers)

-

Supports 11-bit OBD-II PID requests/responses

-

-

Power Supply: 7-12 V DC input (via barrel connector)

-

I/O:

-

Standard OBD-II connector (J1962 female)

-

USB Micro-B for power and programming

-

-

Other Features:

-

DIP switches for baud rate and mode configuration

-

Status LEDs for power and CAN activity

-

Pre-loaded firmware for PID simulation

-

Firmware & Software

The onboard firmware emulates a subset of standardized OBD-II PIDs, such as:

-

Engine RPM

-

Vehicle Speed

-

Coolant Temperature

-

Throttle Position

-

Intake Air Temperature

The simulator responds to standard OBD-II requests on CAN ID 0x7DF and replies on IDs 0x7E8 to 0x7EF, following the ISO 15765-4 (CAN) protocol.

Application Scenarios

-

Developer Testing: Validates how custom software or third-party hardware handles standard OBD-II responses without needing a running vehicle.

-

Educational Use: Ideal for training automotive students or engineers on OBD-II diagnostics without exposing them to the safety hazards of live vehicles.

-

Telematics Development: Provides a repeatable, controlled environment to test embedded telematics devices (e.g., GPS trackers, fleet monitoring systems).

-

Regression Testing: Ensures consistent behavior during firmware upgrades or integration cycles for diagnostic software.

OBD-II (OBD2): Technical Overview

What is OBD-II?

On-Board Diagnostics II (OBD-II) is a standardized system implemented in nearly all vehicles sold in the United States since 1996. It provides access to engine and vehicle health information, including real-time sensor data and diagnostic trouble codes (DTCs).

Key Components

-

OBD-II Connector:

-

16-pin J1962 interface, typically located under the dashboard.

-

Provides access to power, ground, and multiple data buses (CAN, ISO9141-2, K-Line, etc.)

-

-

Communication Protocols:

-

Modern vehicles use ISO 15765-4 (CAN) as the default.

-

Legacy protocols include ISO9141-2, J1850 VPW/PWM, and KWP2000.

-

-

PIDs (Parameter IDs):

-

Used to request sensor data.

-

Example: PID 0x0C returns engine RPM.

-

Mode 01 = Current Data; Mode 03 = DTCs; Mode 09 = VIN and Calibration IDs.

-

-

CAN Frame Structure:

-

Requests sent to broadcast ID: 0x7DF

-

Responses returned from ECU IDs: 0x7E8–0x7EF

-

Follows ISO-TP (ISO 15765-2) for longer messages.

-

-

Emissions Monitoring:

-

OBD-II was mandated primarily for emissions-related monitoring.

-

Includes monitors for catalytic converters, oxygen sensors, EGR systems, etc.

-

Usefulness of an OBD-II Simulator

Benefits in Development

-

Controlled Environment: Provides repeatable conditions for software testing.

-

Safety: No risk of interfering with real vehicle systems.

-

Portability: Can be used in labs, classrooms, or on-the-go without a car.

-

Automation: Allows scripting of tests for regression analysis and CI/CD pipelines.

Ideal for:

-

Engineers developing ECU firmware, OBD-II apps, or diagnostic readers.

-

QA teams conducting stress or edge-case testing.

-

Startups in automotive IoT, fleet management, and data analytics.

Conclusion

The Teensy 4.0 OBD-II CAN-Bus ECU Simulator is a powerful, compact, and affordable tool for developers and educators in the automotive diagnostics space. It bridges the gap between software development and vehicle data protocols, offering a safe and flexible environment to simulate OBD-II behavior. Whether you're building a fleet tracking platform or teaching students about diagnostic protocols, this device delivers an efficient and practical solution.

Hyperlinks

This comprehensive guide was developed independently, without sponsorship or endorsement from any specific company or organization. Any references to manufacturers or systems are provided solely for informational purposes to support a better understanding of diagnostic procedures.

Inside, you’ll find an extensive cross-reference of critical automotive sensor values—including MAP (Manifold Absolute Pressure), TPS (Throttle Position Sensor), and FRP (Fuel Rail Pressure). These references make this guide an invaluable resource for automotive diagnostics and repair.

All diagnostic trouble codes (DTCs) included in this publication were meticulously reverse-engineered during the development of our Scan-1 OBD-II Scanner and Diagnostic System. Through our deep experience working with automotive ECMs and Scan-1 software, we’ve compiled what we believe to be the most complete and detailed OBD-II code list available in the industry today.

Because the Scan-1 functions as both a diagnostic tool and advanced scanner, it has generated a significant volume of code data—data we are now proud to present to you in an accessible, affordable format. While our definitions may vary slightly from those found in other publications, they reflect real-world testing and application.

This guide includes:

-

Full generic OBD-II code definitions

-

Detailed code setting criteria

-

Multiple instances of manufacturer-specific code logic

It’s important to note that while generic OBD-II code definitions are standardized across manufacturers, the specific criteria for setting these codes can vary. Where applicable, multiple code conditions are provided—simply analyze them and apply the most relevant one to the vehicle you are servicing.

Whether you're a technician, student, or automotive enthusiast, this guide serves as a powerful tool in navigating and understanding the complexities of modern OBD-II systems. More information...

Loading... Please wait...

Loading... Please wait...